Brightness Enhancement Film (BEF) is a specialized prismatic film used in LCD displays to increase the brightness perceived by the user. BEF acts as a controlled “light gate”: it collects dispersed light from the backlight module and directs it toward the viewer, improving the efficiency of the entire optical system. This allows brightness to be increased without raising backlight power, which in turn reduces energy consumption and improves device efficiency.

Mechanism of action: prismatic films, refraction, and reflection

The key functional element of BEF is a layer of micro-prisms with precisely defined angles and density.

- Refraction – as light passes through the prisms, it changes direction and becomes concentrated toward the viewing axis.

- Internal reflection – some rays are redirected and sent forward again.

- Light collimation – reducing the angles of dispersion makes the screen appear brighter for a viewer positioned directly in front of it.

Together, these effects increase the amount of useful light without increasing LED power.

Brightness Increase: percentage gain

In typical configurations, BEF can increase brightness by 40% to even 60%, depending on backlight quality and film parameters.

Even better results are achieved with DBEF (Dual Brightness Enhancement Film)—a dual-function film that also acts as a light-recycling polarizer. DBEF can deliver 70%-100% brightness improvement, especially in high-end systems where maximum energy efficiency is required.

Structure and types of BEF films

Component Layers

A standard BEF consists of several precisely engineered layers.

| Layer | Description |

| Base Layer | A stable polyester or polycarbonate substrate providing rigidity and durability. |

| Prismatic Layer | The core layer containing micro-prism structures responsible for light direction. |

| Hard Coating | Protective layer preventing scratches and degradation. |

| Optional Optical Layers | Filters, anti-reflective coatings, or additional polarizers depending on configuration. |

This construction guarantees high durability, precise light control, and repeatable optical parameters.

Main types of BEF

In practice, three main variants are commonly used:

- BEF (Prismatic Film) – basic version with a single prismatic structure; increases brightness along the front axis.

- DBEF – prismatic film combined with polarization; recovers light normally lost in the LCD module.

- BEF with additional filters/polarizers – used in devices requiring strict control of reflections and scattered light.

These solutions can also be applied in custom designs—provided the end device and its operating conditions justify their use. If BEF or DBEF is the optimal choice, Riverdi engineers will always recommend it.

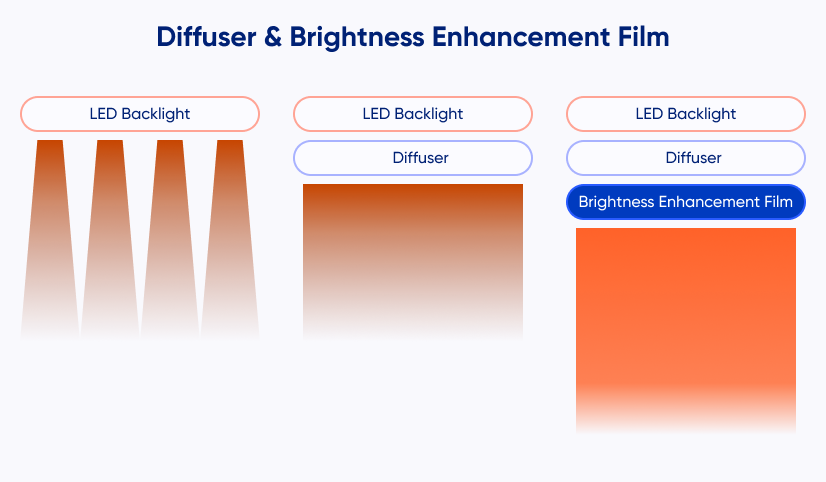

BEF vs. light diffuser: key differences

Although both elements appear in an LCD optical module, they serve completely different purposes.

| Feature | BEF | Light diffuser |

| Function | Increases brightness by directing light forward. | Diffuses light for uniformity. |

| Effect on brightness | Increases brightness. | Does not increase—may slightly reduce. |

| Impact on viewing angle | Narrows toward the front axis. | Widens and smooths the distribution. |

| Application | Energy efficiency, boosting luminance. | Eliminating hot spots and uneven backlight. |

In most LCD modules, BEF and diffusers work together, forming a complete light-management system.

Main benefits of using BEF

Increased brightness and improved energy efficiency

By using BEF, manufacturers can achieve the same brightness while reducing backlight power by 20-40%, resulting in:

- lower energy consumption,

- reduced heat generation,

- longer LED lifetime,

- lower system-level costs.

In battery-powered devices (e.g., medical equipment, portable terminals), BEF is one of the most effective ways to extend operating time.

Better contrast, visibility, and glare reduction

A properly selected BEF:

- reduces scattered light,

- directs light toward the user,

- improves local contrast and readability under strong illumination,

- minimizes the “haze” effect caused by uncontrolled internal reflections.

The result is higher visual quality, especially in industrial, medical, and outdoor applications.

Thinness and light weight

BEF films are extremely thin (typically 60-120 µm) and very lightweight. Therefore, they:

- do not affect module dimensions,

- enable thinner device designs,

- simplify optical stack construction without compromising quality.

This is extremely important for mobile and compact products.

If you need support in selecting BEF, DBEF, or a complete optical stack for your display, our team will gladly analyze your project requirements and recommend the optimal solution. Contact our team.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!