Challenge

The touchscreen is not responding

A client using other display solutions approached us to help them with a problem they faced with the display not responding to touch. They tried to fix it by tuning the controller, increasing sensitivity, and changing the touch event threshold. However, these adjustments caused other issues, such as false touches. Finally, this far-from-perfect solution required users to press the screen very hard to operate the device.

Solution

Selecting an industrial-grade touch controller

For demanding public space applications, it is best to choose industrial-grade technology over consumer-grade. Industrial-grade touchscreen controllers perform better and offer greater control over parameters like signal-to-noise ratio (SNR).

Problem solved—lesson learned

To address the client’s issue, we replaced the existing touch controller with a new industrial-grade model and precisely tuned it.

We also advised project engineers to make this fine-tuning always during the early R&D phase. Additionally, we recommended avoiding design changes, such as adding extra cover glass based only on datasheets, without thorough testing before final production.

Approach

Starting point

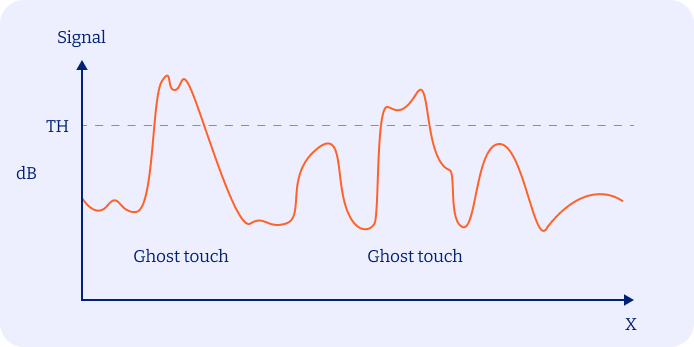

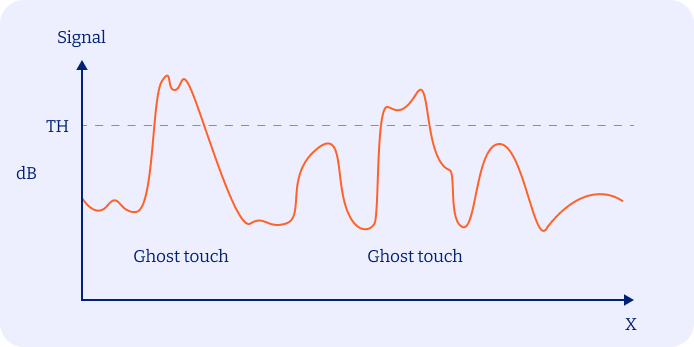

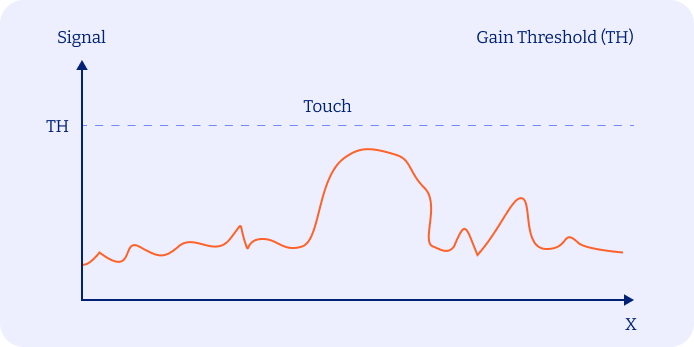

The client started their project using another manufacturer’s consumer-grade controller, which was generally less powerful, making it difficult to eliminate noise and achieve a balance between sensitivity and gain. At first, they increased gain on the controller which raised the overall noise, leading to false touch events that exceed the touch threshold.

To eliminate false touches, reducing the signal gain seemed necessary, but this caused normal touch events to fall below the threshold, requiring users to press really hard to record a touch event. Pressing hard could push the signal above the threshold, allowing the coffee machine to operate.

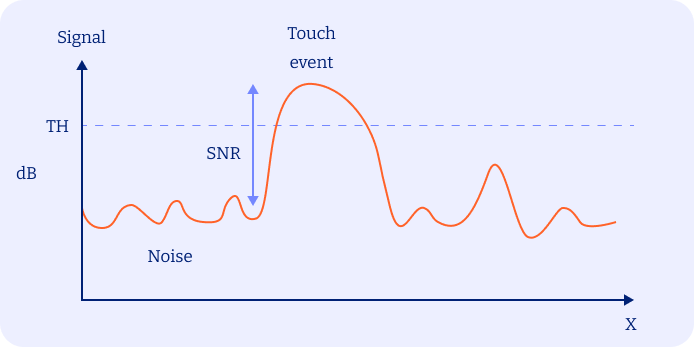

Constantly pressing hard and dealing with ghost touch events due to background noise near the threshold was not ideal for proper touch panel tuning. Which is why the solution here was in optimizing the Signal-to-noise ratio (SNR).

Action

Selecting the industrial-grade controller with higher SNR

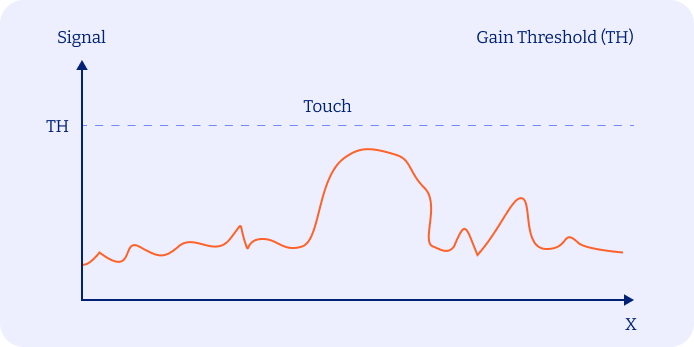

The difference between the background noise that the touch controller can handle and the generated signal is called the Signal-to-noise ratio (SNR). In this case, industrial controllers were a preferred choice due to their higher SNR, measured in decibels. A higher SNR value indicates a better controller. Unfortunately, not all consumer-grade manufacturers provide SNR information in their datasheets. Therefore, well-tested and well-documented display solutions are recommended.

To sum up, industrial controllers have higher SNR than consumer-grade controllers. At Riverdi, all the solutions we offer are industrial-grade. It provided our client with extensive opportunities to fine-tune their final product to perfection.

However, if you are working with other manufacturers, it is suggested to verify the SNR and other parameters during R&D or seek expert advice.

Result & Takeaways

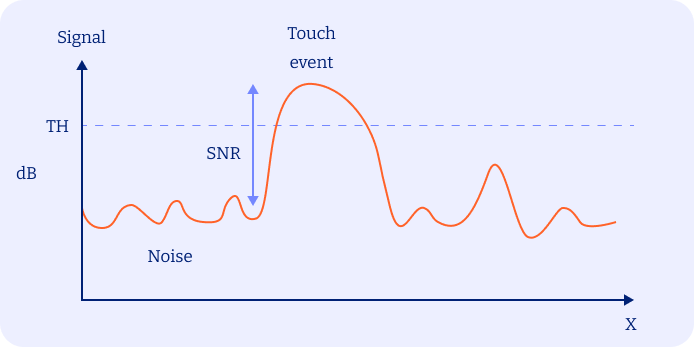

Only real undisturbed touch signals

The overall goal was to tune the touch panel control unit to maintain low noise levels and provide a clear touch signal. We achieved this using our industrial-grade touch controller.

A smooth and successful transition do mass production

Riverdi’s unit proved to be a project’s game changer due to its advanced hardware and software solutions, offering numerous algorithms to eliminate background noise and retain only the pure, unforced touch signal. Thus, each of our client’s final mass-produced coffee machines provided end users with the same positive and uninterrupted experience.

Contact us for an insightful expertise

Contact us now to dive deeper into the industrial-grade outdoor displays for your project. At Riverdi we craft solutions that enhance the value and functionality of your devices. We are happy to discuss and assist you with your design and R&D challenges.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!