- Introduction

- Selecting the right interface and platform

- Power supply—key design decisions

- Hardware and software integration

- Prototyping and pre-certification testing

- From prototyping to mass production—cost optimization

- Logistics and supply chain planning

- Common engineering mistakes to avoid

- Recommendation on how to avoid mistakes

- The display represents the device—best practices for engineers

- Recommendation on how to implement best practices

- Riverdi as your implementation partner

- Conclusion

PART 2.

From the display optimization to common pitfalls and best practices

In this article you will explore engineering best practices from interface design to mass production. Learn how to avoid common pitfalls and optimize display performance as well as production costs based on real-world examples.

Topics covered:

- Selecting the optimal interface for your system architecture

- Power supply considerations and power optimization strategies

- Hardware and software integration using Riverdi’s tools and libraries

- Pre-certification testing and prototyping approaches

- Strategies for cost optimization and scalability

- Best practices for supply chain and logistics planning

- Common engineering mistakes in display integration

- Practical recommendations for engineers and system designers

Introduction

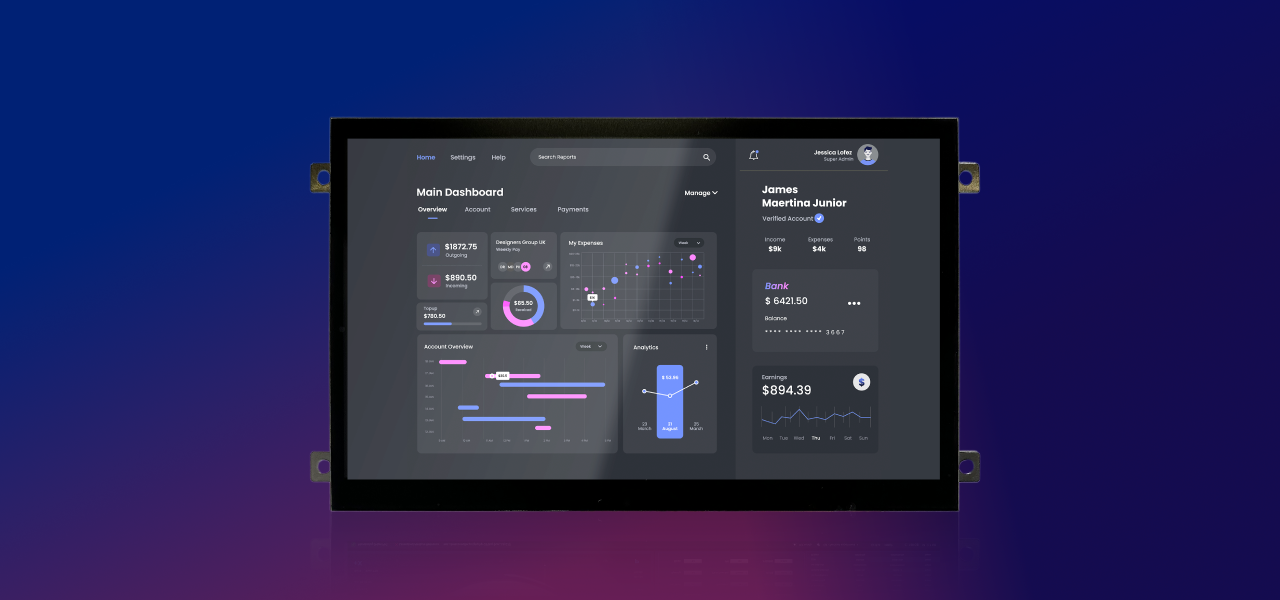

In embedded system design, the display is not just a visual interface — it is the device’s primary interaction point. The first part of the article presented the fundamentals of defining the purpose of a display. The second part focuses on guiding the engineer through the choices in the process related to interface, power, hardware, software, testing and logistics—in a way that reduces not only cost but also time.

Selecting the right interface and platform

Having already established the basics of choosing a specific technology, it is time to move on to interface design. The interface choice should be based on the system architecture. Riverdi supports integration across various embedded platforms, such as:

| Platform Type | Description | Use Case |

| STM32 | Microcontroller-based embedded systems | Low to medium complexity HMI applications |

| i.MX | More powerful ARM-based processors | Advanced graphics, Linux-based GUI |

| EVE4 Intelligent Display | Built-in controller with graphics features | Simplified integration with reduced system overhead |

If unsure about the appropriate interface, Riverdi encourages contacting their team to consult each specific case with experts.

Power supply—key design decisions

Potential power supply limitations significantly affect display performance.

That is why it is worth defining its power source at the beginning of the process—whether it will be, as in most cases, constant as a default mode and connected to the grid or will the power be supplied by batteries.

Thus, two key approaches can be defined:

| Power mode | Characteristics | Design considerations |

| Constant Power | Main grid-powered systems (default) | No specific power optimization needed |

| Battery-powered | Mobile or off-grid devices | Requires careful power consumption planning |

In the case of battery power, we can reduce the power consumption of a number of components. Understanding the use case and operating environment is crucial for power-efficient design. A detailed analysis of various aspects of the display’s application was carried out in Part 1 of the article.

Battery-powered display optimization techniques:

- Lower TFT backlight intensity

- Use power-saving modes (e.g., disabling display while keeping touchscreen active)

- Adjust design to application-specific usage patterns

Hardware and software integration

Riverdi supports developers with low-level firmware and software drivers. They can be downloaded for free from Riverdi’s GitHub. This way it is easy and quick to make sure the display will work on your system. These resources will also help with issues like driver integration and proper timings.

| Resource type | Availability | Notes |

| Low-level drivers | Available on GitHub | Ensure proper operation and timing setup |

| TouchGFX | Integrated for STM32 displays | Suitable for embedded GUI development |

| LVGL | Certified and pre-integrated | Lightweight GUI for MCUs |

| Other Libraries | Under development | Future support for additional options |

Moreover, engineers working on Linux or Windows platforms can use widely available GUI libraries with their own programmers and designers teams. However, for embedded GUI applications, Riverdi provides integrated graphic stacks with their displays.

Prototyping and pre-certification testing

Riverdi provides the display’s rapid prototyping and certification readiness—especially important for devices such as medical but also for any other machines exposed to demanding operating conditions.

In this regard, Riverdi solutions provide confidence in the most challenging projects by:

- Pretesting:

All Riverdi’s standard displays are environmentally tested in terms of:

- Temperature

- Moisture/Humidity

- Operational reliability

- Electromagnetic emission and immunity

- Documentation

Test reports are typically available on Riverdi’s website. If not, they are available upon request. - Prototyping tools:

- HDMI Displays:

Recommended for purchase as a first type due to the possibility of plug-and-play connection to any PC and performing initial tests - Add-on boards and Evaluation kits:

Enable fast setup of embedded displays and immediate performance testing - Standard products:

Ideal starting point for proof-of-concept

- HDMI Displays:

By simplifying performance evaluation, these tools make standard displays not only ideal for starting a project and prototyping but they also accelerate the product’s time-to-market.

From prototyping to mass production—cost optimization

Riverdi offers customization and cost reduction strategies for mass production scenarios. Such a process often starts with the customer already choosing one of the standard Riverdi products, such as EVE4 Intelligent Display or STM32. These devices are equipped with almost all possible assets and solutions. Since Riverdi allows customization of standard products, the customer can eliminate unnecessary display elements from the PCB board when moving to mass production.

| Optimization area | Description | Result |

| Remove unused interfaces | E.g., serial ports or touchscreen options not required | Lower BOM cost |

| Reduce memory components | Tailored to actual application requirements | Reduced material cost |

| Eliminate connectors | If unused, can be removed from PCB design | Simplified design and assembly |

Once switching from prototype to mass production volumes (1,000+ units), it’s recommended to revisit design requirements with the support of Riverdi experts to fine-tune the display and reduce its costs without compromising quality.

Logistics and supply chain planning

Riverdi’s customer-centric logistics model ensures high flexibility and on-time delivery. The company has many direct clients on annual and longer contracts, which confirms how comprehensively Riverdi supports them in logistics.

From the customers’ point of view, the most helpful solutions are:

- Delivery flexibility:

Order in large quantities (e.g., 1000 or 10,000 displays) or receive in small volumes (e.g., 100 or 1000 units/month). These ranges can be established with the Riverdi team every three months. - Price locking & Stock security:

Riverdi pre-purchases, manufactures and stocks material inventory for long-term contracts for free so that the customer can receive displays on demand, exactly when they need them. - Warehouse location:

Company’s own European stock and co-located factory allows fast, efficient shipments, provides huge stock of materials and enables production planning in advance.

- On-Time Delivery rate:

Since every Riverdi process is measured, the company’s on-time delivery rate is 97–98%, which is considered very high in a volatile display component market.

All in all, this model is designed to support long-term projects with predictable pricing and stable supply chains.

Common engineering mistakes to avoid

From Riverdi’s real-world observations, one of the most frequent and costly mistakes engineers make is underestimating the importance of the display in the early design phase. In many cases, development teams begin with a general idea for a device — for example, a vending machine or a cosmetic tool — and immediately purchase a random display from the market just to start prototyping.

At this stage, the focus is typically placed on system functionality and controller development, while the display is treated as a temporary component that can be replaced later. Unfortunately, this often leads to major setbacks when the project progresses toward mass production.

Here is a summary of the most common technical mistakes in display integration:

| Mistake | Description | Consequences |

| Choosing a random display at the beginning | Purchasing the cheapest available display without considering specifications, documentation or application fit | May lead to costly redesigns, certification issues, or unsuitability for the target environment (e.g., insufficient brightness for outdoor use) |

| Ignoring the display in system design | Focusing on the operation of the device itself while neglecting early integration of the display | Results in mechanical and firmware redesigns, changes to connectors and compatibility issues |

| Using poorly documented displays | Selecting touchscreens with no available drivers, firmware or software examples | Time loss, lack of support, potential failure to integrate |

| Attempting complex display integration without experience | Designing custom display controllers (e.g., STM32 boards) from scratch | Leads to delays, wasted resources and unresolved technical issues |

It is important to emphasize that these mistakes are often driven by overconfidence in future integration. Engineers arbitrarily buy a low-cost display assuming that the final choice can be made late—after a working prototype is built. However, embedded systems are tightly integrated architectures, and changing the display at a later stage may require a complete redesign of connectors, firmware, PCB layout, or mechanical components.

To sum up in short, typical issues caused by initial poor selection include:

- Insufficient brightness for outdoor applications,

- Use of consumer-grade touch controllers that cannot handle thicker cover glass or gloves,

- Inability to pass product certifications, such as for medical devices,

- Redesigning the display for mass production ultimately turns out to be too extensive and expensive.

Another common pitfall is choosing a display that cannot be run at all—often due to a lack of software support. This leads to engineers spending weeks on trial-and-error debugging, eventually reaching out to Riverdi for support—only to discover that the other manufacturer’s display is not supported and no assistance can be offered.

There are also real-world examples of teams spending months developing custom STM32-based display controller boards, struggling with driver layers and graphics stacks—even though fully integrated, production-ready solutions are available from Riverdi.

Recommendation on how to avoid mistakes

Rather than wasting valuable time and engineering resources on uncertain display integration, it is far more efficient to work with a trusted display manufacturer from the start. Choosing a well-documented display — with complete firmware, hardware examples, and technical support — will accelerate development, reduce risk, and ensure a smooth transition to production.

The display represents the device—best practices for engineers

When developing an embedded device, many engineers and system integrators naturally concentrate on the core system functionality—processor selection, control logic, connectivity or power management. Displays are often treated as secondary and their role in the design is postponed until later stages. This approach can lead to fundamental design and operational issues, as the user’s perception of the device is shaped primarily through the touchscreen reliability and sensitivity.

A well-optimized internal process or hardware design may be undermined by a poorly performing display interface. If the touchscreen lags, the image is dim or the interface fails intermittently, the device is judged as unreliable—even if everything else works perfectly.

An example here would be the design of a coffee machine. The internal brewing process may be technically excellent. But if the display fails to communicate clearly, responds poorly to touch or does not function outdoors due to low brightness, the machine will be perceived as low quality.

Recommendation on how to implement best practices

To avoid this disconnect between system performance and user experience, engineers should follow a set of best practices that place the display at the center of the user interface strategy:

| Best Practice | Description |

| Engage display experts early | Start integration with professional consultation to ensure compatibility and long-term design stability. |

| Use well-documented components | Choose displays that come with full documentation, firmware, and software support to accelerate development. |

| Design for user experience | Ensure high brightness, accurate touch response, and vivid color rendering—all of which shape the user’s perception of product quality. |

| Select modular evaluation kits | Use Riverdi add-on boards and evaluation accessories to simplify prototyping and reduce integration time. |

| Secure logistics and pricing | Work with Riverdi to lock in pricing and schedule deliveries, minimizing supply chain disruptions and cost variability. |

Riverdi as your implementation partner

Beyond providing display hardware, Riverdi offers expertise and support throughout the decision-making and implementation process:

- Technical consultation:

engineering guidance on optimal display solutions for specific applications - Documentation access:

immediate availability of complete technical documentation without registration barriers - Prototyping assistance:

evaluation kits and support for rapid proof-of-concept development - Long-term partnership:

support from initial design through volume production and product lifecycle

This partnership approach ensures that engineering teams can make informed decisions quickly, with confidence that they’re selecting the optimal display technology for both immediate implementation and long-term product success.

Conclusion

Integrating a display is not just a technical task—it is a set of strategic design decisions. With embedded systems becoming more compact and specialized, the display is the user’s primary interaction surface and a defining component of perceived quality.

From interface selection to power optimization, from prototyping to mass production and logistics—each phase requires detailed planning. Riverdi supports engineers not only with high-quality hardware but also with tailored guidance, certified libraries and scalable logistics solutions.

CHECK OUT RIVERDI’S IMPLEMENTATION-READY PRODUCTS

Be sure to find the right industrial-grade display for your device:

- Need to enhance the brightness and optical performance of your display? Choose High Brightness IPS Displays with optical bonding that perfectly reduce the reflection and correct contrast.

- In search of the most effective data interchange between graphics and a truly industrial touch controller? Check BT817Q (EVE 4) product category with revolutionary communication protocol for industrial, medical and military applications requiring beautiful and sophisticated GUI.

- Looking for one of the highest resolution (1280×800 pixel) HMI displays based on STM32H7 MCUs? Choose STM32 Embedded Displays with high performance enabled by STM32H757XIH6 (2MB Flash, 1MB RAM) microcontroller.

- Need a plug and play HDMI interface and USB-C touch solution? Pick the HDMI Displays that are high-resolution, high-brightness IPS TFT products with optical bonding and industrial grade touch screen as Riverdi’s standard.

CONTACT US

Contact our expert to dive deeper into display implementation for your project.

Having issues with your current technology? Want to learn about frameworks and our clients’ success stories? We are happy to discuss and assist you with your design and R&D challenges.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!