Remember those devices with touch screens where you had to actually press it to get a response? Like really press your finger hard onto the screen? Especially when it was no longer new, the pressure had to be greater each time until you just hit it with your fingers and maybe finally got a result, not necessarily the one you were hoping for…

The remnants of this technology are also very visible when older touch screen users get a modern mobile or a tablet and try to press it instead of touching it lightly. I don’t know how many times I had to shout: “Dad! Not so hard! Just touch it! Don’t press!” This is because the older generation is so used to buttons, those visible and those hidden under the resistive touch tech that was so revolutionary in the 70s.

It is often the case that technology is first developed for the likes of military, medical or other large and important industries, and so all those users got used to the resistive touch screens that had to be pressed. When capacitive technology was developed, it was meant for the commercial market of delicate fingers touching tablets and mobiles and they were never suitable for those harsher environments where water was present and where people wore gloves. Here is a behind the scenes for capacitive and resistive technology.

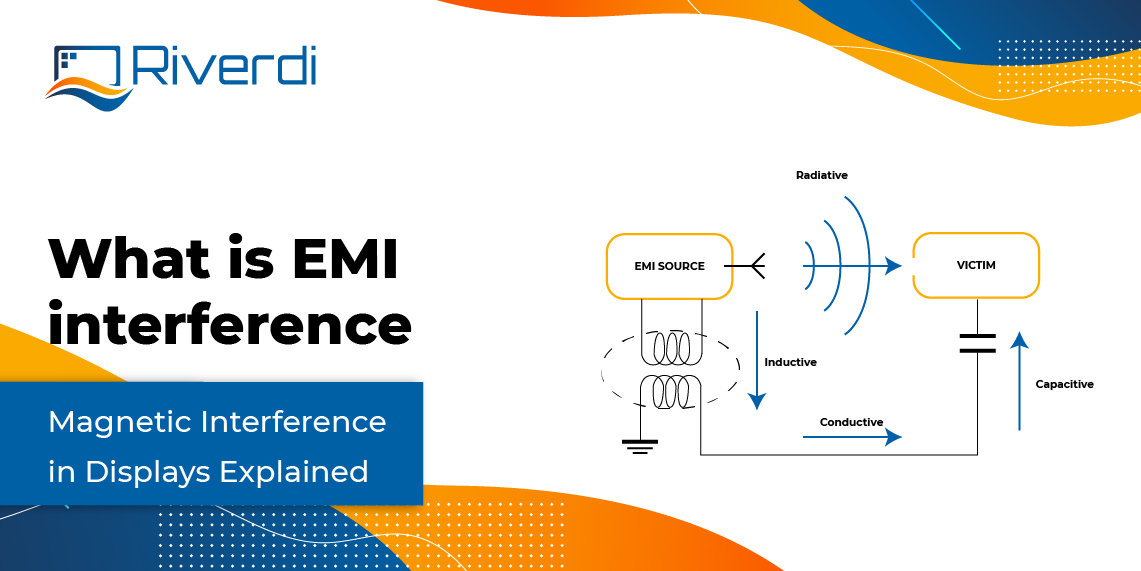

And while this is now long in the past, many people still wrongly associate resistive panels with better performance in industrial applications while capacitive only with the consumer market of gadgets. Electromagnetic Compatibility has always been in the top reasons why resistive touch panels used to be better – a very important feature in those previously mentioned markets.

However, the touch panel technology has evolved so much in the recent years, resistive touch panels hardly ever are a better choice and the only advantage one could argue they have is their price – they are cheaper. But that’s it. The projected capacitive panels of today are far superior; they are so advanced they can not only work with water, thick gloves, multi-touch, or severe electromagnetic interference but they also bring all the advantages of being very durable, small, light and just commercially pretty.

They can also be customized to virtually any specifications. Give it a try!

Here is more technical info on why our Projected Capacitive Touch Panels will work with virtually any project you might have.