- 1. Understanding the Functionality of ZIF Connectors

- The Role of Zero Insertion Force Technology in Modern Electronics

- 3. Key Benefits of Using ZIF Connectors

- 4. Different Types of ZIF Connectors and Their Applications

- 5. How to Properly Use and Maintain ZIF Connectors

- 6. Future Trends and Developments in ZIF Connector Technology

- Frequently Asked Questions

Welcome to the fascinating world of Zero Insertion Force, or ZIF, connectors! If you’ve ever wondered how your electronic devices manage to function so smoothly, you’re about to embark on a journey that will unravel the mystery. This article will delve into the heart of modern electronics, where ZIF connectors play a pivotal role.

Imagine a world where connections are made effortlessly, without the need for force or pressure. That’s the world of ZIF connectors. We’ll explore the intricate functionality of these connectors, revealing how they’ve revolutionized the electronics industry.

We’ll also delve into the numerous advantages of using ZIF connectors, from their ease of use to their high reliability. But we won’t stop there. We’ll also guide you through the diverse range of ZIF connectors available in the market and their myriad applications.

And for those of you who are hands-on, we’ll provide some practical tips on how to use and maintain these connectors to ensure they continue to perform optimally.

Finally, we’ll gaze into the crystal ball and explore the future trends and developments in ZIF connector technology. So, buckle up and get ready for an electrifying ride into the world of ZIF connectors. This is going to be a journey of discovery that’s as exciting as finding a hidden Easter egg in your favorite video game!

1. Understanding the Functionality of ZIF Connectors

When it comes to the world of electronics, ZIF connectors play a pivotal role in ensuring seamless and efficient connections. These connectors, known for their Zero Insertion Force technology, are designed to allow for the easy insertion and removal of integrated circuits (ICs) without causing any damage. This is particularly beneficial in applications where frequent component swapping is required. The key to their functionality lies in their unique design, which includes a lever or slider that when moved, releases or secures the ICs in place. This not only simplifies the process but also reduces the risk of damaging the pins. Tip: When using ZIF connectors, ensure the lever or slider is in the correct position before inserting or removing an IC to prevent any potential damage.

The Role of Zero Insertion Force Technology in Modern Electronics

In the realm of modern electronics, Zero Insertion Force (ZIF) technology plays a pivotal role. This technology, primarily used in the design of connectors, has revolutionized the way electronic devices are assembled and maintained. ZIF connectors, with their unique design, allow for the smooth and effortless insertion of Integrated Circuit (IC) chips into sockets, eliminating the risk of damage during installation.

One of the key advantages of ZIF connectors is their ability to enhance the longevity of electronic devices. By reducing the mechanical stress exerted on the IC chips during insertion, these connectors minimize wear and tear, thereby extending the lifespan of the devices. Furthermore, the use of ZIF technology simplifies the process of upgrading or replacing components, making it a cost-effective solution for manufacturers and consumers alike.

However, the successful implementation of ZIF technology requires careful consideration of several factors. A checklist for effective use of ZIF connectors might include: ensuring the connector is compatible with the IC chip, verifying the connector is properly aligned before insertion, and confirming the locking mechanism is secure after insertion. By adhering to these guidelines, users can fully leverage the benefits of ZIF technology and contribute to the advancement of modern electronics.

3. Key Benefits of Using ZIF Connectors

One of the primary advantages of using ZIF connectors is their ability to provide a reliable, high-quality connection with minimal wear and tear. This is due to the zero insertion force technology, which eliminates the need for mechanical pressure during the insertion process. As a result, ZIF connectors are less likely to suffer from physical damage, ensuring a longer lifespan and reducing the need for frequent replacements.

Another significant benefit of ZIF connectors is their ease of use. The zero insertion force design allows for quick and easy connection and disconnection, making them ideal for applications that require frequent changes or adjustments. This ease of use also reduces the risk of incorrect insertion, which can lead to connection failures and potential damage to the device. Efficiency, reliability, and user-friendliness are therefore key benefits of using ZIF connectors.

Lastly, ZIF connectors offer a high degree of flexibility and versatility. They are available in a wide range of sizes, configurations, and types, making them suitable for a variety of applications. Whether you need a connector for a small, compact device or a large, complex system, there is likely a ZIF connector that will meet your needs. To ensure you choose the right ZIF connector for your application, consider the following checklist: the size of the connector, the number of contacts, the pitch, the orientation, and the mounting style. Choosing the right ZIF connector can significantly enhance the performance and longevity of your device.

4. Different Types of ZIF Connectors and Their Applications

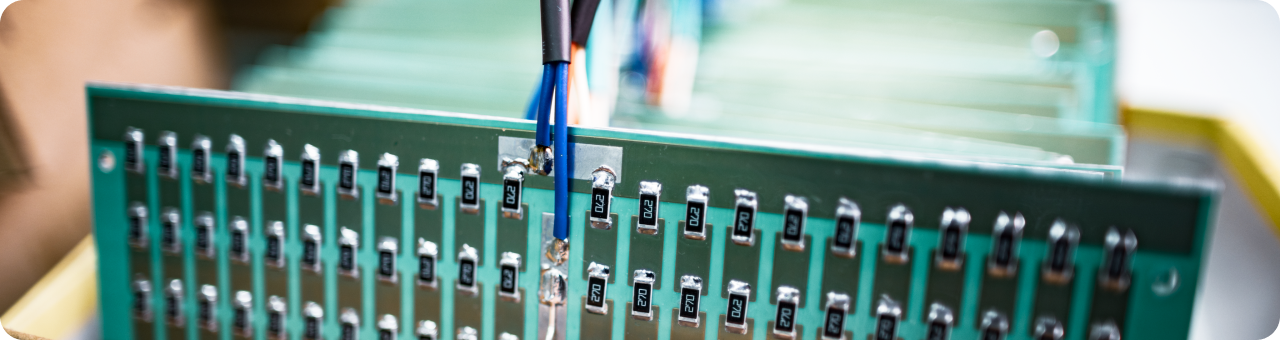

There exists a wide array of ZIF connectors, each designed to cater to specific applications. Flat Flexible Cable (FFC) ZIF connectors are commonly used in digital cameras, laptops, and other compact electronic devices due to their flexibility and small size. They are ideal for tight spaces and allow for easy assembly and disassembly. Another type, the Land Grid Array (LGA) ZIF connectors, are typically found in high-speed applications such as servers and networking equipment. Their design allows for a high number of interconnects while maintaining a small footprint.

Low Profile ZIF connectors are another type that are often used in applications where space is a premium. These connectors are designed to be compact, making them ideal for use in slim devices such as tablets and smartphones. On the other hand, Through-Hole ZIF connectors are often used in applications that require a robust and reliable connection. These connectors are mounted directly onto the PCB, providing a secure and durable connection that can withstand harsh conditions.

It’s important to note that while ZIF connectors have many advantages, they also have their limitations. For instance, they are not suitable for high-voltage applications due to their low contact force. Tip: Always consider the specific requirements of your application when choosing a ZIF connector. This will ensure that you select the most suitable connector that can deliver optimal performance and reliability.

5. How to Properly Use and Maintain ZIF Connectors

Proper usage and maintenance of ZIF connectors are crucial to ensure their longevity and optimal performance. Firstly, always ensure that the connector is fully open before inserting or removing the cable. Forcing the cable in or out can damage both the connector and the cable. Secondly, handle the connector with care. These components are delicate and can easily be damaged by excessive force or mishandling. Regular cleaning is also essential to prevent dust and debris from accumulating and causing connectivity issues. Use a soft, dry cloth to gently wipe the connector and keep it clean. Lastly, when not in use, store your ZIF connectors in a cool, dry place away from direct sunlight and heat sources. Following this simple checklist can significantly extend the lifespan of your ZIF connectors and maintain their performance.

6. Future Trends and Developments in ZIF Connector Technology

As we look ahead, the evolution of ZIF connector technology is expected to be driven by the increasing demand for high-speed data transmission and miniaturization in electronic devices. The trend towards smaller, lighter, and more portable devices has led to the development of micro and nano ZIF connectors. These connectors are designed to provide reliable, high-speed connections in a compact form factor, making them ideal for applications such as smartphones, tablets, and wearable devices.

Another significant trend in the ZIF connector market is the growing emphasis on environmental sustainability. Manufacturers are increasingly focusing on developing connectors that are not only high-performing and reliable but also environmentally friendly. This includes using materials that are recyclable or biodegradable, as well as implementing manufacturing processes that minimize waste and energy consumption. In addition, there is a growing demand for ZIF connectors that can withstand harsh environmental conditions, leading to the development of connectors with improved durability and resistance to factors such as temperature, humidity, and vibration.

Lastly, the rise of the Internet of Things (IoT) and Industry 4.0 is expected to create new opportunities for ZIF connector technology. With billions of devices expected to be connected to the internet in the coming years, there will be a significant need for reliable and efficient connectivity solutions. ZIF connectors, with their ease of use and high performance, are well-positioned to meet this demand. To stay ahead of the curve, manufacturers should focus on developing connectors that can support high-speed data transmission, are easy to install and remove, and can withstand the rigors of industrial environments.

Frequently Asked Questions

What makes ZIF connectors different from other connectors?

ZIF connectors are unique because they require no force to insert a component into the connector. This is achieved through a lever or slider that, when moved, opens the contacts to allow the component to be inserted or removed. Once the component is in place, the lever or slider is returned to its original position, securing the component.

Are ZIF connectors durable and reliable?

Yes, ZIF connectors are known for their durability and reliability. The zero insertion force design reduces wear and tear on both the connector and the component, extending their lifespan. Furthermore, the secure locking mechanism ensures a reliable connection.

Can ZIF connectors be used with any type of electronic device?

ZIF connectors are versatile and can be used with a wide range of electronic devices. However, they are most commonly found in devices where components need to be frequently replaced or upgraded, such as computers and test equipment.

What precautions should be taken while using ZIF connectors?

While using ZIF connectors, it’s important to ensure that the lever or slider is fully open before inserting or removing a component to avoid damaging the contacts. Also, care should be taken not to force a component into the connector as it could damage both the component and the connector.

Are there any limitations or drawbacks to using ZIF connectors?

While ZIF connectors offer many advantages, they are typically more expensive than other types of connectors due to their complex design. Additionally, they are larger in size, which may not be suitable for all applications, particularly in compact devices.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!