Resistive touch panels are known to be very affordable and frequently used in many high-use applications.

This Display 101 article will show you some basics on how resistive touch panels work – the structure details, the technology and how challenging it is to get the information from the touch screen into a microprocessor.

Structure

Let’s start from the structure.

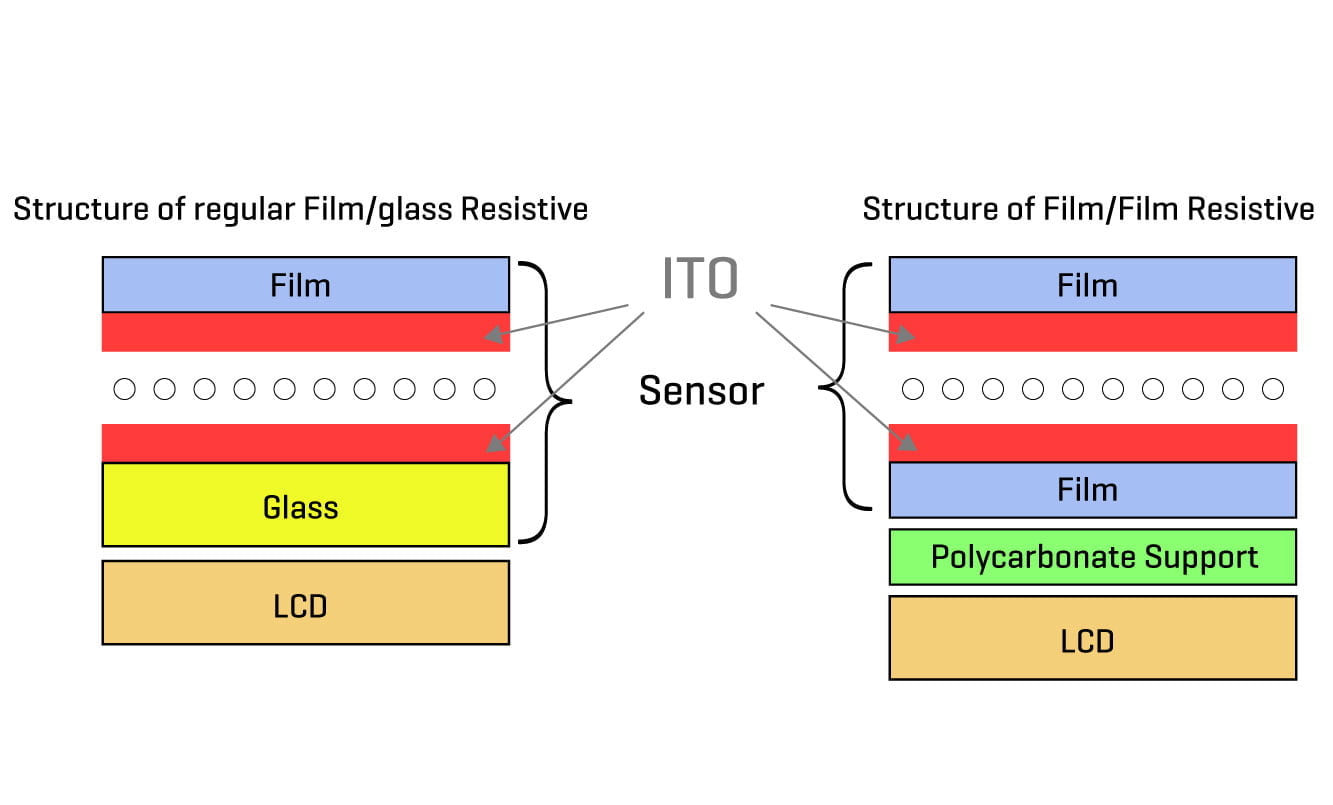

First, there are two kinds of structures for modules with resistive touch panels.

These structures differ based on the support material used:

- glass

- polycarbonate

A more common structure used for resistive touch panels is Film/Glass. The difference is in the material of the bottom layer of the sensor and the accompanying support:

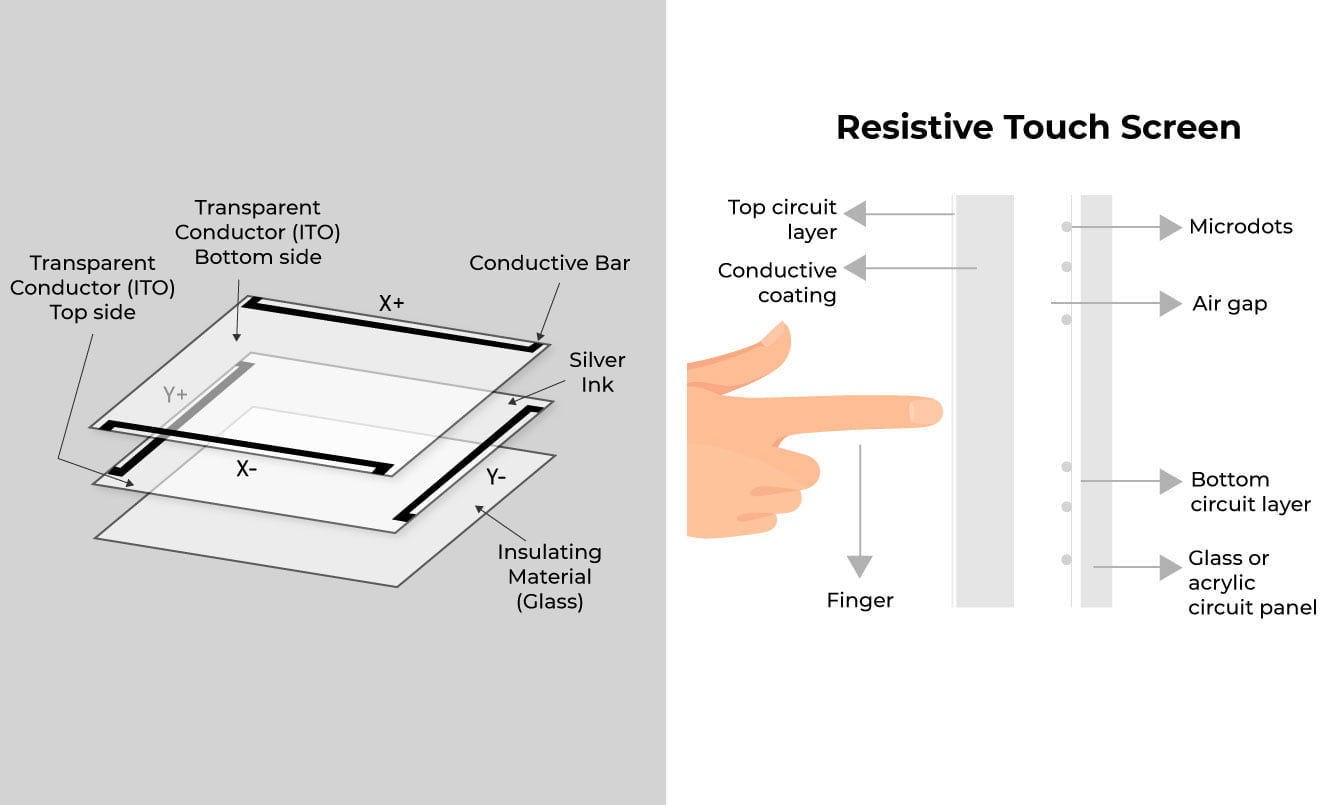

As mentioned, resistive touch sensors are made of glass or acrylic substrate, which are covered with electrically conductive and resistive layers (made of film) covered with ITO (Indium-Tin-Oxide). Those layers are separated by little spacers.

Working principle

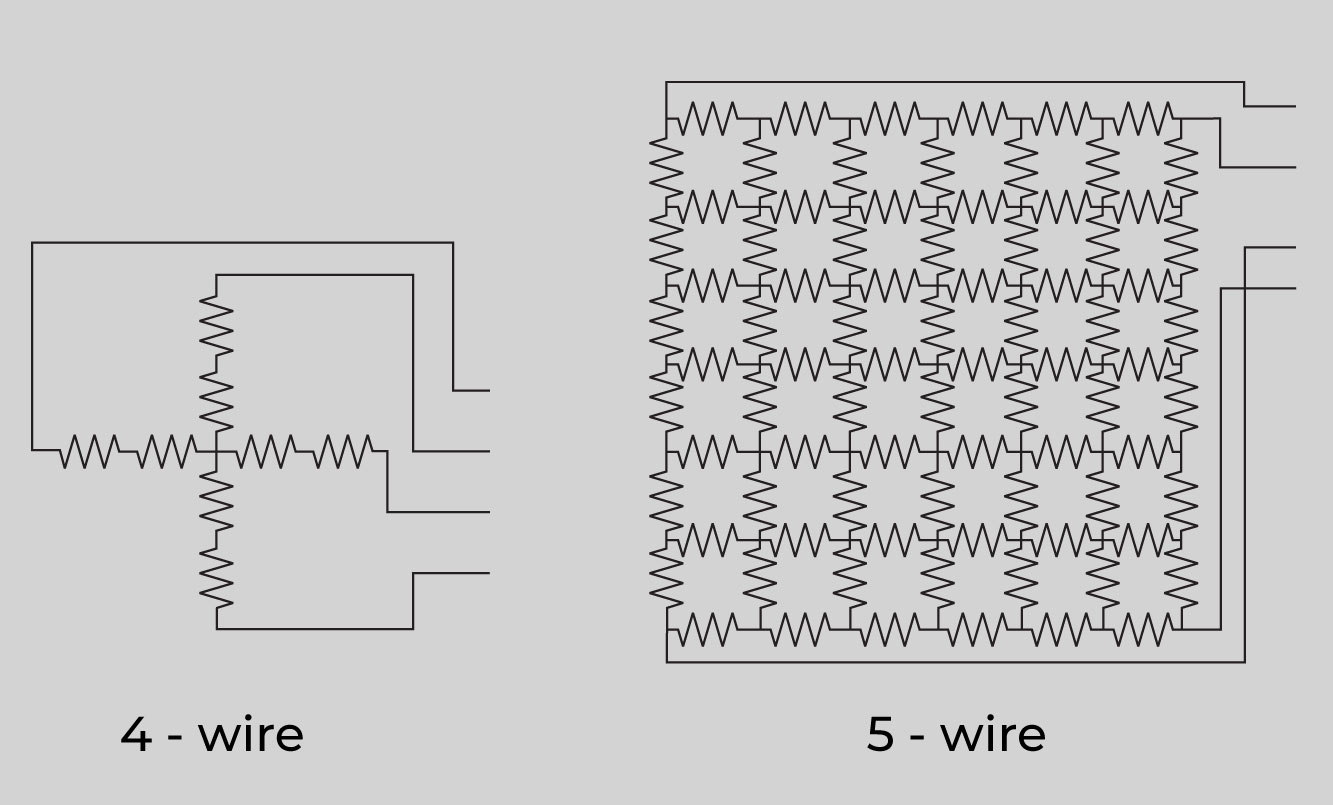

The most popular resistive architectures use 4-wire or 5-wire configurations of the circuit. The drawing below represents the concept schematic of resistive touch:

The circuits determine the location in two coordinate-pair dimensions. As the majority of application are based on 4-wire technology, we will focus on this solution to describe the idea.

So, how is the position measured?

On the touch screen, the voltage is applied in the Y direction. When touching, two layers presses together creating the contact – in this exact position the voltage can be read from one of the X electrodes. At that point the voltage divider is created, so the Y coordinate can be determined.

The procedure then reruns with the X direction being driven – in this case, the voltage value is read from one of the Y electrodes.

Applications

A resistive touch sensor does not depend on the electrical property of capacitance (in contrast to the technology of capacitive touch panels) – sensors sense the pressure on the screen surface. Hence, noise immunity is also higher for resistive touch panels.

Resistive touch technology provides accommodation with non–conducting materials. Thanks to that, a stylus and gloves can be used for modules with resistive touch screens. Resistive touch panels are widely used for the applications planned for harsh environmental conditions.

It is also worth to mention, that resistive technology, unlike as capacitive, supports only “single – touch”.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!