- What is EMI interference? Magnetic Interference in Displays Explained: Guide to EMI reduction

- What is Magnetic Interference?

- How EMI Interference Affects Display Technologies

- Key Sources of Electromagnetic Interference

- Strategies for Mitigating EMI in Displays

- Regulatory Standards

- Specific EMI Reduction Measures for Display Technologies

- Mitigating EMI in Various Contexts

- Mitigating Electromagnetic Interference in Display Technologies: A Focus on Various Contexts

- Riverdi Product Catalog Overview

- Mitigating Electromagnetic Interference with Riverdi Displays

- Proper EMI Remediation Process

- Recommendations for Electronic Engineers Designing LCD Displays with EMI Mitigation

- Advice for Designers of Home Appliances and Industrial Devices on Mitigating Electromagnetic Interference (EMI)

- Maintaining Display Reliability and Image Quality

- Summary: Mitigating EMI in Home Appliances and Industrial Devices

- FAQ: Mitigating Electromagnetic Interference in Display Technologies

What is EMI interference? Magnetic Interference in Displays Explained: Guide to EMI reduction

You may ask yourself what is EMI? Electromagnetic interference (EMI) in electronics can disrupt the performance of electronic displays and cause distorted images, flickering, discoloration, and other issues. As display technologies advance and become more ubiquitous across industrial, commercial, and consumer devices, mitigating EMI is crucial for reliability and visual quality. This article explores what causes EMI, its effects on various display types, and what is EMI in electronics in general. We also explain how to stop electrical interference, and how to reduce electromagnetic interference with effective strategies to reduce electromagnetic interference.

What is Magnetic Interference?

Electromagnetic interference, also called radio-frequency interference (RFI), occurs when electromagnetic fields disrupt the operation of electronic equipment. EMI can be produced by both natural and artificial sources.

Natural sources include solar flares, lightning, and other electrostatic discharges. Artificial sources encompass just about every electronic device, including motors, power supplies, radio transmitters, integrated circuits, cables, and more. These devices generate electromagnetic fields that can couple onto adjacent components and induce currents that cause EMI.

The electromagnetic spectrum covers frequencies from below 3 Hz to above 300 GHz. Emi interference can occur at any frequency but is especially problematic in equipment operating at radio frequencies between 3 kHz and 300 GHz. Fields at lower frequencies generally do not couple efficiently onto circuits and cables.

How EMI Interference Affects Display Technologies

Displays are particularly susceptible to EMI for several reasons:

- High operating frequencies of display electronics increase sensitivity. Graphics processing units, video processors, and display drivers operate at frequencies exceeding 1 GHz, enabling interference.

- Integration of multiple components in tight spaces raises interference coupling. Displays pack advanced electronics into compact form factors, bringing susceptibility sources close together.

- Growing use of touchscreens adds exposure. Touch sensors placed on screens act like antennas that can pick up electromagnetic disturbances.

- Increasing display resolutions demand more bandwidth and faster processing, increasing possibility of disruption.

EMI can manifest on displays in various ways depending on the display technology:

LCD Displays: Flickering backlight, horizontal or vertical lines across the screen, discoloration, image distortion

OLED Displays: Flickering pixels, mottled discoloration, stripes on display

E-Paper/E-Ink Displays: Ghosting artifacts, slow refresh rates, display freezing

CRT Displays: Warping and distortion of image, color fringing

Projector Displays: Flickering, color shifting, dark areas on projected image

LED Displays: Flickering lights, double images, light color distortion

Plasma Displays: Buzzing speakers, image flickering, brightness fluctuation

Touchscreen Displays: False or missed touches, unintended swipes and taps

The consequences of EMI interference in displays include eye strain for users, defects and malfunctions, product returns and replacements, and overall system failures in critical applications like medical monitors and aircraft cockpits.

Key Sources of Electromagnetic Interference

To tackle EMI issues in display systems, it’s important to understand the major sources that cause EMI:

- External Sources: These include other electronic devices, power lines, and even natural phenomena like thunderstorms.

- Internal Sources: Components within the display system itself, such as power supplies and signal processors, can also generate EMI.

- Crosstalk: This occurs when signals from one circuit interfere with those of another within the same device.

Examples of magnetic interference sources sources

- AC Power Lines: The alternating current flowing in power cables generates electric and magnetic fields that can couple interference onto display circuits.

- Motors and Pumps: Electric motors found in devices like fans, hard drives, and pumps emit EMI through power leads as well as radiated fields.

- Radio Transmitters: Nearby wireless devices including mobile phones, walkie-talkies, Bluetooth, and Wi-Fi routers radiate radio signals that can disrupt display operation.

- Microwave Ovens: High-power microwave radiation emitted by ovens for heating food can penetrate display enclosures and cause interference.

- Electrostatic Discharge: Static charge build-up on cables, circuit boards, user’s fingers, etc. leads to ESD spikes when discharged that induce glitches in displays.

- Lightning: Nearby lightning strikes induce extreme electromagnetic transients and surges that can cause EMI.

- Solar Events: Coronal mass ejections and solar flares emit bursts of electromagnetic energy that can interfere with displays through coupling onto long cables and wires.

- Vehicles: Ignition systems, alternating current motors, and radio transmitters on vehicles produce EMI that pose problems for displays in automotive, marine, and aerospace contexts.

Strategies for Mitigating EMI in Displays

Once we have general concept of what is EMI in electronics, we can start working on minimizing the impact of electromagnetic disturbances on display performance. It involves strategies focused on the three coupled elements that enable EMI – source, path, and victim.

Reduce EMI Sources

Limiting generation of electromagnetic interference in the first place can help prevent issues:

- Use motor noise suppressors and filters on motors and variable frequency drives that produce EMI.

- Keep wireless transmitters like mobile phones away from display equipment or switch devices to airplane mode.

- Only operate microwave ovens away from displays and not while displays are being used.

- Install surge suppressors to limit ESD transients. Use antistatic mats and wrist straps for electronics assembly.

- Utilize lightning protection and surge suppression on power lines to limit spikes from lightning strikes.

Block EMI Paths

Interference coupling paths can be blocked to stop EMI from reaching displays:

- Keep cables short to limit paths for electromagnetic coupling. Long video, power, and data cables act like antennas.

- Use shielded cables with grounded mesh or foil shields to contain EMI interference within cables. Fiber optic cables block EMI over long runs.

- Enclose displays and electronics in grounded metal cases to block radiated external fields.

- Separate and orient susceptible circuits orthogonally to potential interference sources like motors and cables.

- Interconnect grounding helps limit ground potential differences that cause EMI. Bring grounds to single point.

- Route cables neatly and avoid grouping power and signal cables which can capacitively couple.

Make Displays Less Susceptible

Hardening displays against EMI can prevent interference issues:

- Filter signal inputs and power supplies to block coupled EMI. Install line filters on AC power.

- Use metal oxide varistors (MOVs) and transient voltage suppressors (TVS) to clamp EMI transients.

- Choose display power supplies with sufficient headroom and hold-up time to ride-through power glitches.

- Select display electronics and integrated circuits with EMI immunity and hardening. Enable built-in EMI protections.

- Reduce conductive emissions through techniques like spread spectrum clocking, slew rate control, lower voltage swings, shielding, and spectral purity.

- Design circuit layouts carefully by minimizing ground path lengths, reducing current loop areas, and preventing impedance mismatching.

Shielding

- Faraday Cages: Enclosing sensitive components in a conductive enclosure can prevent external EMI.

- EMI Coatings: Special coatings can be applied to the screen and internal components to reduce EMI.

Filtering

- Low-pass Filters: These can be installed to allow only signals below a certain frequency to pass.

- Ferrite Beads: These can be attached to cables to suppress EMI.

Grounding

- Proper Grounding: Ensuring that all components are properly grounded can significantly reduce EMI.

- Ground Loops: Avoid ground loops as they can act as antennas that pick up unwanted signals.

Component Selection and Layout

- High-quality Components: Use components that are designed to minimize EMI.

- Component Placement: Strategic placement of components can help in reducing the paths for EMI.

Software Solutions

- Signal Processing: Advanced algorithms can be used to filter out the noise from the desired signal.

- Frequency Hopping: Changing the frequency of operation can also mitigate the effects of EMI.

Regulatory Standards

Adhering to regulatory standards like FCC in the USA, CE in Europe, and CISPR internationally can also help in EMI mitigation.

Mitigating EMI in display technologies is crucial for ensuring optimal performance and longevity. Through a combination of shielding, filtering, grounding, component selection, and software solutions, the effects of EMI can be significantly reduced. Adherence to regulatory standards is also essential for both compliance and performance optimization.

Specific EMI Reduction Measures for Display Technologies

Implementing EMI mitigation measures requires an understanding of the vulnerabilities of different display technologies:

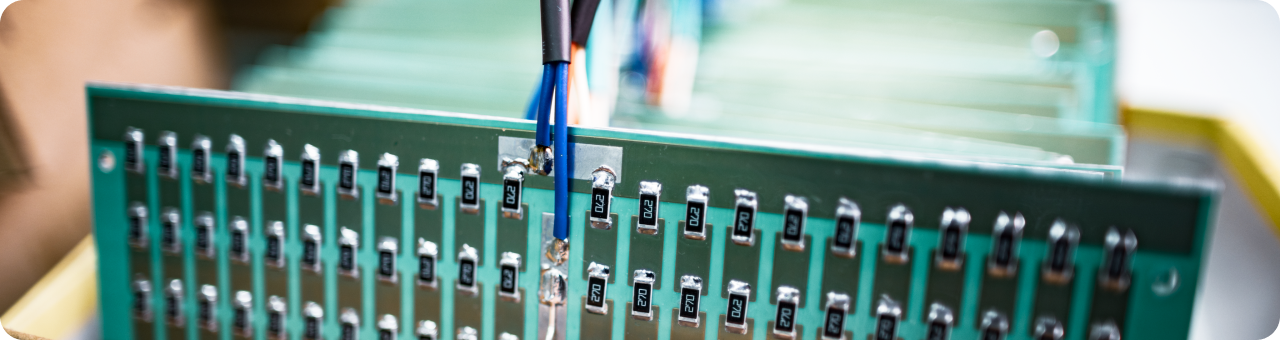

Liquid Crystal Displays (LCD)

- Use multilayer flex cable with ground plane or metal-backed LCD instead of unshielded flex cable.

- Place EMI gasket between LCD panel and frame/bezel interface for shielding.

- Install EMI film or mesh shielding on front and/or rear of LCD glass.

- Use LCD inverter with high input voltage tolerance and EMI filtering.

- Enable overdrive voltage and timing compensation circuits to counteract EMI interference effects on LCD image.

Organic Light Emitting Diode (OLED) Displays

- Employ metal mesh EMI shielding integrated into OLED stack up directly on glass.

- Coat front-side of OLED panel with transparent conductive oxide layer or graphene to reduce electromagnetic interference.

- Use grounded dedicated EMI shielding foil layer underneath OLED stack up.

- Insert EMI absorber sheet material like ferrite polymer into OLED lamination layers.

- Apply EMI gasket sealing around edges and enclosure seam gaps.

E-Paper/E-Ink Displays

- Rewrite display firmware and add capacitors to counteract EMI by resetting display.

- Employ supplementary integrated circuits to detect and compensate for EMI effects.

- Mount EMI shielding film with transparent conductors on display.

- Use shielded cables and appropriate EMI gasket seals on enclosure.

- Relocate components generating interference away from E-paper electronics.

CRT Displays

- Use high quality properly grounded shielded cables like RG-6 coaxial cable for video signal.

- Install ferrite chokes on cables near CRT electron gun to prevent RF ingress.

- Apply conductive EMI shielding paint on interior and exterior of CRT tub envelope.

- Employ deflection yoke with integrated magnetic shielding.

- Increase spacing between electron gun, deflection coils, and power supply transformer.

Projector Displays

- Install EMI shielding on projector chassis like speaker grill mesh or conductive plastics.

- Filter projector input and output cables, especially unshielded VGA.

- Maintain suitable distance from potential interference sources like motors and wireless devices.

- Use surge protectors and cable chokes at power inlet to suppress electromagnetic interference.

LED Displays

- Specify LED driver electronics with sufficient EMI filtering and immunity.

- Keep driver cables short or use shielded twisted pair cables. Ferrite beads can reduce EMI.

- Use mesh metal back shield behind LED pixel array.

- Mount LED display on grounded metal enclosure and avoid plastic housings.

- Separate LED power and data cables from each other.

Plasma Displays

- Use EMI suppressing mainboard layout designs and components. Shield processors.

- Add EMI filtering components on all cable interfaces, especially AC power.

- Apply conductive EMI gasket seals around the display perimeter and enclosure.

- Utilize shielded plasma display panel (PDP) chassis and mechanisms for EMI blocking.

- Increase distance between PDP electronics and power supply transformer.

Touchscreen Displays

- Use touchscreen controllers with built-in EMI immunity and noise reduction capabilities.

- Properly ground touchscreen front panel and employment top EMI shielding when applicable.

- Install ferrite chokes and filters on controller wiring to suppress electromagnetic interference.

- Route touchscreen signals separate from power and motor cabling.

Mitigating EMI in Various Contexts

Home Appliance Devices

In the realm of home appliances, smart refrigerators, ovens, and even washing machines now come with digital displays. EMI can cause these displays to malfunction, leading to incorrect readings or unresponsive touch panels. To mitigate EMI in this context, manufacturers often employ low-pass filters and ferrite beads. Additionally, using shielded cables for internal wiring can significantly reduce conducted EMI. Consumer appliances also need to adhere to specific EMI/EMC standards, such as the FCC Part 15 in the United States, to ensure they do not interfere with other household electronics.

Industrial Devices

Industrial settings are often rife with EMI due to the presence of heavy machinery and complex electrical systems. Displays used in control panels and monitoring systems are critical for operations and must be immune to EMI. In such environments, robust shielding techniques like Faraday cages and EMI coatings are often employed. Software algorithms are also used to filter out noise from critical signals. Industrial devices usually have to meet stringent EMI standards like the IEC 61000 series.

Military Applications

In military applications, the stakes are even higher. Displays are used in everything from handheld devices to control centers and vehicle dashboards. Given the critical nature of these applications, military standards (MIL-STD) for EMI are incredibly stringent. Advanced shielding materials like mu-metal are often used, and the devices undergo rigorous testing to ensure they are EMI-resistant. Frequency hopping and encryption are also employed to secure the signals against both EMI and intentional jamming.

Marine Environments

Marine displays used in ships and offshore platforms must contend with both natural and man-made EMI sources. Saltwater is a good conductor of electricity, and the marine environment is often electrically noisy. To combat this, marine displays are usually housed in corrosion-resistant, conductive enclosures that act as Faraday cages. They also employ advanced signal processing algorithms to distinguish between legitimate signals and noise.

Medical Devices

In medical settings, EMI can be life-threatening. Displays are used in various diagnostic and monitoring equipment like MRI machines, ECG monitors, and infusion pumps. The use of low-EMI components and meticulous circuit design are standard practices in the medical industry. Medical devices have to comply with stringent standards like the FDA’s EMC guidelines in the United States or the Medical Device Directive (MDD) in Europe.

Whether it’s a smart refrigerator in your kitchen or a critical display in a military operation, the need for EMI mitigation in display technologies is universal. By understanding the specific challenges posed by different environments—be it home, industrial, military, marine, or medical—manufacturers can employ targeted strategies to mitigate EMI effectively. This not only ensures the reliability and longevity of the display technologies but also safeguards the integrity of the systems they are a part of.

By adhering to industry-specific standards and employing a multi-faceted approach to EMI mitigation, we can pave the way for safer, more reliable display technologies across all sectors.

Mitigating Electromagnetic Interference in Display Technologies: A Focus on Various Contexts

Key Takeaways

- EMI is a universal issue affecting display technologies across sectors.

- Different environments pose unique challenges and require targeted mitigation strategies.

Home Appliance Devices

- Common Displays: Smart refrigerators, ovens, washing machines.

- Key Mitigation Strategies:

- Low-pass filters

- Ferrite beads

- Shielded cables

- Regulatory Standards: FCC Part 15 in the United States.

Industrial Devices

- Common Displays: Control panels, monitoring systems.

- Key Mitigation Strategies:

- Faraday cages

- EMI coatings

- Software algorithms for noise filtering

- Regulatory Standards: IEC 61000 series.

Military Applications

- Common Displays: Handheld devices, control centers, vehicle dashboards.

- Key Mitigation Strategies:

- Advanced shielding materials like mu-metal

- Rigorous EMI testing

- Frequency hopping and encryption

- Regulatory Standards: MIL-STD for EMI.

Marine Environments

- Common Displays: Ship navigation systems, offshore platform monitors.

- Key Mitigation Strategies:

- Corrosion-resistant, conductive enclosures

- Advanced signal processing algorithms

- Unique Challenges: Saltwater as a conductor, electrically noisy environment.

Medical Devices

- Common Displays: MRI machines, ECG monitors, infusion pumps.

- Key Mitigation Strategies:

- Low-EMI components

- Meticulous circuit design

- Regulatory Standards: FDA’s EMC guidelines in the United States, Medical Device Directive (MDD) in Europe.

Conclusion

- Universal Need: EMI mitigation is essential across all sectors for reliability and longevity.

- Targeted Strategies: Understanding specific challenges allows for effective EMI mitigation.

- Regulatory Adherence: Compliance with industry-specific standards is crucial.

By focusing on these key points, manufacturers and users can ensure that their display technologies are not only visually stunning but also reliable and free from interference, regardless of the application or environment.

A table with the most important parameters and their typical values in context of Mitigating Electromagnetic Interference in Display Technologies in home appliance devices, industrial devices, military, marine and medical devices.

Parameter | Home Appliances | Industrial Devices | Military Applications | Marine Environments | Medical Devices |

Common Displays | Smart refrigerators, ovens, washing machines | Control panels, monitoring systems | Handheld devices, control centers, vehicle dashboards | Ship navigation systems, offshore platform monitors | MRI machines, ECG monitors, infusion pumps |

Shielding Material | Aluminum Foil | Faraday Cages | Mu-metal | Corrosion-resistant Alloys | Medical-grade Shielding Material |

Filter Type | Low-pass Filters | Low-pass Filters | Band-pass Filters | Advanced Signal Processing | Low-pass and High-pass Filters |

Grounding Technique | Basic Grounding | Industrial Grounding | Military-grade Grounding | Marine-grade Grounding | Medical-grade Grounding |

EMI Coating | Not Commonly Used | EMI Coatings | Advanced EMI Coatings | Corrosion-resistant EMI Coatings | Biocompatible EMI Coatings |

Regulatory Standards | FCC Part 15 | IEC 61000 series | MIL-STD | IEC 60945 | FDA EMC Guidelines, MDD |

Frequency Range (MHz) | 30 – 300 | 10 – 1000 | 1 – 2000 | 10 – 500 | 0.1 – 1000 |

Signal Processing Algorithms | Basic Noise Filtering | Advanced Noise Filtering | Secure Signal Processing | Advanced Signal Processing | Medical-grade Signal Processing |

Cable Type | Shielded Copper Cables | Industrial-grade Shielded Cables | Military-grade Shielded Cables | Marine-grade Shielded Cables | Medical-grade Shielded Cables |

Encryption/Frequency Hopping | Not Required | Optional | Required | Optional | Optional but Recommended |

Note: The values and types mentioned are typical but can vary based on specific requirements and advancements in technology. Always consult the relevant standards and guidelines for the most accurate and up-to-date information.

Riverdi Product Catalog Overview

Riverdi offers a diverse range of display products suitable for various applications, including LVDS Displays series. Our product line includes:

- STM32 Embedded Displays: These are displays integrated with STM32 microcontrollers.

- RGB, LVDS, MIPI DSI LCD Displays: These are high-quality LCD displays with various interface options.

- EVE Intelligent Displays: These displays are designed for intelligent applications and come with advanced features.

- HDMI Displays: These are displays that can be connected via HDMI.

- E-Paper Modules: These are energy-efficient displays that mimic the appearance of ink on paper.

- Evaluation Boards: These are boards designed for testing and development.

- Accessories: Additional components and tools for display technologies.

Riverdi also offers customization options to fit your specific needs, using high-quality materials and components. They aim to provide an easy and efficient way for you to create your applications and are compatible with various third-party development tools.

Thought-Provoking Questions and Insights

- Customization Capabilities: How can Riverdi’s customization options be leveraged for specialized applications in different sectors like home appliances, industrial devices, and medical equipment?

- Compatibility with Third-Party Tools: What are the implications of Riverdi’s open approach to third-party development tools? How does this affect the ease of integration and development?

- Diverse Product Range: Given the variety of display technologies Riverdi offers, what are the best practices for mitigating EMI across these different types of displays?

Mitigating Electromagnetic Interference with Riverdi Displays

Home Appliance Devices

- Recommended Riverdi Products: STM32 Embedded Displays, RGB LCD Displays

- Key Mitigation Strategies:

- Use of Riverdi’s high-quality shielded cables

- Customization options for EMI coatings

- Compatibility with Third-Party Tools: Riverdi’s open approach allows for easy integration with home automation systems.

Industrial Devices

- Recommended Riverdi Products: EVE Intelligent Displays, LVDS LCD Displays

- Key Mitigation Strategies:

- Riverdi’s industrial-grade Faraday cages

- Advanced noise filtering algorithms

- Regulatory Standards: Riverdi products are designed to meet IEC 61000 series standards.

Military Applications

- Recommended Riverdi Products: HDMI Displays with advanced encryption options

- Key Mitigation Strategies:

- Customizable military-grade shielding materials

- Frequency hopping and encryption features

- Regulatory Standards: Compatibility with MIL-STD for EMI.

Marine Environments

- Recommended Riverdi Products: E-Paper Modules for energy efficiency, RGB LCD Displays for high visibility

- Key Mitigation Strategies:

- Corrosion-resistant, conductive enclosures

- Customizable advanced signal processing algorithms

- Unique Challenges: Riverdi’s marine-grade products are designed to withstand saltwater and electrically noisy environments.

Medical Devices

- Recommended Riverdi Products: STM32 Embedded Displays for integrated solutions, EVE Intelligent Displays for advanced applications

- Key Mitigation Strategies:

- Medical-grade shielding materials

- Customizable low-EMI components

- Regulatory Standards: Designed to meet FDA EMC Guidelines and MDD in Europe.

Riverdi’s diverse range of display technologies offers a plethora of options for mitigating electromagnetic interference across various sectors. Their customization options and compatibility with third-party tools make them a versatile choice for any application. By selecting the appropriate Riverdi product and employing sector-specific mitigation strategies, one can effectively manage EMI while benefiting from high-quality, reliable displays.

Proper EMI Remediation Process

Effectively troubleshooting and mitigating EMI issues in displays involves following best practices:

- Identify the symptoms and problems caused by EMI. Reproduce if possible.

- Detect sources of interference using EMI meters and spectrum analyzers.

- Characterize coupling paths through cabling, ground planes, enclosure openings, etc.

- Determine display susceptibility factors frequency range, impedances, component sensitivities.

- Evaluate potential mitigation solutions using EMI modeling software if needed.

- Apply fixes starting with the lowest cost methods like separation and grounding.

- Verify EMI reductions with field strength meters and system functionality checks.

- Perform thorough EMI testing like radiated emissions, susceptibility, harmonics measurement.

- Follow rigorous EMC compliance standards testing before product release.

Recommendations for Electronic Engineers Designing LCD Displays with EMI Mitigation

Understand the Environment

- Home Appliances: For consumer-grade products, focus on cost-effectiveness while meeting basic EMI standards like FCC Part 15.

- Industrial Devices: Prioritize robustness and durability, adhering to industrial EMI standards like the IEC 61000 series.

- Military Applications: Ensure that the design meets stringent military standards (MIL-STD) for EMI.

- Marine Environments: Consider corrosion-resistant materials and designs that can withstand electrically noisy environments.

- Medical Devices: Adhere to FDA EMC Guidelines or the Medical Device Directive (MDD) in Europe.

Choose the Right Display Technology

- Riverdi’s STM32 Embedded Displays: Ideal for integrated solutions in home appliances and medical devices.

- Riverdi’s EVE Intelligent Displays: Suitable for industrial and advanced medical applications requiring intelligent features.

Shielding and Grounding

- Use High-Quality Shielding Material: Consider materials like aluminum foil for home appliances, Faraday cages for industrial settings, and mu-metal for military applications.

- Proper Grounding: Ensure that all components are properly grounded to reduce EMI.

Filtering and Signal Processing

- Low-Pass Filters: Ideal for home appliances and general-purpose industrial devices.

- Advanced Signal Processing Algorithms: Consider using these for military and marine environments where the signal-to-noise ratio is critical.

Component Selection and Layout

- Use Low-EMI Components: Especially critical for medical devices.

- Strategic Component Placement: Place components in a manner that minimizes the paths for EMI.

Software Solutions

- Frequency Hopping: Useful in military applications to mitigate the effects of EMI and prevent jamming.

- Noise Filtering Algorithms: Can be used in industrial and medical devices to filter out EMI.

Regulatory Compliance and Testing

- Pre-Compliance Testing: Conduct this to identify any potential issues before they become a problem.

- Certification: Ensure that the final product is certified according to the relevant EMI standards for its intended application.

Leverage Customization Options

- Riverdi’s Customization: Utilize Riverdi’s customization options to tailor the display technology according to the specific needs of your application.

Documentation and Record-Keeping

- Maintain Comprehensive Documentation: Keep records of all tests, component selections, and design rationales for future reference and for compliance purposes.

By following these recommendations, electronic engineers can design LCD displays that are not only high-performing but also resilient against electromagnetic interference across various applications.

Advice for Designers of Home Appliances and Industrial Devices on Mitigating Electromagnetic Interference (EMI)

For Home Appliance Designers

- Understand EMI Standards: Familiarize yourself with consumer-grade EMI standards like FCC Part 15 in the United States. Your product must comply with these regulations.

- Choose Appropriate Display Technology: Opt for displays like Riverdi’s STM32 Embedded Displays that offer a balance between performance and cost.

- Use Low-Pass Filters: These are effective for most home appliances in filtering out high-frequency noise.

- Shielding: Consider using aluminum foil or similar cost-effective shielding materials around sensitive components.

- Grounding: Ensure proper grounding of all electrical components to minimize EMI.

- Cable Management: Use shielded cables for internal wiring and keep cable lengths as short as possible to reduce EMI.

- Pre-Compliance Testing: Conduct EMI tests in the design phase to identify and rectify issues early on.

- User Interface: Consider implementing software algorithms to filter out EMI-induced noise in touch-sensitive displays.

- Component Quality: While cost is a factor, do not compromise on the quality of components, as poor-quality components can be significant sources of EMI.

For Industrial Device Designers

- Adhere to Industrial Standards: Make sure your design complies with industrial EMI standards like the IEC 61000 series.

- Robust Shielding: Use industrial-grade Faraday cages or EMI coatings to shield sensitive components.

- Advanced Filtering: Employ advanced noise filtering algorithms and possibly band-pass filters to allow only the necessary frequencies.

- Grounding: Use industrial-grade grounding techniques to ensure that all components are properly grounded.

- High-Quality Cables: Opt for industrial-grade shielded cables to minimize conducted EMI.

- Customization: Leverage customization options like those offered by Riverdi to tailor the display technology to your specific industrial needs.

- Redundancy: In critical systems, consider implementing redundant circuits to mitigate the effects of EMI.

- Software Solutions: Use advanced signal processing algorithms to distinguish between legitimate signals and noise.

- Regular Testing: Conduct regular EMI tests to ensure that the system remains compliant and to identify any new sources of EMI.

- Documentation: Keep meticulous records of all EMI mitigation measures, tests, and component selections for compliance and future reference.

By adhering to these guidelines, designers in both the home appliance and industrial sectors can effectively mitigate the challenges posed by EMI, ensuring that their products are both reliable and compliant with relevant standards.

Maintaining Display Reliability and Image Quality

As electronics advance and become more complex, effective EMI management is imperative to prevent interference issues with display systems across industrial, commercial, aerospace, automotive, and consumer product sectors.

By understanding EMI mechanisms, implementing shielding, filtering, grounding, and sound circuit design, and performing comprehensive testing, manufacturers can ensure displays perform reliably without disrupted imagery, flickering, and other problems caused by electromagnetic disturbances.

Proactively addressing EMI concerns early in the design process with requirements planning, hardening, and materials selection is far more effective than trying to fix issues later after integration and testing. With diligent EMI prevention and mitigation measures, companies can deliver high quality displays with stellar visual performance even in challenging electrical environments with substantial electromagnetic interference.

Summary: Mitigating EMI in Home Appliances and Industrial Devices

Key Points for Home Appliance Designers:

- Standards & Compliance: Familiarize yourself with consumer EMI standards like FCC Part 15.

- Display Choice: Opt for cost-effective yet reliable displays like Riverdi’s STM32 Embedded Displays.

- Basic Shielding & Filtering: Use aluminum foil for shielding and low-pass filters for noise reduction.

- Grounding & Cabling: Ensure proper grounding and use shielded cables for internal wiring.

- Quality Over Cost: Don’t compromise on component quality as it can be a significant source of EMI.

Key Points for Industrial Device Designers:

- Industrial Standards: Adhere to industrial EMI standards such as the IEC 61000 series.

- Robust Shielding: Use industrial-grade Faraday cages or EMI coatings.

- Advanced Filtering: Employ noise filtering algorithms and possibly band-pass filters.

- Grounding & High-Quality Cables: Use industrial-grade grounding and shielded cables.

- Customization & Redundancy: Leverage customization options and implement redundant circuits for critical systems.

General Advice for Both:

- Pre-Compliance Testing: Conduct EMI tests early in the design phase.

- Software Solutions: Implement algorithms to filter out EMI-induced noise.

- Documentation: Keep detailed records for compliance and future reference.

By adhering to these guidelines and recommendations, designers in both home appliances and industrial sectors can effectively mitigate EMI, ensuring their products are reliable and compliant with relevant standards.

FAQ: Mitigating Electromagnetic Interference in Display Technologies

General Questions

- What is Electromagnetic Interference (EMI)?

- EMI is a disturbance generated by external sources that affects an electrical circuit through electromagnetic induction, electrostatic coupling, or conduction.

- Why is EMI mitigation important in display technologies?

- EMI can distort visual output, reduce the lifespan of the display, and compromise the integrity of other connected systems.

- What are the common sources of EMI?

- EMI can come from external sources like other electronic devices, power lines, and natural phenomena, as well as internal sources within the device itself.

Sector-Specific Questions

- How does EMI affect home appliances?

- EMI can cause malfunctions in smart refrigerators, ovens, and washing machines, leading to incorrect readings or unresponsive touch panels.

- What about industrial devices?

- In industrial settings, EMI can affect the reliability of control panels and monitoring systems, which are critical for operations.

- Are there special considerations for military, marine, and medical devices?

- Yes, these sectors have stringent EMI standards and require advanced mitigation strategies due to the critical nature of their applications.

Product-Specific Questions

- What types of displays does Riverdi offer?

- Riverdi offers a range of displays including STM32 Embedded Displays, RGB, LVDS, MIPI DSI LCD Displays, EVE Intelligent Displays, HDMI Displays, E-Paper Modules, and more.

- How can Riverdi displays be customized for EMI mitigation?

- Riverdi offers customization options that allow you to tailor the display technology according to the specific needs of your application, including EMI mitigation.

Design Recommendations

- What are some key EMI mitigation strategies for home appliance designers?

- Key strategies include understanding EMI standards, choosing appropriate display technology, using low-pass filters, and ensuring proper grounding.

- What should industrial device designers focus on?

- Focus on robust shielding, advanced noise filtering algorithms, industrial-grade grounding, and high-quality cables.

- Any general advice for designers in both sectors?

- Conduct pre-compliance testing, implement software solutions for noise filtering, and keep detailed records for compliance and future reference.

By referring to this FAQ, designers and engineers can get a quick overview of the critical aspects of EMI mitigation in display technologies across various sectors.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!