Don’t press too hard – introduction to the problem

Let’s imagine you have a touch screen on your new product – a coffee machine. The device is not working properly, because the display is not responding to touch. To make it work you try tuning the controller – by increasing the sensitivity and changing the threshold. But by doing so you end up with other issues, like ghost touch effect. Finally, your solution is to press the screen really hard. And you put a sign on the coffee machine, saying:

TO MAKE COFFEE – PRESS HARD :(

You may still wonder, how can you make it work right. Yes, there is a way.

In this article, we’ll show you what was the root of the problem and how you could have avoided it. Here are the two major takeaways, but please read on to clarify them:

TAKEAWAY #1: To make precise tuning to a touch screen controller you need to do it during an early R&D stage. Avoid changes in design (like adding extra cover glass based only on datasheet) without having them thoroughly tested before production.

TAKEAWAY #2: When you choose your touch screen controller for demanding applications – always prefer industrial over consumer grade. Industrial grade will perform better and allow you more control over parameters like SNR.

What happened in the device design process?

To know what is the exact source of the described malfunction we need to turn to theory behind the practical solutions. Before we proceed, let’s go through what exactly happened, step-by-step:

- You ordered the display to test it and the prototype worked well.

- Then, during manufacturing process you added the extra layer of cover glass, which according to datasheets should work fine, and something went wrong.

- To solve the problem you decide to increase the sensitivity of touch screen controller.

- Unfortunately, it doesn’t help – the device starts to react chaotically and you end up with a ghost touch effect.

- Then you lower back the gain of touch screen and decide to press your finger harder, every time you want to make a coffee.

Looks reasonable, so what’s to blame? Let’s find out by zooming in each step.

Focus on the R&D, design and production

First, what is the display you ordered? In the above mentioned example the display is equipped with a consumer grade touch screen controller. That’s quite important in terms of several parameters, like signal-to-noise ratio (SNR), which will be explained later.

Second, adding extra glass seems to be the problem. But why is that, since the touch screen controller should handle this amount of glass? The question is: how did you add the glass? What was the bonding method? Was it air bonding or optical bonding? In this case the additional layer of cover glass was air bonded. It means, that there is a thin layer of air between the two bonded glasses. As we will explore later, that is the second most important factor influencing proper functioning of this coffee machine’s touch screen.

Third, where does the ghost touch effect come from? It’s because the controller is tuned to high sensitivity (gain) and interprets noise as touch events. This will be clarified later, when we’ll explain the tuning process.

Lastly, what actually happens when you press your finger harder on the capacitive touch screen? Why it is not the go-to solution for increasing the touch signal? We’ll cover that too.

But now let’s pull back and start over with the basics of touch screen and a little bit of theory behind it. This will allow us to nail and understand the design mistakes made in the example we focus on in this article.

The basics of how the touch screen is built and how it works

To solve the problem of touch screen not working properly, you need to understand the basics how the touch screen is built. Then you will learn what is happening when you put a finger on top of the glass.

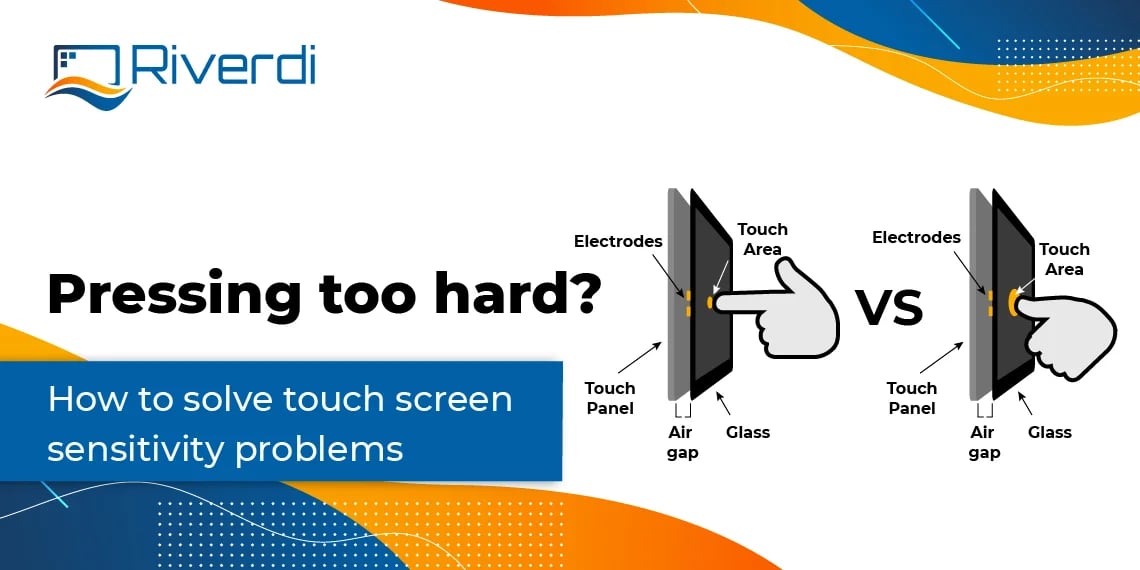

The two rectangles on the drawing are the electrodes, which are Indium Tin Oxide (ITO) on the glass. You can visualize those electrodes as two electrical lines on the glass (the lines are transparent, but they are there), which are connected to the touch screen controller. The touch screen controller is measuring the mutual capacitance between these two electrodes.

On top of the electrodes, there is a glass, which actually is made of two glasses – one glass is usually the sensor glass and the other one is the cover glass. For the sake of simplifying you just see one glass on the drawing – the one that you touch.

What is happening when the finger is touching the glass?

The finger is adding additional capacitance to the mutual capacitance of these two electrodes. In the drawing the capacitances C1 and C2 are being added to the total capacitance measured by the controller. When you touch your finger there the mutual capacitance in this area will increase. This is what you are measuring with your controller and that’s why you know where exactly the finger is touching the screen.

How does the touch influence the capacitance?

The formula below shows in theory what is happening inside the touch screen controller.

To calculate the capacitance you need an ε (epsilon) zero, which is permittivity of the void, then multiplied by ε (epsilon) r, which is permittivity of the glass. In this case, it’s the cover glass. Next, have it multiplied by A (area) of the electrodes divided by d (distance).

The distance between the electrodes and the finger will be the d. Typically the distance in touch screen is one millimeter up to three millimeters – depending on the project you work on and the cover glass thickness that you use. Other parameters in the formula will stay constant. When you have the glass thickness sorted out in the project, then the d (distance) also will stay constant.

How this formula works in touch screen?

What would be the variable in that case? The touch area. When you press your finger to the glass, you are adding extra capacitance to the overall value that the controller is measuring (to the constant, idle internal capacitance). In a typical situation, when you power on the touchscreen, the device is measuring all the capacitances between the electrodes and it’s making something like a reference point (or the starting, idle state of the touchscreen). What is measured as the touch event is only the extra capacitance.

Let’s say the device is measuring few picofarads of idle capacitance, because it’s a typical value for the capacitance of the electrodes. This is a constant used as a reference. When there is no touch, no finger on the screen, the extra capacitance equals zero, because the touch area is zero. There is just the internal capacitance.

Once you touch the screen, the touch area will not be zero anymore. When you push the finger, you add some extra capacitance. Sometimes, when you have issues with touch screen performance, you start pushing harder.

Will pressing hard help?

Sometimes, when you have issues with touch screen performance, you start pushing harder. What actually happens when you press your finger harder? In this case the capacitive touchscreen does not measure the mechanical force, it measures area where the touch event occurred. When you touch the screen gently, then the area of your finger is rather small. When you press harder, you increase the area by squeezing your finger on the surface, thus you increase the overall signal.

But it’s rather non-practical and not recommended solution. There are better ways to increase the touch signal.

What will happen when you air bond extra layer of glass?

Let’s have a look what happens when you add extra layers, like air and the cover glass, on top of the touchscreen. Let’s assume you have added an extra 3 mm glass using air bonding method. In between there is a small air gap separating two glasses, like only 0,2 mm, but it makes quite a difference.

Then on the bottom there is still the touchscreen cover glass of the of 1 mm. With an extra layer changes the total distance between the finger and the electrodes.

How does touchscreen change with extra layer of glass?

How does extra layer and distance in given example influence the electrical field between finger and electrodes? First of all, you should be aware that air is pretty bad for the electrical field. To show you how bad, let’s calculate that with the same capacitance formula.

One glass is pretty simple to calculate. It is just one millimeter glass. The other glass is quite simple as well. The added glass is a three millimeter glass, so the overall distance is already four times bigger than before. But there is also thin air in between those glass layers, which means you need to calculate the equivalent of the 0,2 mm air gap into the glass distance.

How to calculate capacitance change due to distance changes?

The distance will influence the capacitance measured by the touchscreen controller.

Quick recap: The capacitance equals permittivity of the void multiplied by relative permittivity and then multiplied by the area of the capacitance and the distance between the electrodes.

The three layers have different relative permittivity. To calculate the distance that air is actually influencing the electrical field you can convert it to “glass units”. It means, that you will present air distance as a glass distance. Because then you will know how to properly tune your touchscreen controller. To do that you will need to understand the differences of permittivity in glass and air.

Permittivity explained

It’s time to clarify the permittivity in touch screens. The permittivity of the glass is between six and seven, for the sake of calculations. Typically, you can assume seven, and the permittivity of the air is the same as void. That is the relative permittivity, which is just one. In that case, the air does not increase the electrical field.

The glass is seven times better than the air to move electrical field. It means that air needs to be around seven times thinner than the glass to be equivalent in this matter. In other words, the glass can be seven times thicker than the air to have the same equivalent distances in terms of permittivity. When you include ε (epsilon) r into the distance formula you can calculate the actual distance – the distance between the electrodes and the finger that is touching the screen

The d (distance) is a distance that equals 1 mm. Plus on the other side there is also glass and it’s 3 mm. Plus the air gap that is in between – 0,2 mm.

Next, multiply the air gap by seven, because glass is seven times better to move electrical field than the air, and altogether it is the real glass equivalent distance. It will be 1 plus 3 equals four and 0,2 multiplied by 7 is 1,4 mm.

In total it’s 5,4 mm. Now we know how the distance changed. From 1 millimeter of original touch screen by adding glass you moved to the 5,4 millimeter, which is pretty thick.

Quick recap: When you add extra glass using air bonding method, you need to consider the air gap as an additional layer between the touch event and the touch screen sensor. It will impact the signal received in way described in above formula. In short – the air gap calculates into more “glass” – more than what it actually measures in mm.

The distance change is more than five times and the touch control now has this problem to recognize the finger touch, because the signal – the capacitance, that is being added to the internal capacitance – is very small.

How can you change the signal by tuning touch screen controller?

In the example of coffee machine described in the beginning there were steps taken by the engineer to regain control over the touch screen. To recap – he tried to tune the signal by increasing its gain, but it resulted in ghost touch effect. Then he lowered the sensitivity back and tuned it a way that enabled the device to make coffee, but only when you press the screen really hard.

Now you can learn on this example how the signal in touch screen is made and how you can have it regulated.

How does the touch screen controller signal look like?

Let’s have a closer look how the signal inside the controller work. To make effective tuning you need to know what is happening with the signal you are about to adjust. The controller is measuring the mutual capacitance between electrodes. And when you press with the finger, the capacitance changes and is being processed into the signal. The signal is representing the capacitance on the touch screen and between electrodes.

For the purpose of explanation the signal has just one dimension on the chart.

Let’s start with the noise – how does it affect the signal

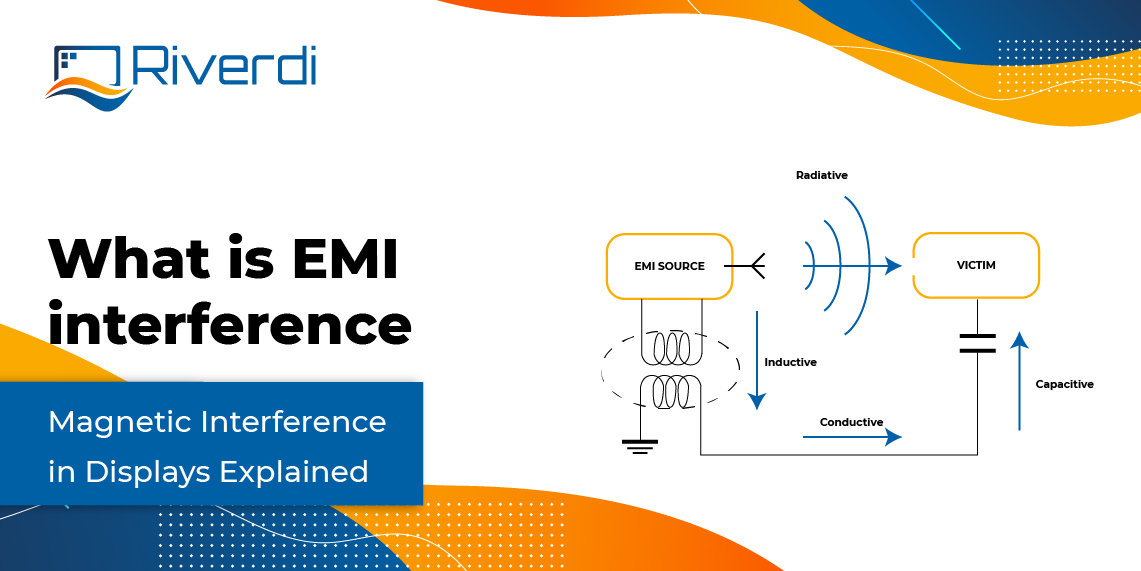

The line that we see here is an example of an idle signal, measured by the touch control when there is no finger touching the screen. It’s measuring the noises coming from the background, or the noises coming from the internal circuit. It is so, because the capacitive touchscreen is in a way like a sensitive antenna and it’s receiving a lot of different environmental signals. Those noises will always be there and by changing the signal gain you will also change the overall noise level.

How the signal changes when you touch the screen?

Let’s say somebody is touching the screen. What is happening then? There will be a signal that is clearly above the noise level. In the touch screen, there are many parameters depending on the controller, but the most basic are gain and treshold. Gain represents how the measured signals are internally amplified by the controller. The threshold, typically called TH (threshold signal), is the minimum level of the signal to be recognized as a touch on the screen.

By increasing the distance from the electrodes to the screen (for example by adding additional glass) the overall signal will be decreased. When the noises (along with standard signals) are way below the threshold level you will not receive the actual touch signal. The touch event takes place only when the threshold is exceeded.

Will increasing the touch screen gain help?

With the signal level below threshold the touch screen will not work. What you need to do is to increase the gain, increase the signal or decrease the threshold. What will happen if you increase the gain? After increasing the gain (or sensitivity) you will end up with the touch signal above the threshold level. You can now sense the touch and this is what you wanted.

Or is it? Something is still wrong. What is happening when you increase the signal gain level?

Quick recap: Unfortunately, as we mentioned before, you have used a consumer grade touch controller. In consequence, if you increase signal sensitivity too much, you will also boost the overall noise level – close to the threshold level!

The unfortunate case of ghost touch effect

When noises are very close to the threshold, or occasionally above the threshold level, they might be treated by the controller as the proper signal, not noise. Then you will have the situation called a ghost touch or phantom touch. And you definitely don’t want that. Nobody wants the coffee to be made by itself (or ghosts). And in number of industrial or medical applications it could even be dangerous.

Balancing sensitivity and gain

What you need to do is to balance this sensitivity (or gain) to keep the touch signal above the threshold, but at the same time to keep the noises always below the threshold level.

Quick recap: You have used the thick glass and you need the signal level to be high in order to reach the required threshold line. And you have consumer grade controller, which is a weak controller, it will not be able to remove the noises and push them down.

At this point, what you want to achieve is to balance the sensitivity and gain. In consumer grade controllers that is nearly impossible. This kind of device will not be equipped with settings that enable proper balance between gain and sensitivity.

That is why you end up with pressing hard. Why? Pressing hard is increasing the area of the finger on the touch screen. It will make the signal of the total capacitance a little bit higher. When you press hard the signal may turn up to be above the threshold level and the coffee will be made.

Pressing hard is not the ideal situation, of course. The noises or the background noise is probably too close to threshold. And sometimes it may happen that you will have occasionally a phantom touch, but at the same time, your touch screen is not sensitive enough. And you really want to be gentle with your touch screen.

You don’t want to push hard always – it is not the goal of right touch panel tuning. So what now? Let’s dive into the SNR – signal to noise ratio.

What is SNR? The art of taming the signal to noise ratio

The difference between the noises of the background that control is able to handle and the signal that is generated is called an SNR – signal to noise ratio. The industrial controller is better because it has higher SNR. Typically you measure SNR in decibels. Higher dB value indicates better controller. Unfortunately, not all manufacturers inform about the SNR in their datasheets.

In general, you can expect that the industrial controller will have higher SNR than the consumer grade controller.

Advantages of industrial grade touch screens

Your general goal in tuning the touch panel control unit is to keep the noise low to have very clear signal. You need to process the signal and have ability to remove the noise from the signal. It’s done both on analog part of the controller, but also on digital part. In terms of signal processing, there are many algorithms in advanced controllers that can help you with noise removal. In Riverdi we use touch controllers equipped with algorithms that can remove the background noises and leave only the clear touch signal.

TAKEAWAY RECAP #1: To make precise tuning to a touch screen controller you need to do it during an early R&D stage. Avoid changes in design (like adding extra cover glass based only on datasheet) without having them thoroughly tested before production.

TAKEAWAY RECAP #2: When you choose your touch screen controller for demanding applications – always prefer industrial over consumer grade. Industrial grade will perform better and allow you more control over parameters like SNR.

Those were the general principles of how does the touchscreen signal control work. Why it cannot be achieved with the simple controller? Because you are not able to keep the signal to noise distance wide enough. When you are increasing the glass thickness, then the signal goes down. You can increase sensitivity and gain. But at the same time the noises are going up and are too close to this dangerous area when you might have the phantom or ghost touches.

If you want to know more about fine-tuning and choosing the right touch screen parameters – please contact us!

Learn more about Riverdi displays with PCAP touch screen solutions: