Every electronic engineer has faced the same challenge: how do you make multiple devices communicate without a jungle of wires? Back in 1982, Philips Semiconductor (now NXP) introduced a solution that would simplify electronics design forever—the I2C (Inter-Integrated Circuit) protocol. From smartphones to industrial controllers, I2C quietly connects devices behind the scenes. But how exactly does it work, and why is it so widely used? Let’s take a closer look.

Introduction to I2C Communication

What is the I2C Protocol ?

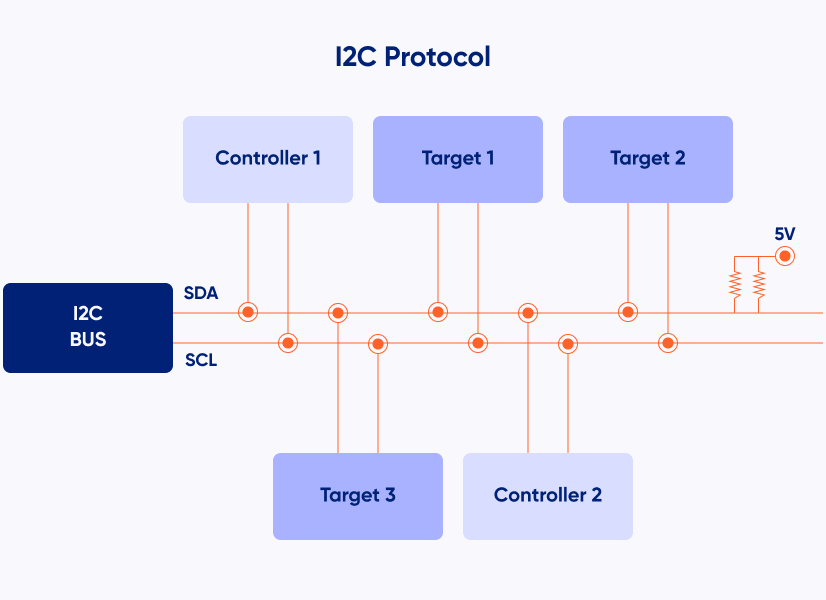

Imagine you have a master microcontroller that needs to talk to several sensors on a board. Instead of running a separate wire to each device, I2C allows them to communicate over just two lines: SDA (Serial Data) for transferring information and SCL (Serial Clock) to keep the timing in sync.

This simplicity is one of the reasons I2C became so popular. Every device on the bus has a unique 7-bit or 10-bit address, so the master knows exactly who it’s talking to. No messy wiring, no confusion—just a clean, scalable communication setup.

Common Applications of I2C in Electronics

You probably interact with I2C devices every day without even realizing it. In consumer electronics, it links touch controllers, displays, and power management chips in smartphones and laptops. In automotive systems, it connects sensors monitoring temperature, pressure, and speed. Industrial automation uses I2C to coordinate multiple microcontrollers, ADCs, or DACs, while embedded systems rely on it to communicate with EEPROMs, real-time clocks, and sensor arrays.

Popular I2C devices include:

- temperature and humidity sensors

- real-time clocks

- EEPROM memory modules

- OLED and LCD displays

- digital-to-analog and analog-to-digital converters

Its reliability and minimal wiring make I2C ideal for both prototyping and large-scale production.

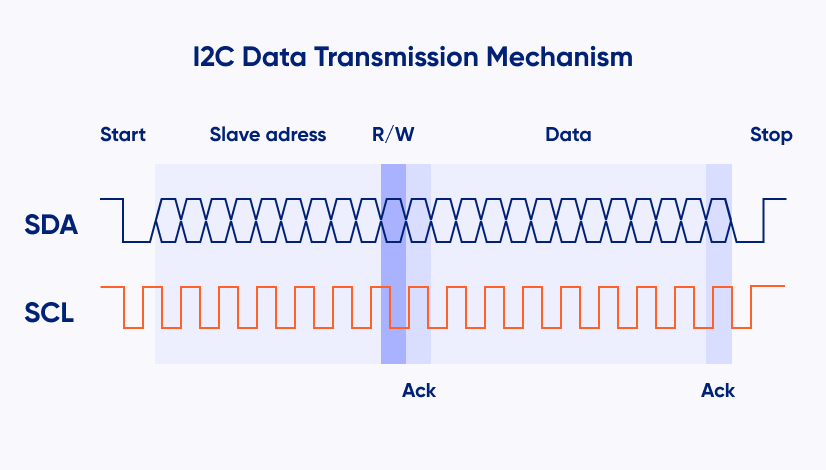

I2C Data Transmission Mechanism

The magic of I2C is in its simplicity and structure. Data travels synchronously, meaning every bit is aligned with the clock. A typical exchange starts when the master issues a start condition, pulling SDA low while SCL is high. It then sends the device’s address and the read/write instruction.

The slave responds with an acknowledge (ACK) signal, confirming it’s ready. Data flows in 8-bit packets, each followed by another ACK, and finally, the master ends the transaction with a stop condition. This careful choreography ensures that even a bus with multiple devices operates smoothly.

I2C Connection Configurations

Single Master with Multiple Slaves

The most common setup is straightforward: one master microcontroller talks to several slaves. Each device listens only when addressed, preventing accidental conflicts. It’s a simple and predictable communication pattern, perfect for sensors, memory chips, and small peripheral modules.

Multiple Masters with Multiple Slaves

I2C can also handle more complex networks where multiple masters may need to initiate communication. To prevent collisions, I2C includes an arbitration mechanism: if two masters transmit at the same time, the one sending a “1” while the other sends a “0” detects the conflict and backs off. This feature allows more advanced setups without compromising reliability.

Advantages and Disadvantages of I2C

Advantages of I2C

One of I2C’s strongest points is efficiency. With just two lines, you can connect dozens of devices. It’s scalable, flexible, and supports multiple masters. Built-in ACK/NACK signals ensure reliable communication, and standardized speeds range from 100 kbit/s to 3.4 Mbit/s.

I2C Speed Modes

| Mode | Speed (kbps) | Typical Use Case | Notes |

| Standard Mode (SM) | 100 | Low-speed sensors, RTCs | Most common in simple designs; very robust. |

| Fast Mode (FM) | 400 | Displays, ADCs | Widely supported; good compromise of speed and compatibility. |

| Fast Mode Plus (FM+) | 1000 | Medium-speed industrial devices | Allows higher throughput; increases power consumption. |

| High-Speed Mode (HS) | 3400 | Advanced displays, high-speed sensors | Requires special master/slave devices; not universally supported. |

| Ultra-Fast Mode (UFm) | 5000 | Write-only devices | Introduced in I2C spec v6; unidirectional (no read support). |

Disadvantages of I2C

Of course, no protocol is perfect. I2C is slower than SPI, comparable to UART and reliable only over short distances. Software must handle addressing and handshaking, adding some complexity. Additionally, correct pull-up resistor sizing is important for stable communication.

- Two lines (SDA & SCL) carry all data.

- Multiple devices with unique addresses can share a single bus.

- Supports single or multiple masters.

- Reliable synchronous communication with ACK/NACK.

- Ideal for short-distance, low-to-medium speed systems.

- Proper hardware setup ensures stability.

I2C isn’t the fastest or simplest protocol, but it strikes a balance between efficiency, scalability, and reliability. That’s why it remains the backbone of sensor networks, embedded devices, and consumer electronics. Next time you see a cluster of chips quietly communicating on a PCB, there’s a good chance they’re speaking I2C.

Need help implementing I2C in your design? Contact the Riverdi team to optimize your communication setup.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!