Choosing an LCD display in an industrial project affects interface readability, operator comfort, and device longevity. All LCDs rely on liquid crystal modulation, but different panel technologies vary significantly in color stability, contrast, viewing angles, and response times. Understanding these differences helps you select the right display and avoid common problems in long-life industrial applications.

Types of LCD panels: TN, VA, and IPS

TN (Twisted Nematic) – speed at the expense of image quality

TN is one of the oldest and most affordable LCD technologies. Its main advantage is extremely fast response times and low production cost, making it suitable for simple or budget-oriented devices.

However, TN panels suffer from narrow viewing angles, noticeable color shifts when viewed from above or below, and limited color accuracy. These drawbacks make TN unsuitable for professional or visually demanding industrial applications.

VA (Vertical Alignment) – good contrast and deep blacks

VA panels offer high contrast ratios, deep blacks, and better color reproduction than TN. They are well suited for dashboards, industrial information displays, and applications where contrast readability is important.

The downside is a slightly slower response in fast-moving scenes and minor smearing—but in most industrial contexts, this is acceptable.

IPS (In-Plane Switching) – superior colors and wide viewing angles

IPS provides stable colors and wide viewing angles, which we consider essential for professional devices. At Riverdi, TFT IPS is our standard because it delivers reliability, predictable parameters, and a long lifecycle. We utilize IPS in mobile terminals, operator panels, and medical devices where viewing-angle-independent readability is a priority.

Comparison and classification

TN vs VA vs IPS: comparison table and key differences

| Parameter | TN | VA | IPS |

| Color quality | Low | Medium | High, stable |

| Viewing angles | Narrow | Medium | Very wide |

| Contrast | Low | Very high | High |

| Response time | Very fast | Medium | Fast |

| Price | Lowest | Medium | Higher, justified by durability and quality |

Standard LCDs vs. TFT LCDs: which delivers a better picture?

In our experience, standard LCDs (STN, DSTN) are only viable for very simple devices. Since each pixel isn’t individually controlled, this results in slow response times and limited color quality.

TFT LCD is in a different league. Every pixel has its own transistor, which ensures precise color control, high brightness, and compatibility with touch interfaces and optical bonding. For our clients, this translates to a stable image in challenging environments, with no compromise on durability.

Passive vs active matrix LCDs: principles of operation and applications

Passive-Matrix uses row-column addressing without dedicated pixel control. Low brightness, slow response, and limited color depth—suitable for calculators or simple measurement devices.

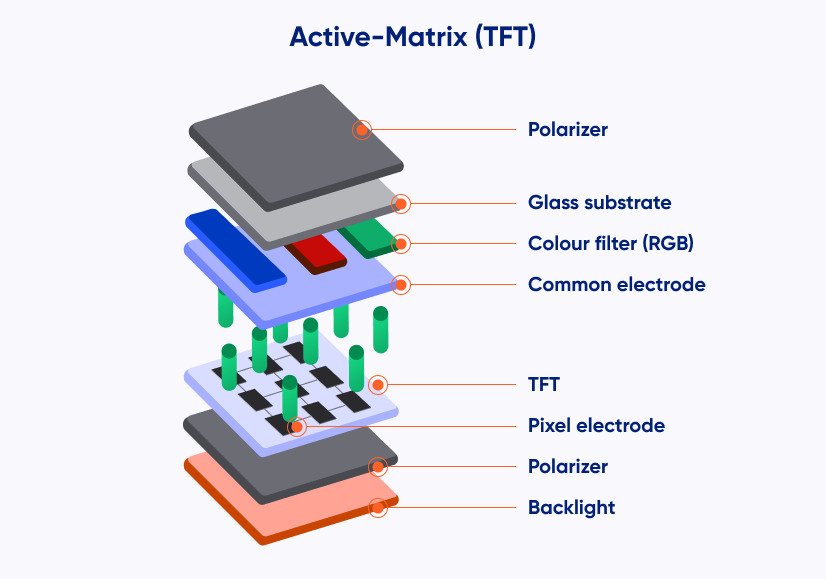

Active-Matrix (TFT) assigns a transistor to each pixel, enabling high brightness, fast response, precise color control, and touch interface support. This is the standard for modern industrial, medical, and professional applications.

Things to know: choosing a panel and busting myths

Key parameters: what to consider when choosing a monitor

When selecting a panel, focus on the:

- viewing angles and color stability,

- brightness and contrast,

- response time and motion clarity,

- operating temperature range,

- backlight lifespan and uniformity,

- compatibility with touch technologies,

- long-term availability and supply stability.

Choosing a display is always a balance between performance, operating environment and budget.

TFT IPS often proves to be the best choice when predictable parameters and long-term performance are critical. In our experience, clients who initially choose passive panels often return to TFT when issues arise with contrast, viewing angles, or backlight durability.

On a side note, let’s debunk a few myths about LCDs.

- TFT is always more expensive – no longer true. Manufacturing improvements have reduced the cost gap, and higher reliability offsets long-term maintenance.

- LCD is outdated – still dominant in industrial and professional markets due to stability, predictable behavior, and customization options.

- All LCDs meet the same standard – specifications alone don’t ensure uniform quality. Differences exist in backlight life, environmental resistance, and color consistency. Verification is the key in industrial projects.

If you need help selecting the right panel, the Riverdi engineering team can guide you through the process and recommend the best solution for your application and budget. Contact us.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!