- Zero time-to-market with pre-programmed display

- Ready-to-use libraries and simplified workflow

- Engineering effort proven on the market

- Pre-certification for undisturbed focus on your application

- Designed for versatility—applied across industries

- From off-the-shelf to application-specific design

- Hardware-level customization available

- No limits to own the design

- Deep customization with ST’s native tools

- Key features of Riverdi’s most advanced display

- Zero barriers for an immediate start

- About schematics and system transparency

- Not sure yet? Riverdi’s team is here to help

PART 2.

Accelerating time-to-market, customization and engineering freedom

In this follow-up article, we focus on how Riverdi’s STM32 Embedded Displays TFT family helps development teams reduce design effort, speed up prototyping, and scale into mass production with confidence. Based on real-world use cases and insights from Riverdi’s engineering team, you’ll learn how these all-in-one display modules streamline both technical implementation and product delivery.

Topics covered:

- How preconfigured hardware and TouchGFX support accelerate development

- What industries are using STM32 displays—and why they are a perfect match

- Adjusting display hardware for specific applications and production volumes

- Full access to STM32CubeMX, CubeIDE, and TouchGFX for advanced control

- What to expect from Riverdi’s support, documentation, and customization services

Want to get the introduction to STM32 family, know its interface and expansion capabilities or how to drive two displays using a single system? Read part 1 of this article.

Zero time-to-market with pre-programmed display

One of the core advantages of Riverdi’s STM32 Embedded Displays is the complete reduction in time-to-market. These modules are shipped fully operational—preloaded with a working demo and pre-integrated with ST’s TouchGFX environment. Developers can select the LCD display from the available hardware targets, open TouchGFX, and immediately begin working on their own interface. A single click transfers the UI to the hardware, and the display runs the application without any additional setup.

This plug-and-play readiness eliminates the time-consuming hardware configuration phase. Instead of setting up and validating multiple components, engineers can start building their application logic and interface right away.

Ready-to-use libraries and simplified workflow

In addition to the out-of-the-box compatibility with TouchGFX, Riverdi provides a complete set of predefined libraries tailored for STM32-based displays. These resources significantly reduce the effort required for display programming, peripheral management, and UI rendering—freeing developers to focus on their core application.

As a result, valuable engineering hours are no longer spent on:

- configuring signal routing,

- writing low-level drivers,

- debugging hardware integration issues.

This is particularly beneficial from the R&D teams’ point of view, where every hour of development counts.

Engineering effort proven on the market

STM32 displays are already used in a plenty of commercial applications—from their prototyping to full-scale production stages. According to Riverdi’s customer feedback, the integration of processing, memory, and display in one unit has enabled them to build devices they previously considered too complex: large-format screens, high-resolution HMIs, and sophisticated interfaces—all without the need for huge amounts of time or proficient engineers.

In traditional embedded development, designing such systems from the start would involve mastering multi-layer PCB design, managing high-speed signal integrity (e.g., LVDS, memory bus), and implementing low-level firmware to ensure proper communication. Riverdi has done this heavy lifting in advance—so that STM32 users don’t have to.

Pre-certification for undisturbed focus on your application

Each STM32 Embedded Display is built not only for performance, but also for safety in a sense of regulations. Riverdi conducts pre-certification testing for electromagnetic compatibility (EMC) in specialized chambers. The hardware is optimized to minimize interference, ensuring passing the certification later on.

Keeping simplicity at its peak, engineers receive a display that is:

- Fully functional out of the box

- Electrically and mechanically verified

- Tested for EMC compliance

- Proven on the market across multiple models

All of this translates into reduced development cost, shorter time-to-certification, and faster delivery of finished products—while allowing engineering teams to focus entirely on their application.

Designed for versatility—applied across industries

Riverdi’s STM32 Embedded Displays have seen widespread adoption across a diverse range of industries. Current use cases include:

- Medical devices meeting rigorous safety and performance standards with Electrostatic Discharge (ESD) protection and electromagnetic compatibility

- EV charging stations requiring real-time responsiveness and powerful high-brightness outdoor performance

- Parcel terminals and lockers with connected HMIs

- Smart home systems for controlling lighting, heating, or security

From off-the-shelf to application-specific design

While the standard display modules are powerful and feature-rich, many industrial customers use only a portion of the board’s capabilities in their final design. That’s why Riverdi offers customization services for scaling up production.

Once the initial design is validated, and the project moves toward volume manufacturing (at least hundreds or thousands of units), Riverdi can help optimize the STM32 hardware by removing unused components — reducing both complexity and cost.

For example:

- If the product doesn’t require CAN interfaces, they can be removed, if only Modbus is needed

- Ethernet connection can be omitted if networking is handled elsewhere.

- Memory size can be scaled—either up, or down—based on actual application needs.

Since memory is one of the more cost-sensitive elements of the BOM, adjusting its size to match the system requirements is a common way to reduce per-unit cost in large-scale production.

Hardware-level customization available

Beyond component optimization, Riverdi also supports custom board-level modifications to meet specific industry or mechanical requirements.

For instance, one of Riverdi’s automotive clients required a different connector standard than the default industrial-grade Molex. Riverdi was able to replace the connectors with automotive-specific ones—ensuring compatibility without the customer having to redesign their enclosure or cabling.

This ability to adapt the hardware for demanding markets and standards—including medical, automotive, and smart infrastructure—makes STM32 Embedded Displays a reliable long-term platform, not just a prototyping tool.

To explore customization options, engineers can simply visit riverdi.com and fill out the contact form—the Riverdi team will provide guidance based on project goals, target volume, and required feature set.

No limits to own the design

A common limitation found in many smart display modules is their closed architecture. Manufacturers often restrict access to the hardware and software completely or to a large extent. While this simplifies basic integration, it severely limits flexibility for more advanced use cases.

Riverdi’s STM32 Embedded Displays were designed with a fundamentally different philosophy: maximum openness and developer control.

The displays ship with fully working demos and preconfigured TouchGFX projects, but the system is entirely accessible. Developers can go far beyond GUI design and treat the STM32-based display like their own embedded board.

Deep customization with ST’s native tools

Engineers familiar with ST’s development ecosystem can take advantage of:

- TouchGFX—for immediate creation of modern, touch-enabled UIs

- STM32CubeMX—to configure the system

- STM32CubeIDE—to manage and build software directly to the onboard microcontroller

With this toolchain the display behaves just like a standard STM32 development board—allowing engineers to build, modify, and control the system in a purely limitless way. In other words, with Riverdi you not only use the display, but also own the system.

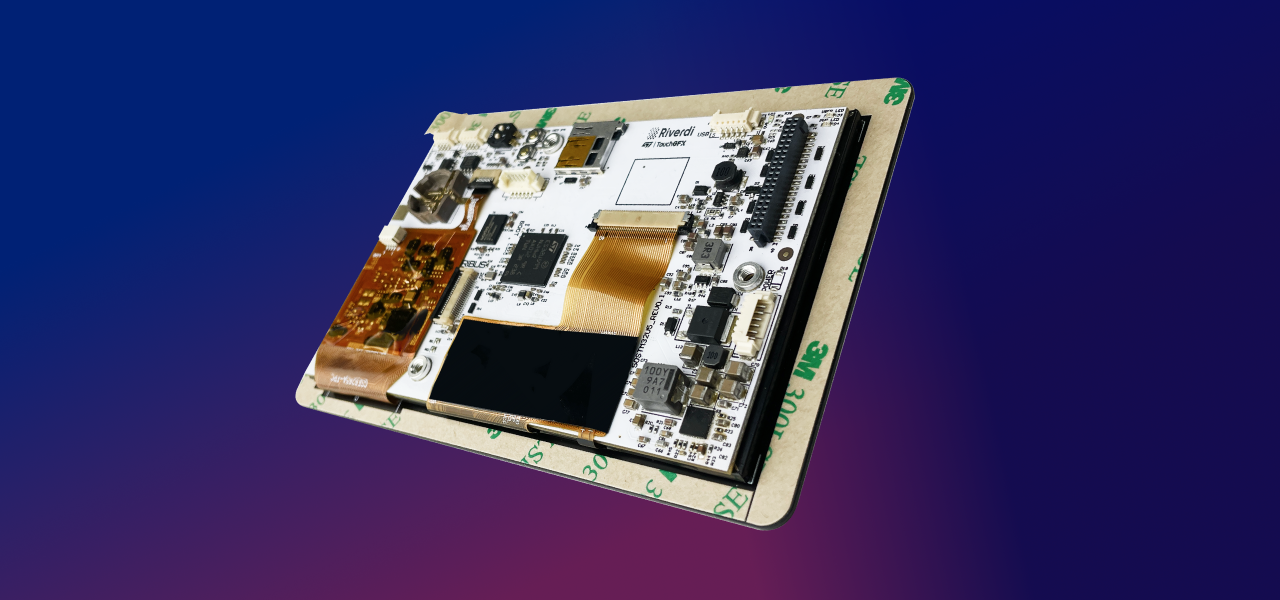

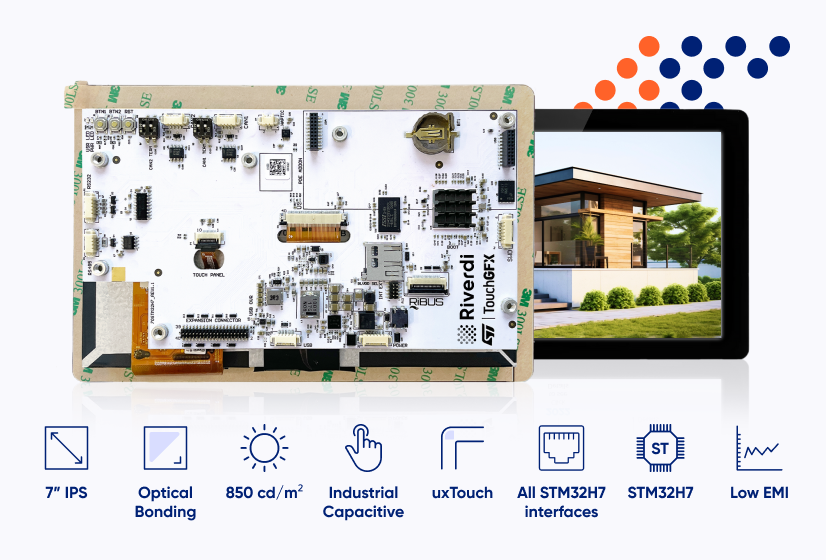

Key features of Riverdi’s most advanced display

The STM32 Embedded Display series represents one of Riverdi’s flagship solutions—designed to simplify embedded system development by integrating processing, memory, and interfaces directly into the display module. The core advantage lies in its truly all-in-one architecture: developers no longer need to design a separate embedded system to drive the display. Instead, the display itself becomes the heart of the device.

While a wide range of features are available — including industrial interfaces, dual-display support, haptic feedback, and modular expansion — the most important benefit is eliminating the need for low-level system design. The display is pre-engineered, pre-tested, and production-ready.

Zero barriers for an immediate start

To begin working with the STM32 Embedded Display series, engineers can simply visit riverdi.com, select the appropriate display size, mounting style, and touch configuration (or non-touch variant), and order directly.

Once received, the display is ready to use out of the box. It can be integrated with TouchGFX immediately, without any additional configuration. Riverdi provides a full suite of supporting materials—including quick-start guides, documentation, and answers to frequently asked questions—making the onboarding process smooth even for non-engineers.

About schematics and system transparency

While Riverdi does not publish full electrical schematics of the STM32 Embedded Display boards, developers are given access to detailed block diagrams via the knowledge base and support sections on the website. These diagrams include:

- Pin mapping and signal assignments

- Interface routing

- Port availability and configuration

Additionally, all relevant configurations are accessible through STM32CubeMX, allowing full visibility into system architecture so that the hardware remains engineer-friendly and easy to develop your own application.

Not sure yet? Riverdi’s team is here to help

For those still analyzing whether the STM32 series is suitable for their application, Riverdi encourages direct contact. The team works closely with engineers and project managers on a daily basis to customize solutions, answer technical questions, and assist with product selection.

No matter the scale or the stage of your project—Riverdi’s STM32 Embedded Displays offer a reliable, high-performance foundation for building responsive, modern and modular HMI systems.

CHECK OUT RIVERDI’S IMPLEMENTATION-READY PRODUCTS

Be sure to find the right industrial-grade display for your device:

- Need to enhance the brightness and optical performance of your display? Choose High Brightness IPS Displays with optical bonding that perfectly reduce the reflection and correct contrast.

- In search of the most effective data interchange between graphics and a truly industrial touch controller? Check BT817Q (EVE 4) product category with revolutionary communication protocol for industrial, medical and military applications requiring beautiful and sophisticated GUI.

- Looking for one of the highest resolution (1280×800 pixel) HMI displays based on STM32H7 MCUs? Choose STM32 Embedded Displays with high performance enabled by STM32H757XIH6 (2MB Flash, 1MB RAM) microcontroller.

- Need a plug and play HDMI interface and USB-C touch solution? Pick the HDMI Displays that are high-resolution, high-brightness IPS TFT products with optical bonding and industrial grade touch screen as Riverdi’s standard.

CONTACT US

Contact our expert to dive deeper into display implementation for your project.

Having issues with your current technology? Want to learn about frameworks and our clients’ success stories? We are happy to discuss and assist you with your design and R&D challenges.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!