- Introduction to Sunlight Readable Displays

- The most important parameters of Outdoor LCD Displays

- Contrast ratio of Outdoor LCD Displays

- How sunlight affects Outdoor LCD Displays readibility

- Reflections – Protection glass, Air bonding and Optical Bonding in Sunlight Readable Displays

- Riverdi’s High Brightness LCD TFT display lines

- Outdoor LCD Displays – operating and storage temperatures

Introduction to Sunlight Readable Displays

The article covers the most important parameters of LCD TFT Sunlight Readable Displays that need to be considered if the LCD display is to be used in the outdoor environment. It means we will cover issues like contrast, brightness, and reflections, and how these parameters influence what we see; and what we do see, in fact, is the contrast, not the brightness of a display. Contrast is derived from the value of brightness of a display and reflections of it, and hopefully by the end of this article, you will know exactly how it works, and how to get the best possible one.

The most important parameters of Outdoor LCD Displays

As the agenda presented outlines, we will go through items like contrast, because this is the key factor to see the image and content clearly. We will also mention sunlight and other light sources and how they influence what we see on the display. Then we will move on to reflections, display brightness, and at the end, how a display operates in different temperatures, as there are special displays solutions for the outdoor environment (very high or low temperatures).

Contrast ratio of Outdoor LCD Displays

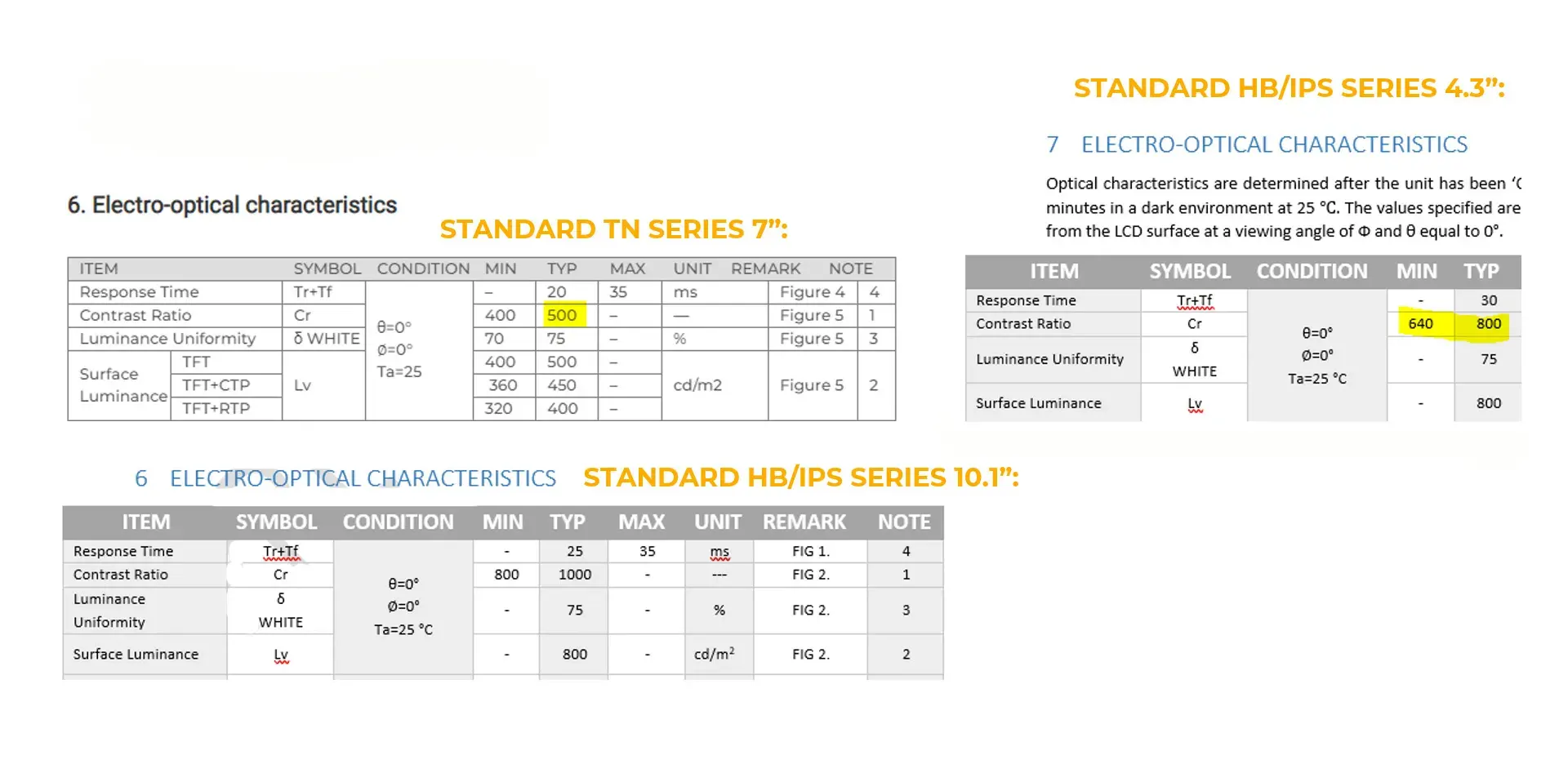

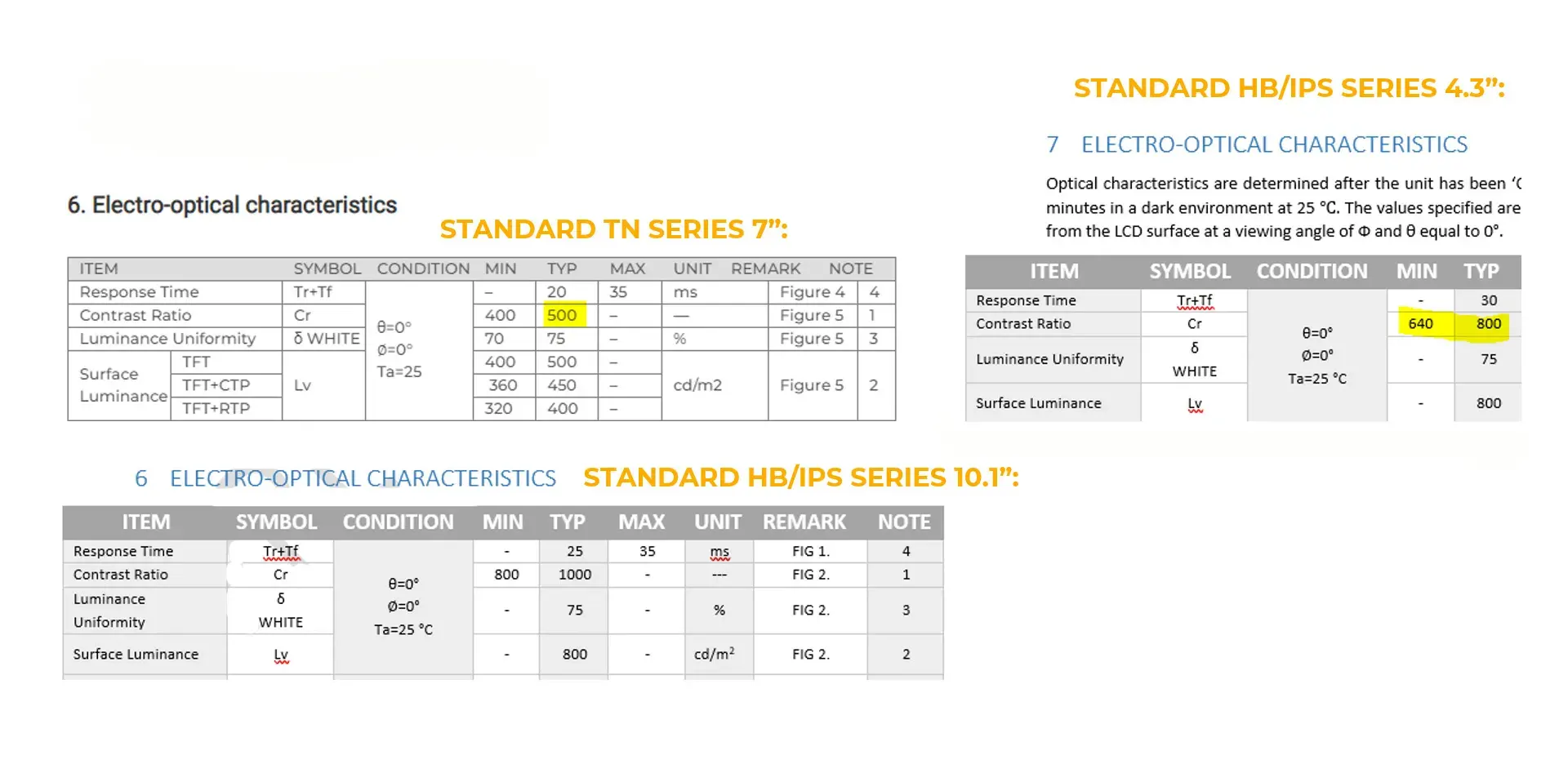

Contrast ratio is a parameter that you can easily find on every display data sheet. It is measured post-manufacturing and given to the customer in the form of a reference number. The contrasts from our data sheets in the examples above are a couple of hundreds high and this is standard for the industrial display type.

For low-end displays the contrast value range is 300 to 500 and for high-end ones it can go as high as 1000 to 2000. If we have a display with such high contrast, then we can see the image perfectly. The number will be different, however, if you buy a standard TV. If you go to the specification of the TV, you might find a number like 1 to 1,000,000, but it’s a little bit tricky and is not necessarily the most important to have. As we will see in the next part of this article, the true contrast in the real world is much lower than even the numbers given here for industrial displays, and could be even a hundred thousand times lower than you can see in a TV specification, and still see the picture clearly.

The first thing about contrast is the ratio of the bright parts of the display to the dark parts; this is simple to measure – just measure the brightness. If we imagine the picture of a black and white spiral is on an LCD display, we can measure how many candelas there are in the white part. Let’s say it’s a thousand candelas display or the like. Then, having the backlight on and the pixels blocked, we can measure how many candelas there are in the black part. Because the difference between them is big, we will see this black and the other parts white, but this is not true black. Because pixels are not perfect, and some light is coming out of them (they are not blocking the light perfectly), when we measure brightness, the result could be around 10 candelas.

In some TVs, like OLEDs for example, the contrast can be very high because when the TV has pixels turned off, they are not emitting any light, and what we experience is true black. I suggest you go and see this kind of TV at a store because it’s a different kind of experience. If you have a completely black background, true black, this is not something that we are used to in standard TVs with a TFT LCD display. That is why we could have contrasts like a couple of hundreds or a thousand, or a million, depending on how you measure that.

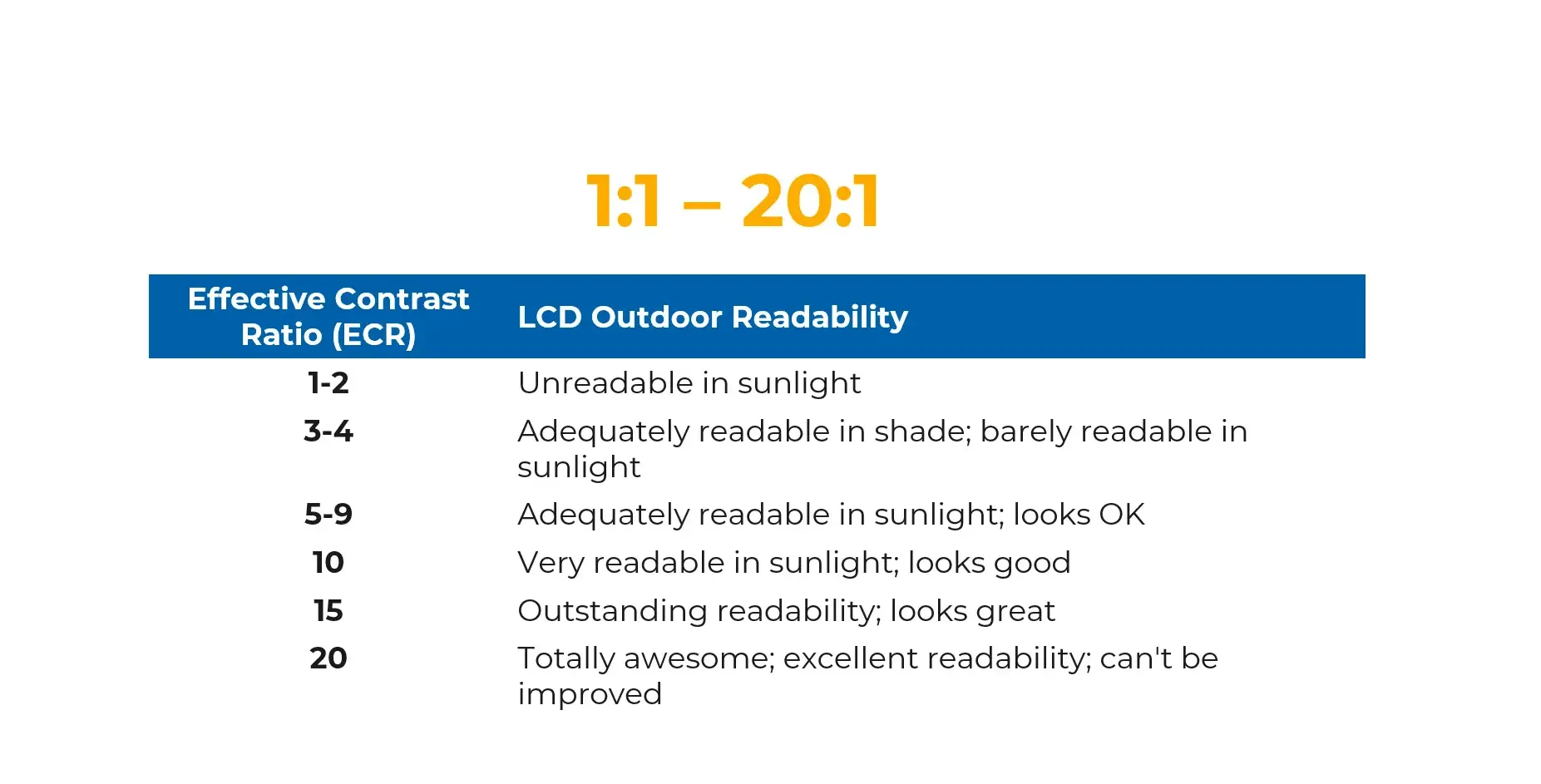

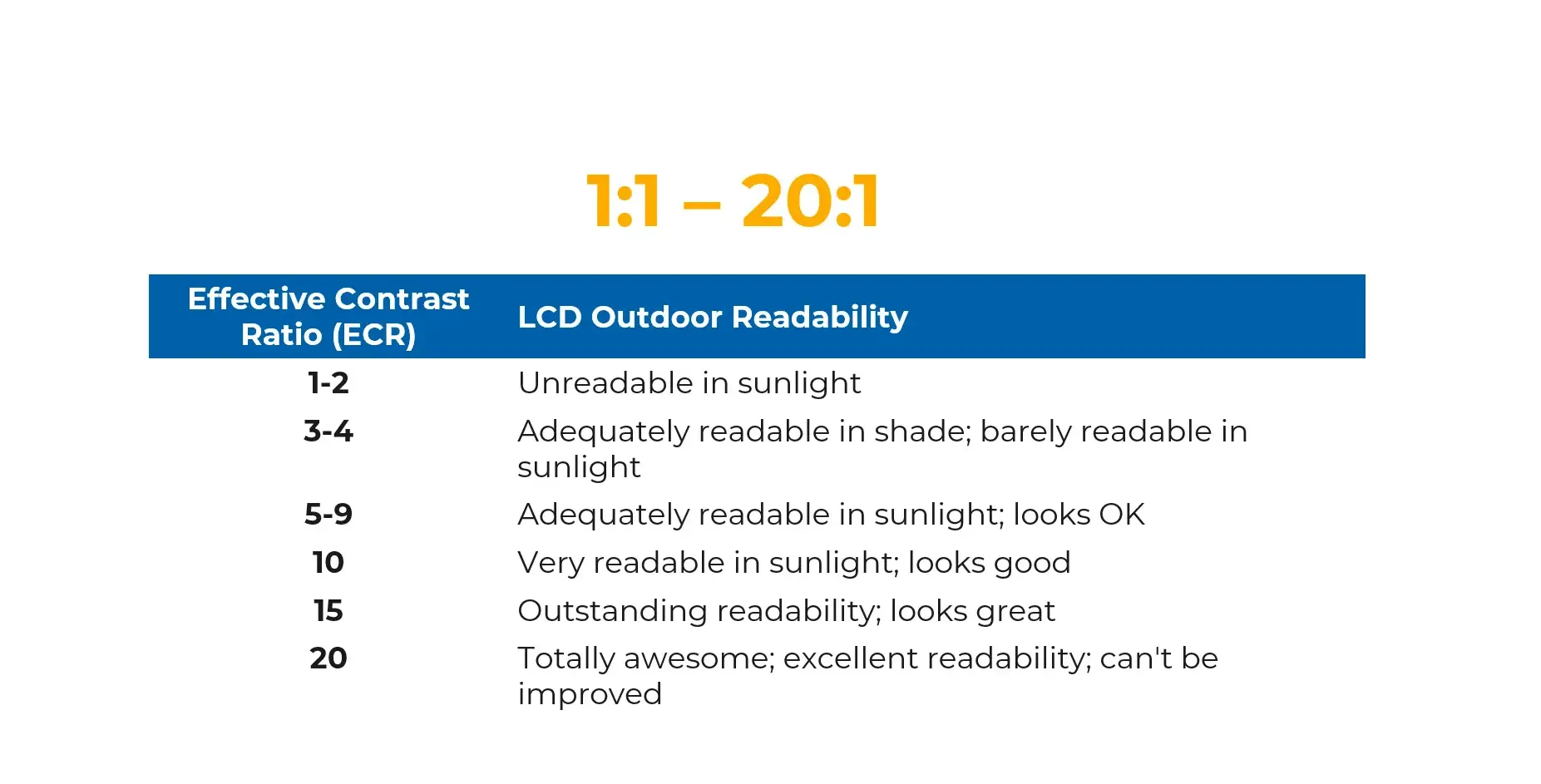

Going more into detail, let us consider the real contrast that we call Effective Contrast Ratio (ECR). In our data sheets we have a CR, Contrast Ratio. It is a value that we measure under perfect factory conditions, in a dark room where we just measure the white and dark parts of the screen without any reflections. In the real world though, we have light in the room or outdoors. As every surface, which is not true black, reflects sunlight, we get reflections which add brightness to it. The brightness adds to both, the black and white parts, and that lowers the contrast significantly.

The table above presents an Outdoor LCD Display Readability scale, and as you can see, the Effective Contrast Ratios are very, very low comparing to the datasheet that we have seen before, where it was 500 to 1 or even 1,000,000 to 1 in a TV specification. Here we have only 1 to 2, or 3 to 4 and up to 20 and you can see that reasonable readability starts at 5. 5 is acceptable contrast and most of the things we see are between 5 to 10. As you can see when Effective Contrast Ratio is 10, it is well readable and if it 15, it is outstanding and 20 is excellent! What you see right now here on your screen could be like a 15 to 1 or a 10 to 1 contrast and we still see a perfect image.

Of course, if we go too low, close to 1, then we cannot see anything because the values of the bright and dark will become equal.

The real contrast is much lower than what can we see in the specifications, that is why the contrast itself in a specification is not the most important factor for a bright environment. Were we to work in a dark environment maybe we would look at the contrast and say a display that has 1,000 to 1 is better than a display that is 500 to 1, but in real life when we have a bright environment these two displays will look pretty much similar and will be similarly readable because the real value of Effective Contrast Ratio will be much lower and it is connected with other factors, not the contrast itself.

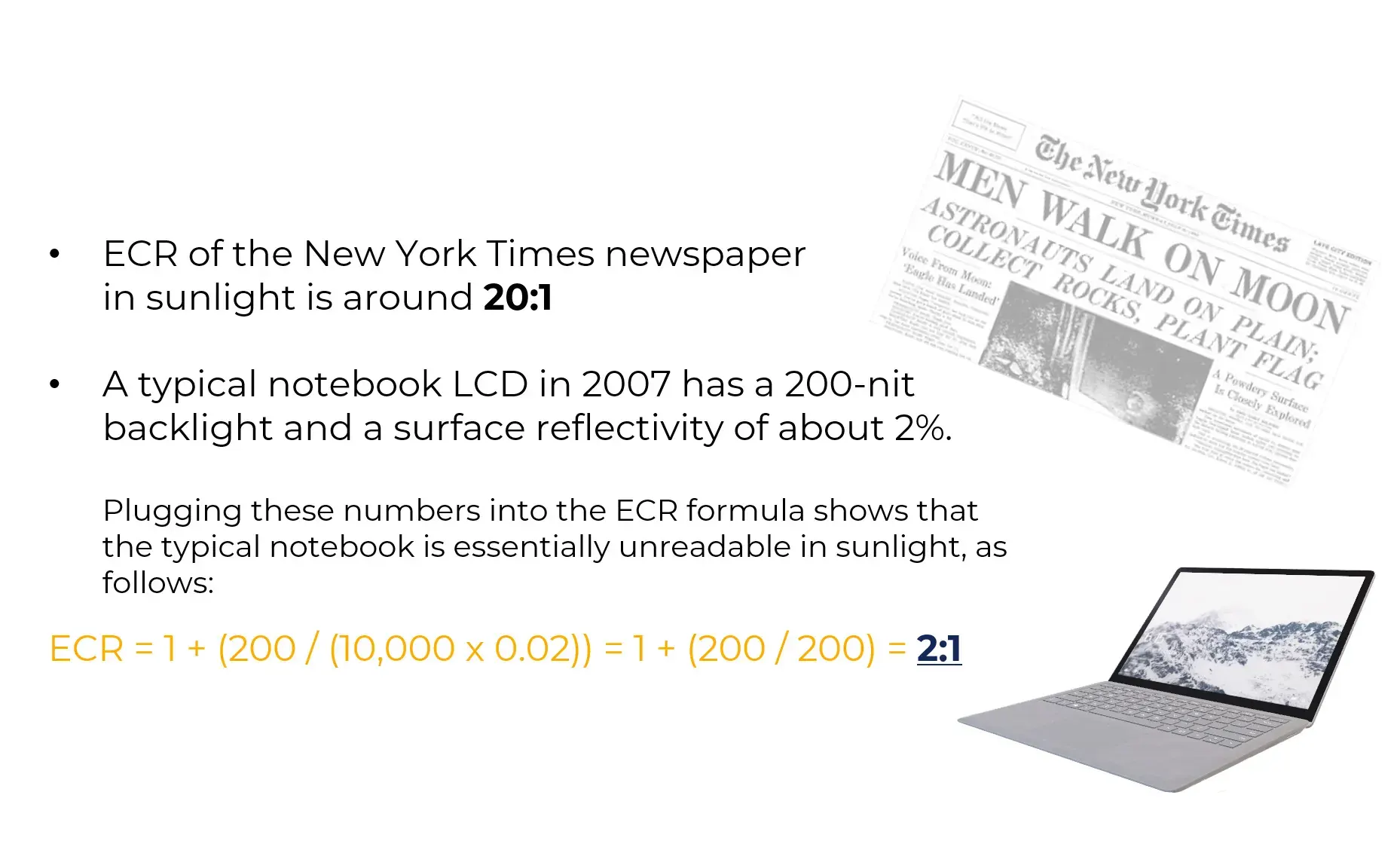

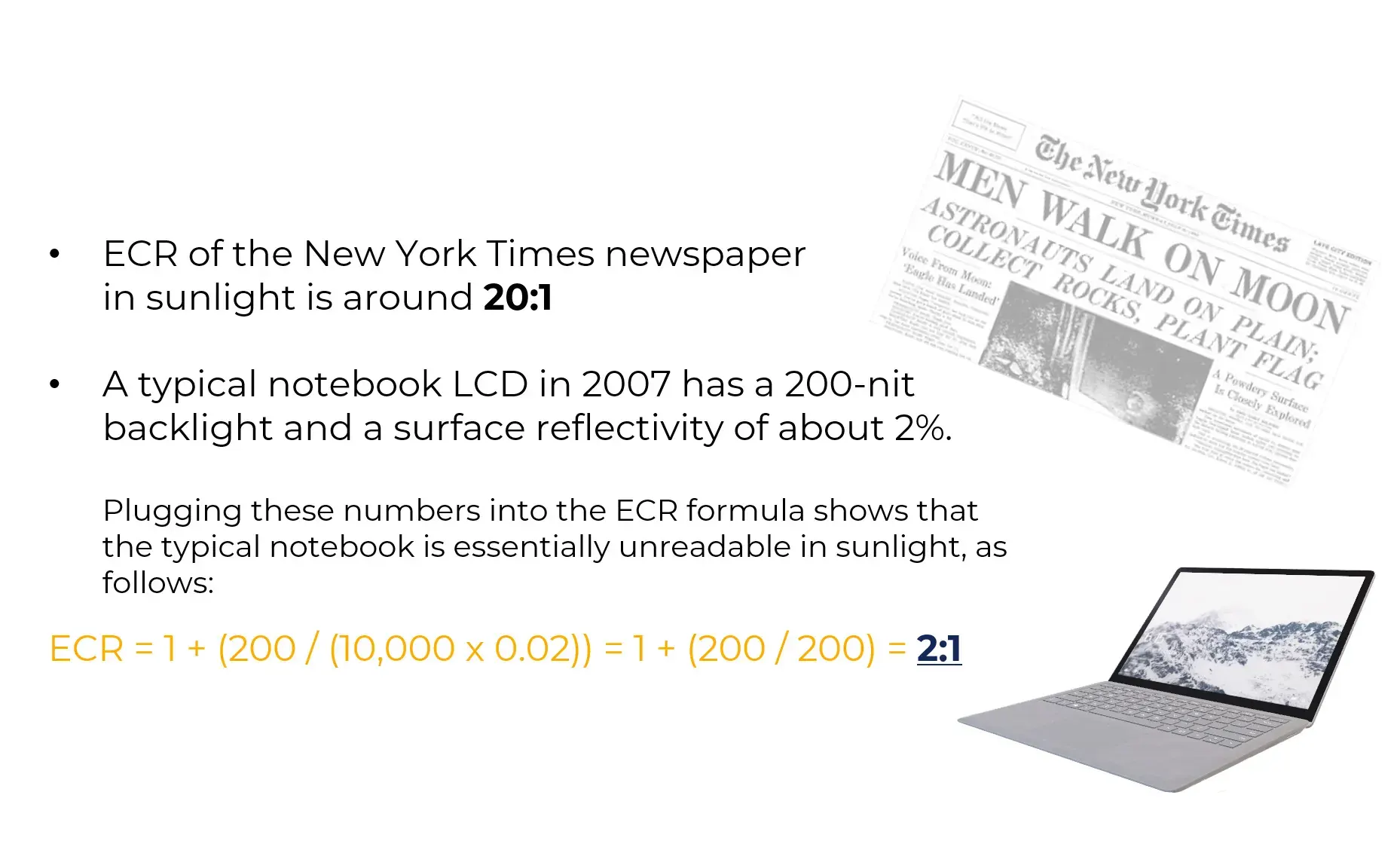

The graphic above presents some additional calculations. As you can see, if we take a typical newspaper, we can expect a contrast of 20 to 1 in sunlight. This is very low, but perfectly readable and we would say that the newspaper is one of the best that you can see and clearly read in the sunlight. Then we have some information about notebooks where the brightness is lower and a formula where the ECR is calculated. We will go into detail of how to calculate it later, but as you can see, the typical notebook in 2007 had a screen brightness of 200, maybe 300 candelas. Nowadays the notebooks are going into higher brightness, but then, in 2007 we could expect very low contrast, that is why it was very hard to read or work with that kind of notebooks in the sunlight.

How sunlight affects Outdoor LCD Displays readibility

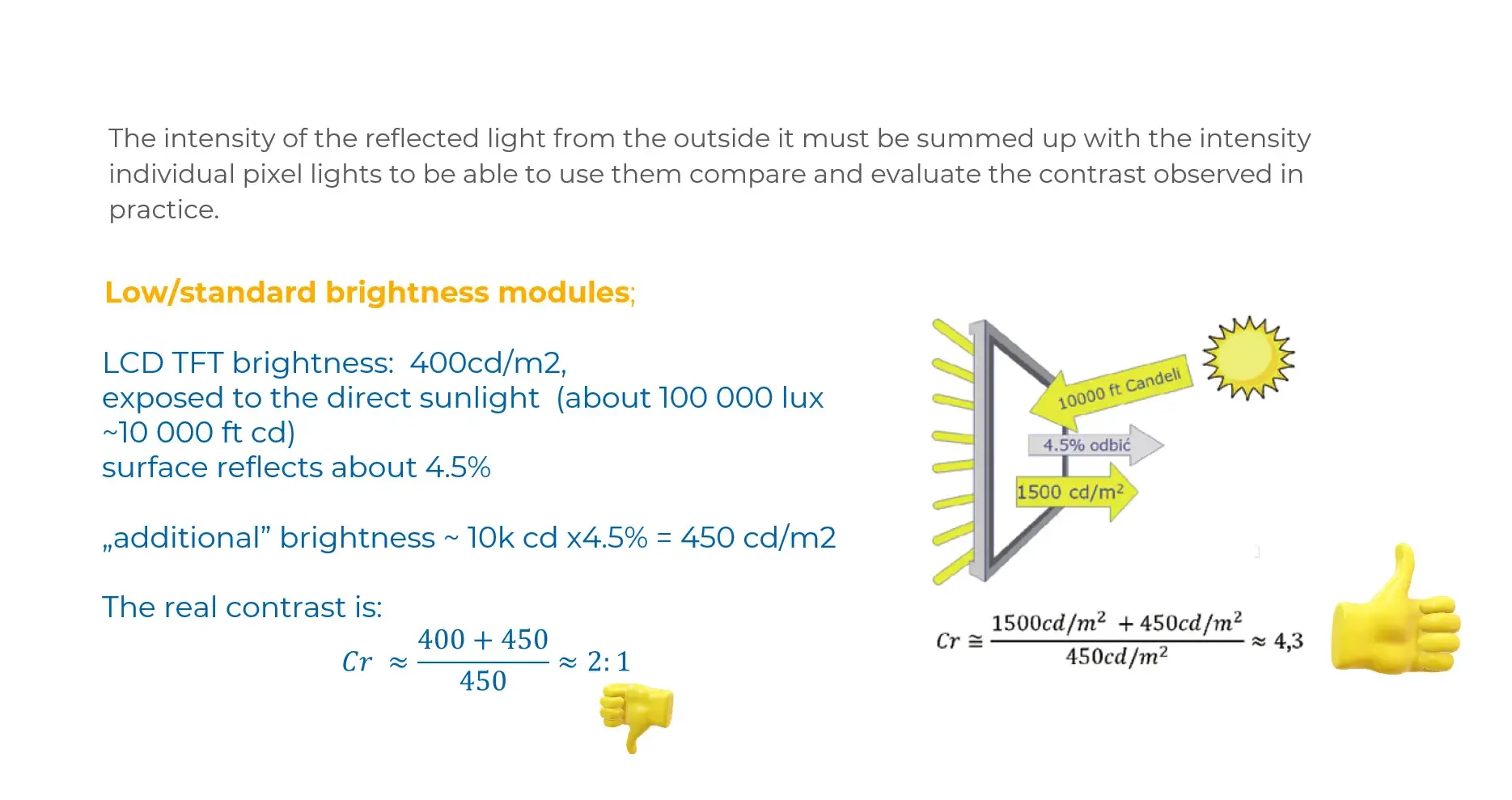

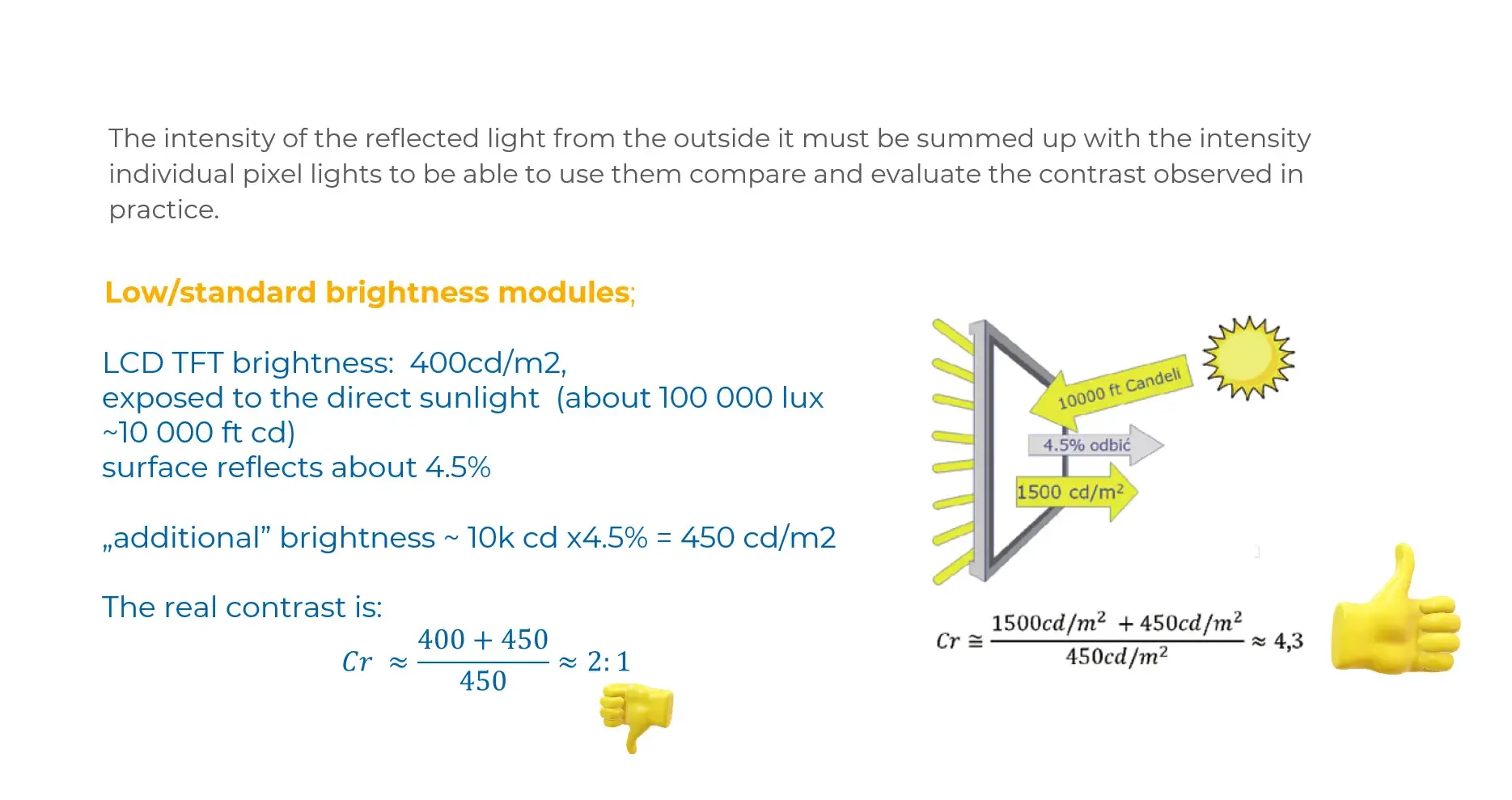

Now let us go a little bit more into detail and take the example with the numbers of a middle brightness display which is 400 candelas. As you know our high brightness IPS displays are 1000 candelas by standard, but here we have intentionally a lower brightness for the purpose of the calculation. So, we have 400 candelas, and we have a 400-contrast ratio, for easy calculation. Then we take our display outdoors to the sunlight, where we can expect about 10,000 candelas brightness of the light and assume four 4.5% reflections.

That means the surface of the display will reflect 4.5% of the light that is coming. In this case it will reflect about 450 candelas, and it will reflect on all the surface, both on the bright and dark parts. So, whatever we had before, if we go outdoors, we need to add the reflections and they are added into the whole surface, into the bright part, and into to the dark part and then the Contrast Ratio value is completely different, and we go down from 400 to 2 to 1 only.

As we have already learnt, 2 to 1 is rather unreadable or uncomfortably readable. We don’t like to look at this kind of displays because we need to make an effort and really try hard to actually see what is there. So, it is way too low, so how can we improve that in Sunlight Readable Displays? We can actually do two things. The first thing is easy, we can increase the brightness, so we go up and if we go to, for example 800 or 1000 candelas, we will have the contrast ratio of 3 to 1 or whatever. What else can we do? We can decrease the reflection rate, so we can change the surface of the display and make it to reflect lower. That is why we sometimes use an anti-reflective coating on the glass. And from, for example 4,5%, we will go down to maybe 1%, so the reflection brightness will go to 100 candelas. Then the real contrast, after a fast calculation would be 500 divided by 100, that means 5 to 1. So, if we decrease only the surface without even changing the brightness of a display, we are able to go with the contrast from 2 to 1 to 5 to 1, which will be good enough, or even perfect in sunlit conditions. Usually, we do both. We try to increase the brightness and try to decrease the reflections as much as possible, because the reflections in outer cases are high.

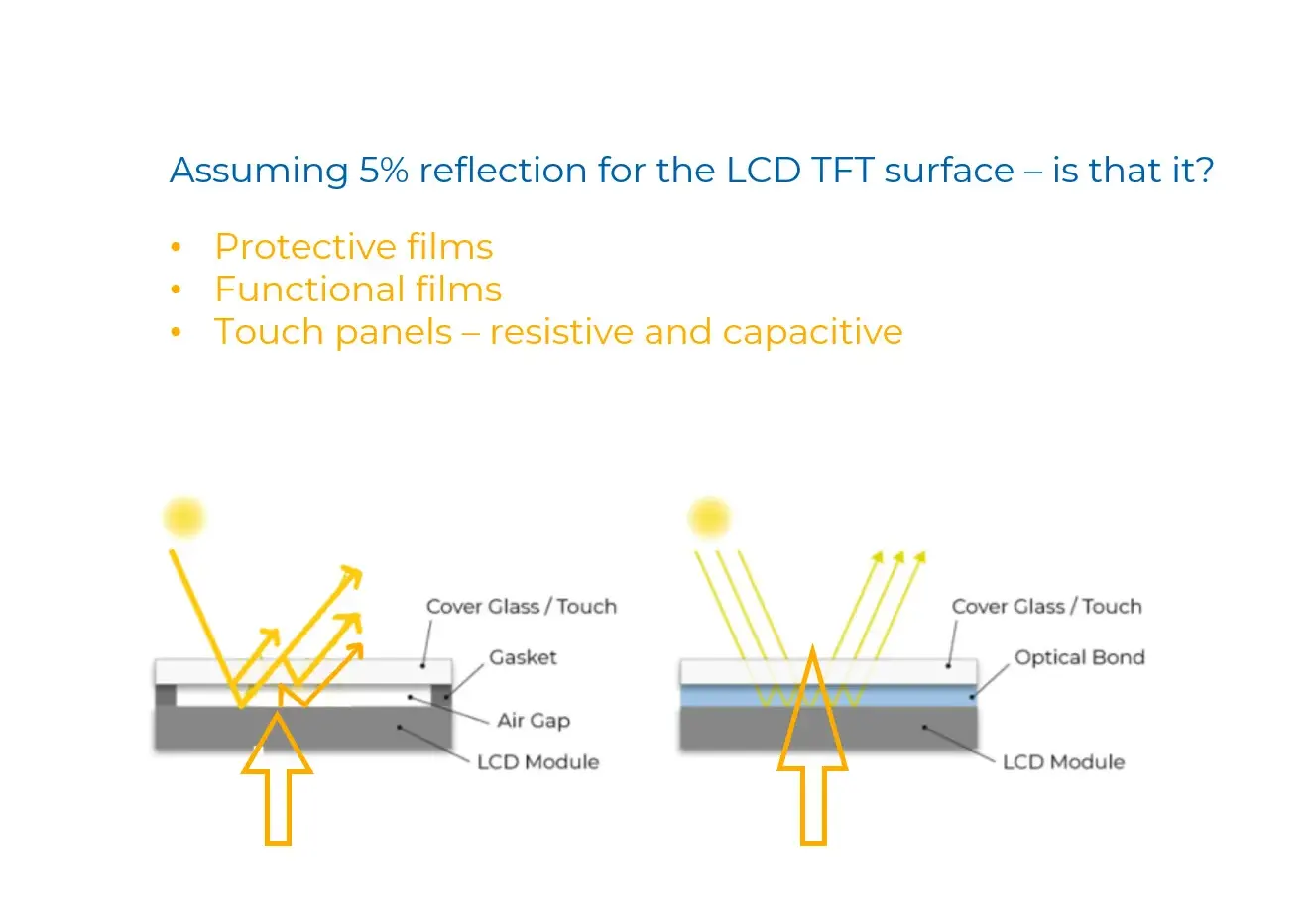

Reflections – Protection glass, Air bonding and Optical Bonding in Sunlight Readable Displays

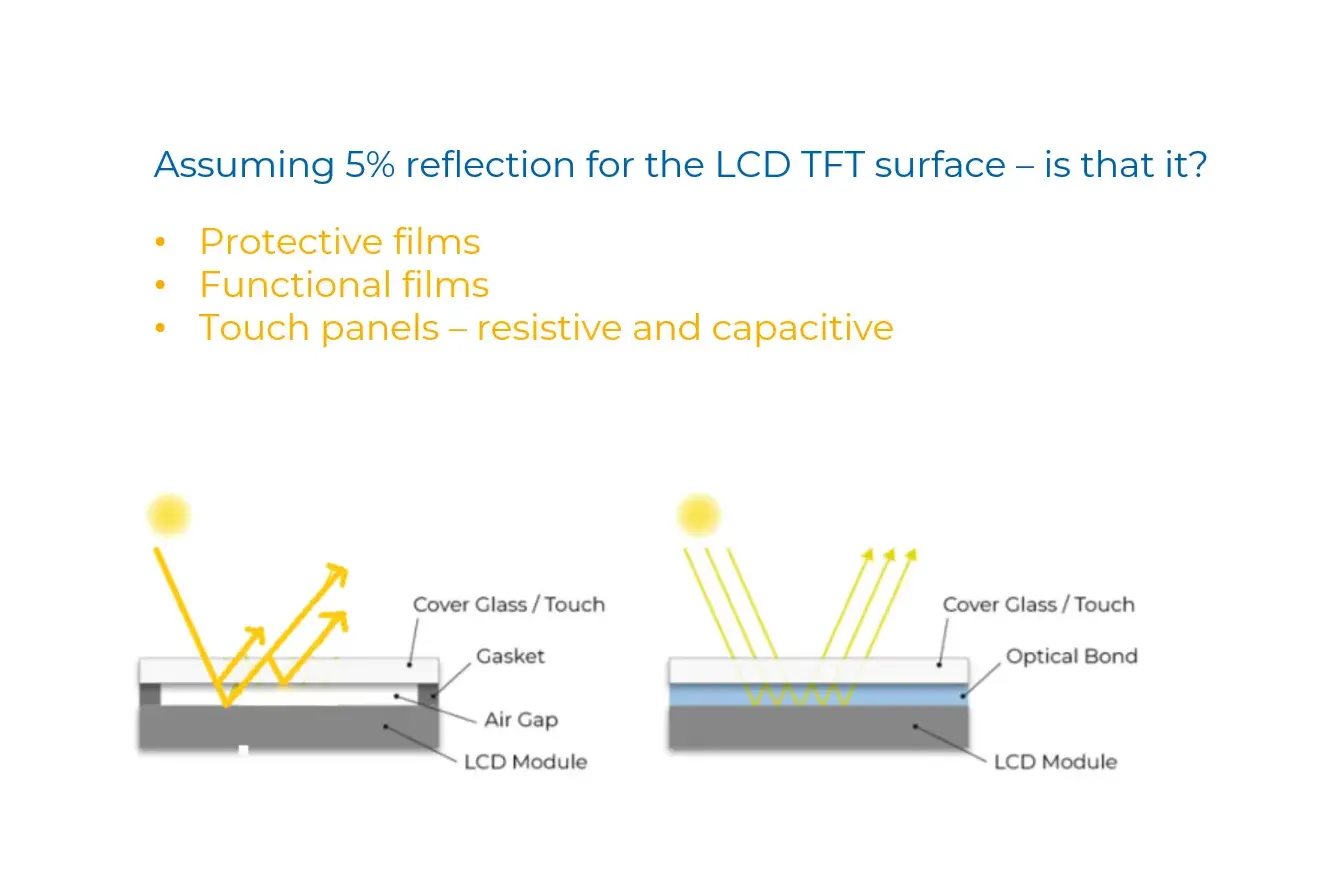

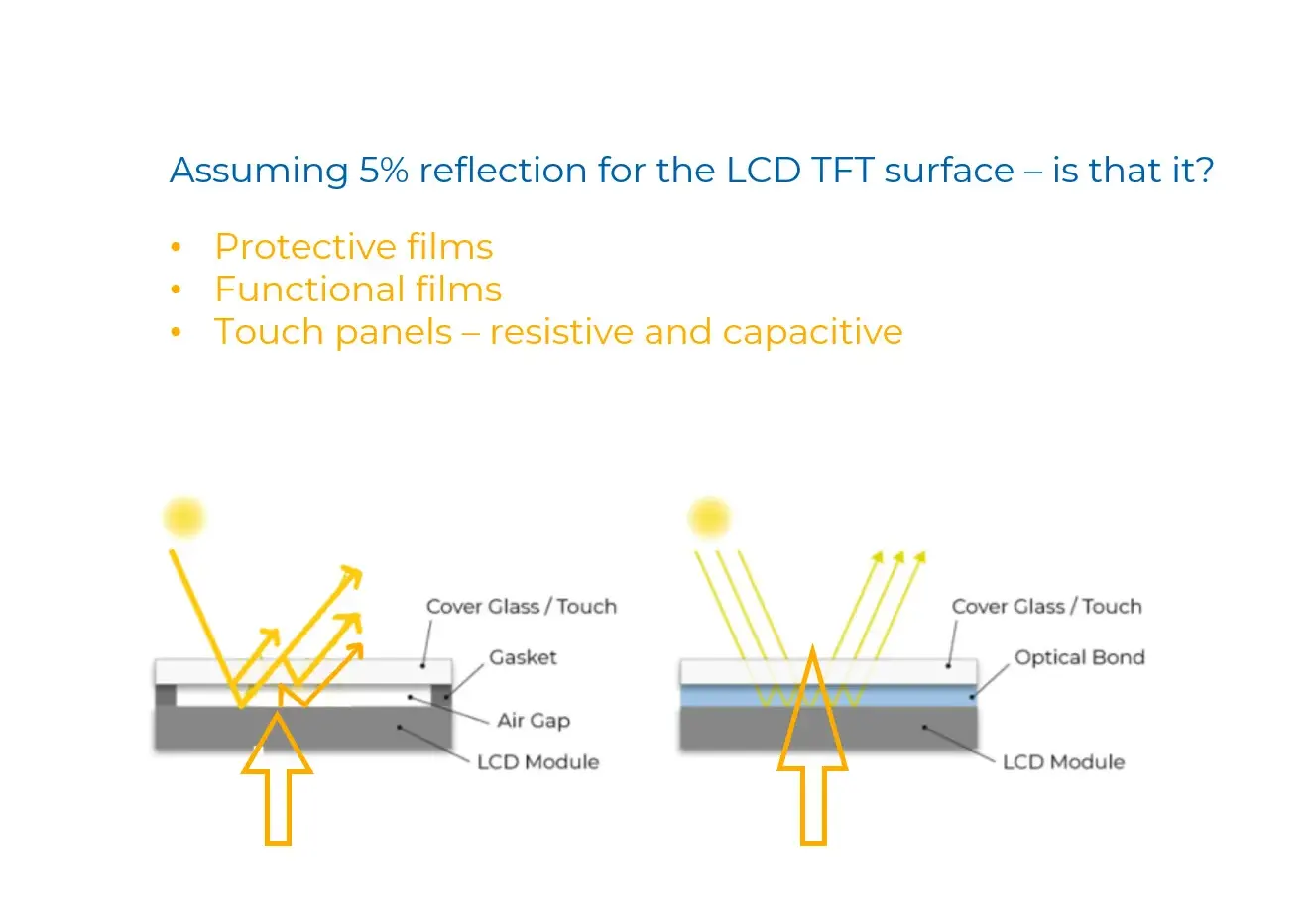

If we have a LCD display installed outdoors, we need not only an anti-reflective layer to reduce the reflections, but we also have to protect the display, usually by adding an additional glass. Because it is outdoors, we need to protect the display from vandalism, and also from the environment itself – from water, dust, and everything that we can expect outdoors. So, we put additional glass. Sometimes it is just a covered glass, sometimes it is a glass with touch, depends on the application, and they are usually separated by a layer of air. It has a lot of benefits: mechanical benefits, economical, easy assembly and also, if the glass gets destroyed, the display might still be OK; and we can replace just the glass without replacing the whole display.

But from an optical point of view, this solution has a lot of disadvantages. If the additional glass is not optically bonded to the surface of the display, we have air in between. That means we have more reflections. We have reflections from the glass itself, from the glass to the air, and from the display again because the glass is an optically different environment than the air. So, we have sometimes even 10% of reflections or more. That is why we need to increase the brightness as well. It is not that easy to handle, so the contrast could again be not good enough. Looking at our example, if we have 10% of reflections even with increasing the brightness to 2000 candelas, without lowering the reflections, we have a contrast of 3 to 1. That, again, makes the display go from unreadable to barely readable just by increasing the brightness and reflections.

The other solution is to add optical bonding. If we add optical bonding, that means we remove the air from between the display and the cover glass, and the optical bonding material will be as close as possible to the glass and to the display, then from the light point of view this will be the same environment. If we do not change the environment we have no reflections, like we have a big piece of glass inside. So optical bonding is removing quite a lot of reflections and also is improving the brightness of the display because if there is an air gap, the light from the display itself is also being reflected and we lose a few percent of the brightness. If we have optical bonding the light from the display just goes out and only the external light reflects on the display surface, so we have less reflections.

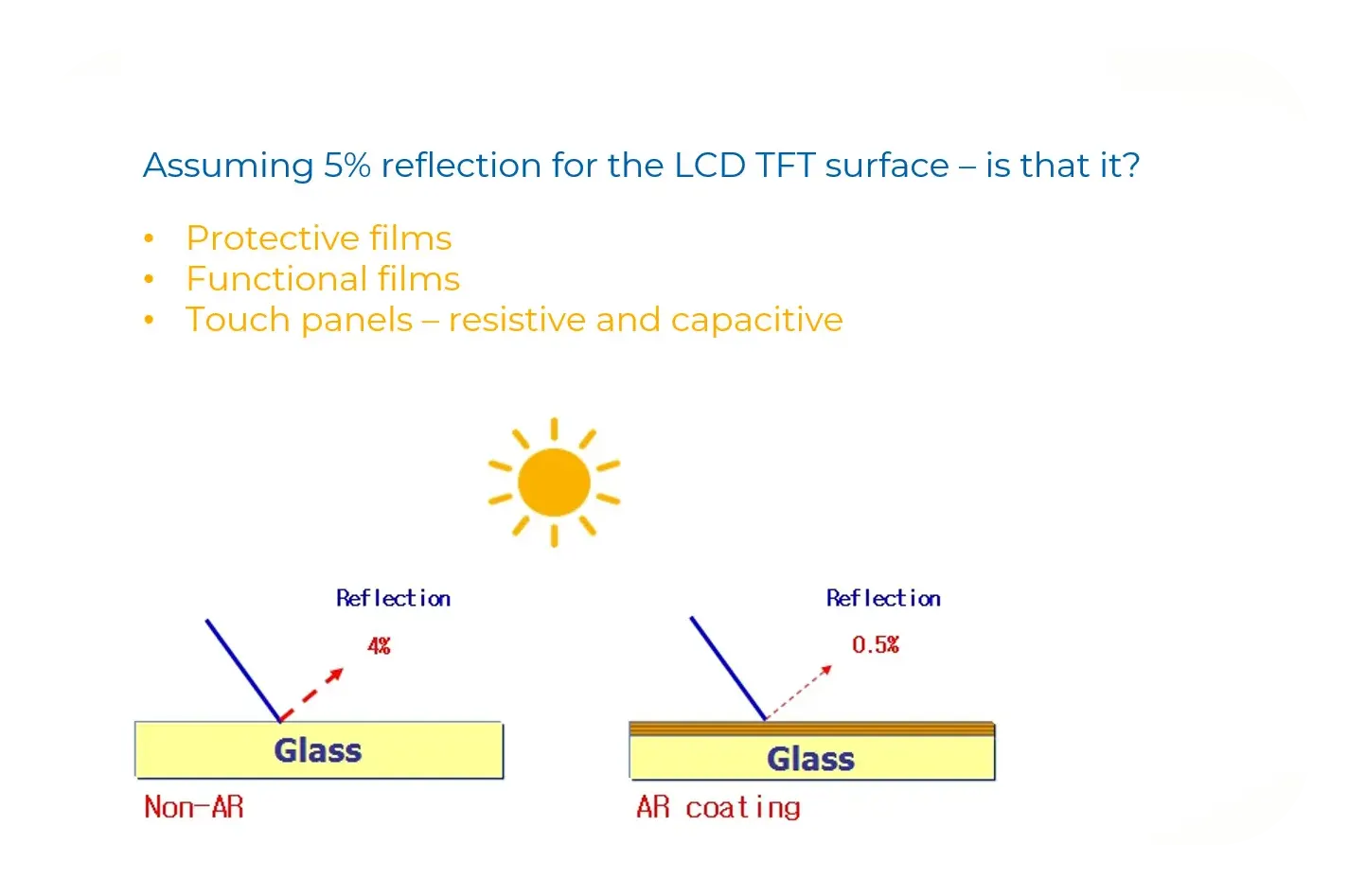

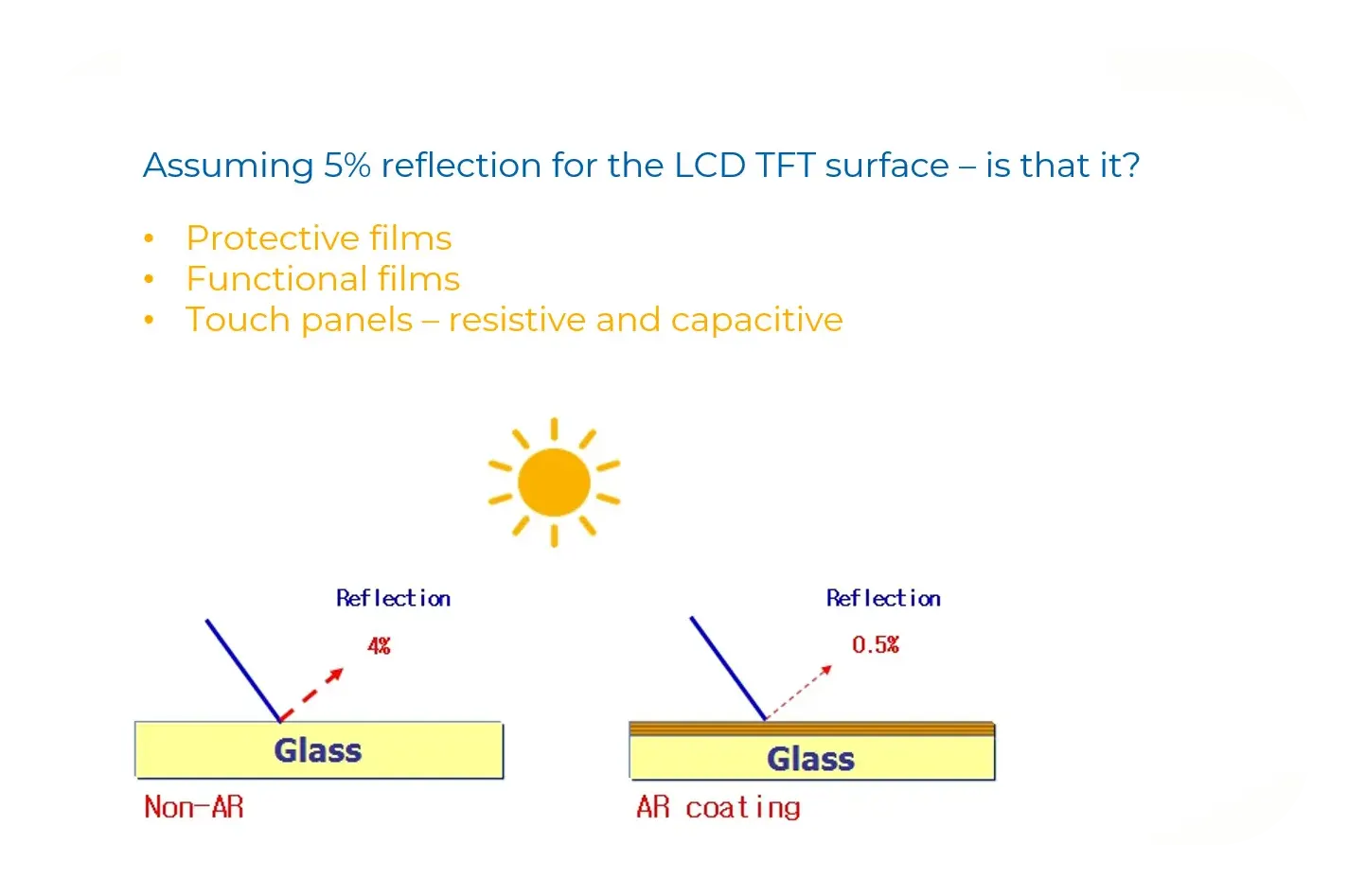

A more detailed explanation is pictured above. This is the situation with the display light going out from the display through the air gap and cover glass. 95% of it will go out but 5% will be reflected. Some of it will eventually go out but some not and it will result in blurring the display a bit. If we use optical bonding the image will be way clearer. If you have a chance to compare an air bonded display and an optically bonded display you will see that with the optical bonding the colors are better, more vivid and the image is literally clearer, because in this situation the whole light is just going out without any reflections scattering or the like.

The coating is adding an extra layer to the surface. Usually, it is a glass so we add this coating to the glass to decrease reflections. As it was mentioned before, typical glass reflection is 4% or 5%. If we add something that we call AR coating that is Anti-Reflective coating, we can decrease this number to 1% – 2.5% so it results in a big difference in contrast that we see as the viewer of the display.

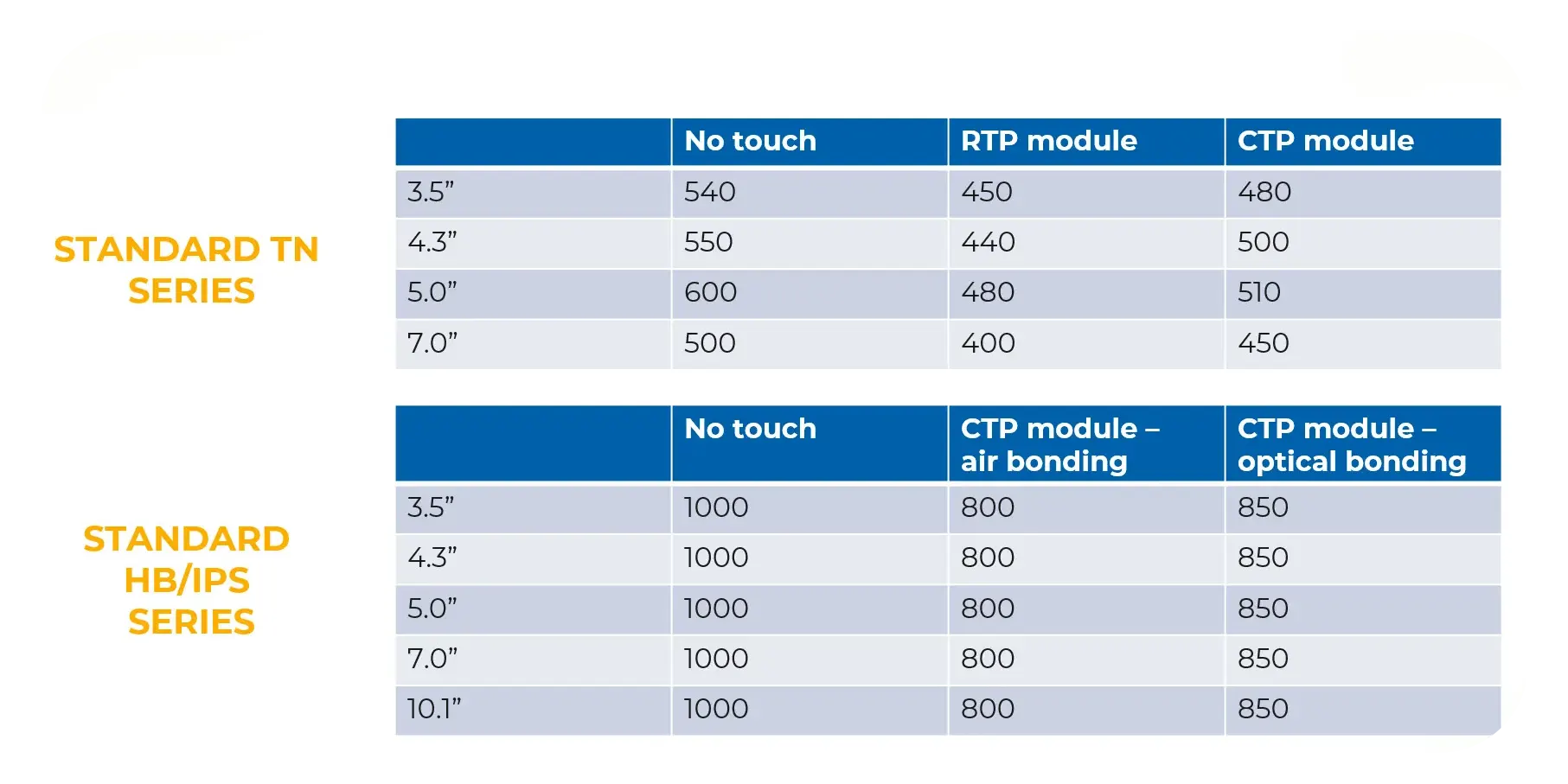

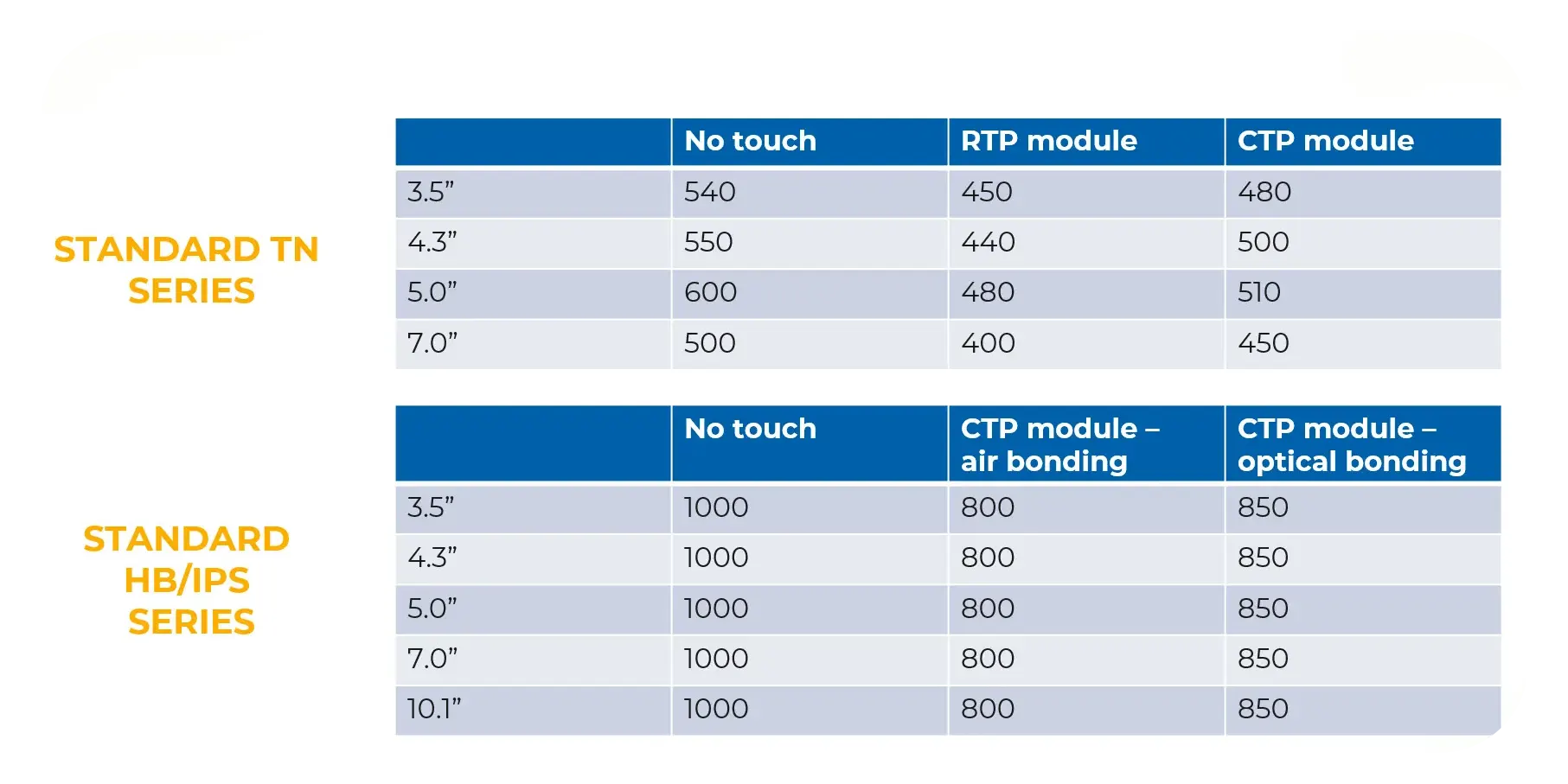

Riverdi’s High Brightness LCD TFT display lines

Now a quick reminder of Riverdi’s display lines. First, we have our old generation display line that was based on TN glass, Twisted Nematic standard glass. When we were introducing this line, most of the displays on the market at that time were 200 to 300 candelas. Our line was the industry’s higher standard and Riverdi’s displays were 500 to 600 candelas. Nowadays, the brightness is too low, that is why we decided to introduce a new line. We changed the glass from TN to IPS to have all the viewing angles possible and to have better colors and we also, at the same time, increased the brightness to 1000 candelas.

1000 candelas really is a universal number that we can use indoor in a very bright environment, like a bright medical room, or industrial facilities, or a coffee machine close to the window, where we have sunlight coming in from the window. With 1000 candelas we can have a perfect image and clear display and this 1000 candelas also allow us to build outdoor devices if we keep the reflection low. We can do it either by adding some shadow, so not having the direct sunlight, or having some additional anti-reflective layer on the last surface that would be typically glass. As you can see in the table above, if we add something on the top of the display, that is typically a touch screen, then the brightness goes lower because of the reflections. The glass is also not perfectly transparent. The typical glass has 95% to 97% percent of transparency, so few percent is lost in the glass itself, the rest is lost because of reflections. As you see if it is air bonded, we lose more comparing to optical bonded. When we have optical bonding, we lose less because there is no internal reflection. These numbers in our table are very conservative. In the real world they are typically higher, but this is the lowest you can expect. So typically, we could lose 10% to 12%, but we try to be conservative that is why we show 850 candelas so 15 percent down and this is the lowest that you can expect from our displays with pickup and pickup optically bonded. For the old generation line, we have also a version with resistive touch. Resistive touch includes more layers, we have another air gap which is necessary for us to press, because resistive needs to be mechanically pressed, that is why we have even lower brightness, so there are more reflections than with typical pickup without optical bonding.

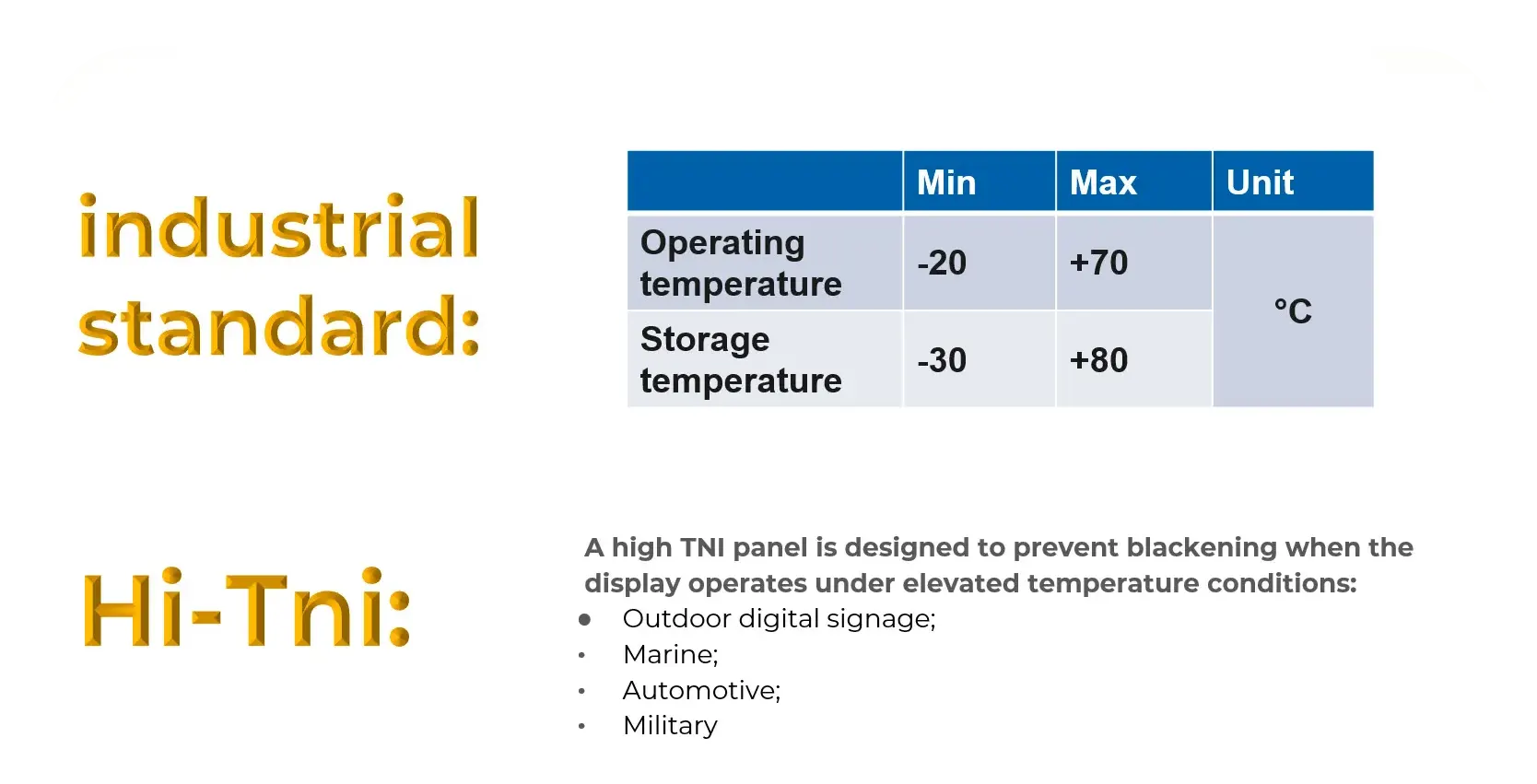

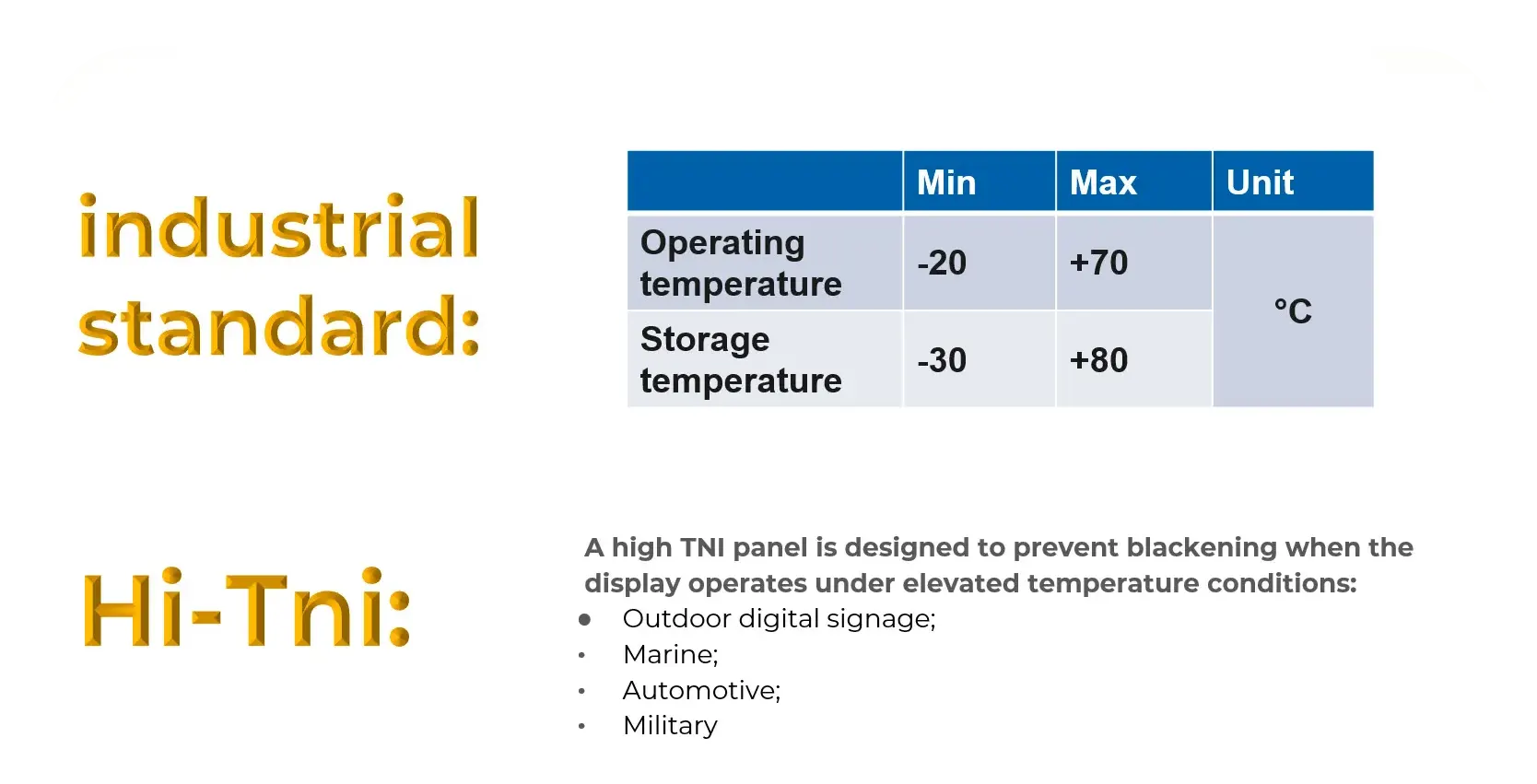

Outdoor LCD Displays – operating and storage temperatures

So, we already know how to make a display to be readable outside. We know that we can increase the brightness, or we can decrease reflections, and we have an image that we can see. Now we need to think, how to make the display operate in outdoor temperatures. As you know, our standard operating temperature range for the displays we offer is -20 to +70 degrees Celsius. This is an industry standard operating temperature. The storage temperature range is a little bit wider and is -30 to +80 degrees Celsius.

Some of our displays, e.g. the 7″, were tested in a range from -30 to + 80 degrees and were working, so the real practical working temperature range is higher than in the spec, but this is what we guarantee. But for real outdoor LCDs it is too low, it’s too low on both ends. So –20 degrees in many cases is not enough. In Scandinavia and many other countries, we may expect lower temperatures than -20 and we need -30 or -40 degrees of operating temperature for outdoor displays. On the high end it is also a problem because if we are out there in the summer and we have direct sunlight reaching the surface of the display, we can go higher than even +70 or +80 degrees. So, we need different technology. In a typical LCD we have liquid crystals. Liquid crystals need to be in a liquid phase to work and below the minimum operating temperature they starts freezing. That means it becomes solid and the crystals cannot move or move very slowly. Above the minimum operating temperature, in the range from -20 to +70 degrees Celsius it is in the liquid phase and works normally. We call this phase nematic, so the nematic phase is a phase where the light can be operated by a liquid crystal. The liquid crystal can change the polarization of the light, but it needs to mechanically move the crystals inside the liquid crystal cell, so it needs to be in the nematic phase. Below the minimum operating temperature, it becomes solid and cannot move. Above the maximum operating temperature, which is +70 or +80 degrees for typical displays, but sometimes only +50 degrees for consumer grade products, we will go to the isotropic phase. Isotropic means you cannot change the polarization of the light anymore. It becomes like all the light can go through the liquid crystal and you cannot control it with the voltage or anything, so you cannot switch the pixels on and off. That is why we have another solution that we call Hi-Tni displays. Hi-Tni means High temperature Twisted nematic – isotropic, and we use this technology for outdoor displays for example for the marine, automotive, and military industries.

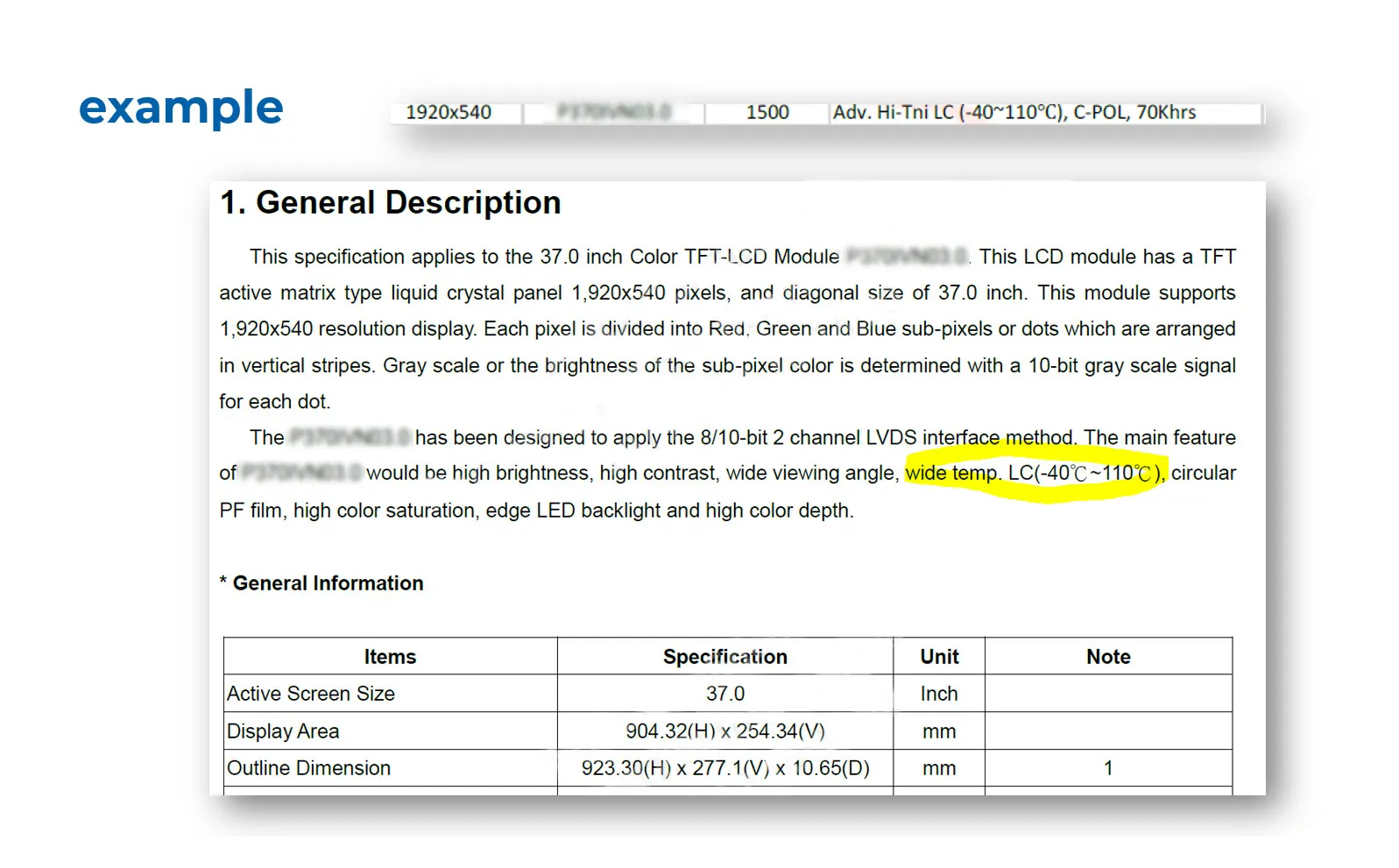

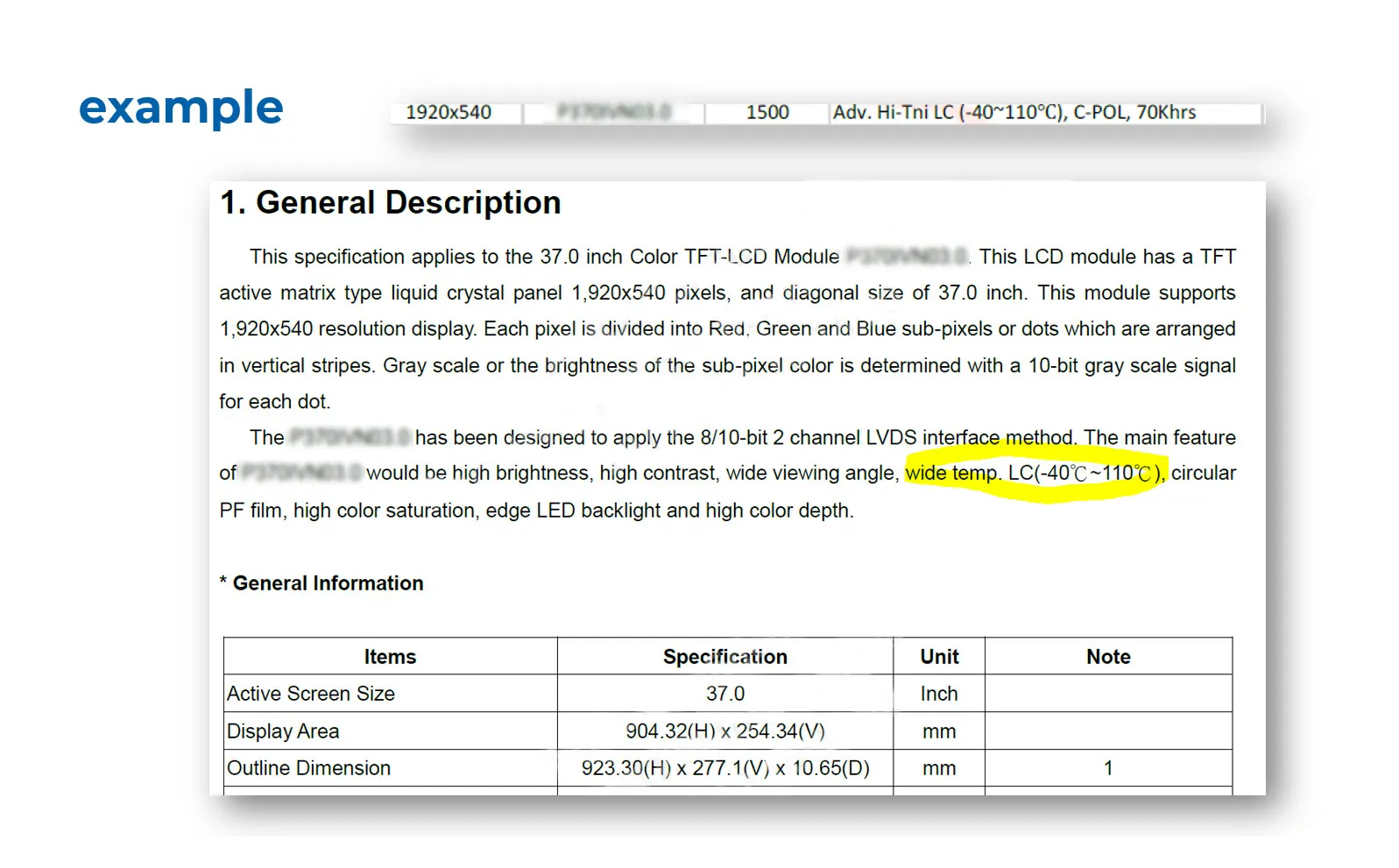

The picture above shows an example about Hi-Tni and outdoor displays. So, we have two kinds of cells, two liquid crystals that we can use. One operates in the temperature range from -20 up to +110 degrees and the other one operates in the temperature range from -40 up to +110

degrees. So, in this range we are safe, we can go very low with the temperature, and it will not become solid, and we can go very high with the temperature up to 110 degrees and it will not become isotropic.

Maybe you have even seen some displays that were used outdoors and sometimes they become black. We call that the blackening effect. If they become black, that means the crystals become isotropic. You can sometimes see that the part of the display is black or sometimes the whole display becomes black, depending on the temperature. The good thing is that it is not damaging the display, so once the temperature drops it goes back to the nematic phase and the display is working again, but in a high temperature you cannot see anything on the display, it is not working.

On the picture above, we have an example from a data sheet of a display with high temperatures. As we said it’s a liquid crystal from -40 to +110 degrees, and this is the latest technology. But you need to be careful! This is only about the surface of a display, the TFT glass itself. If we have the sunlight going to the display it can increase the temperature of the whole display as a module.

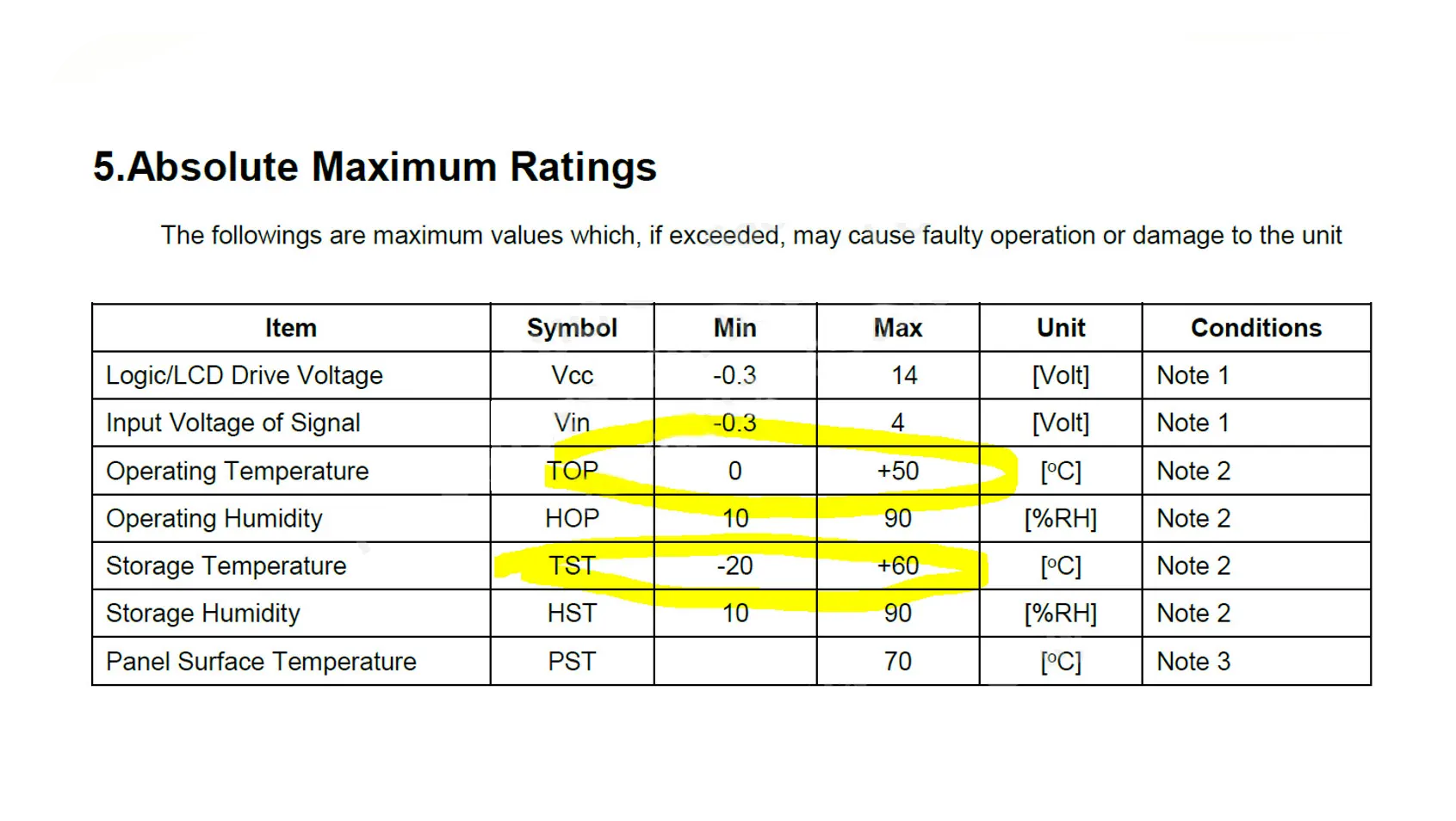

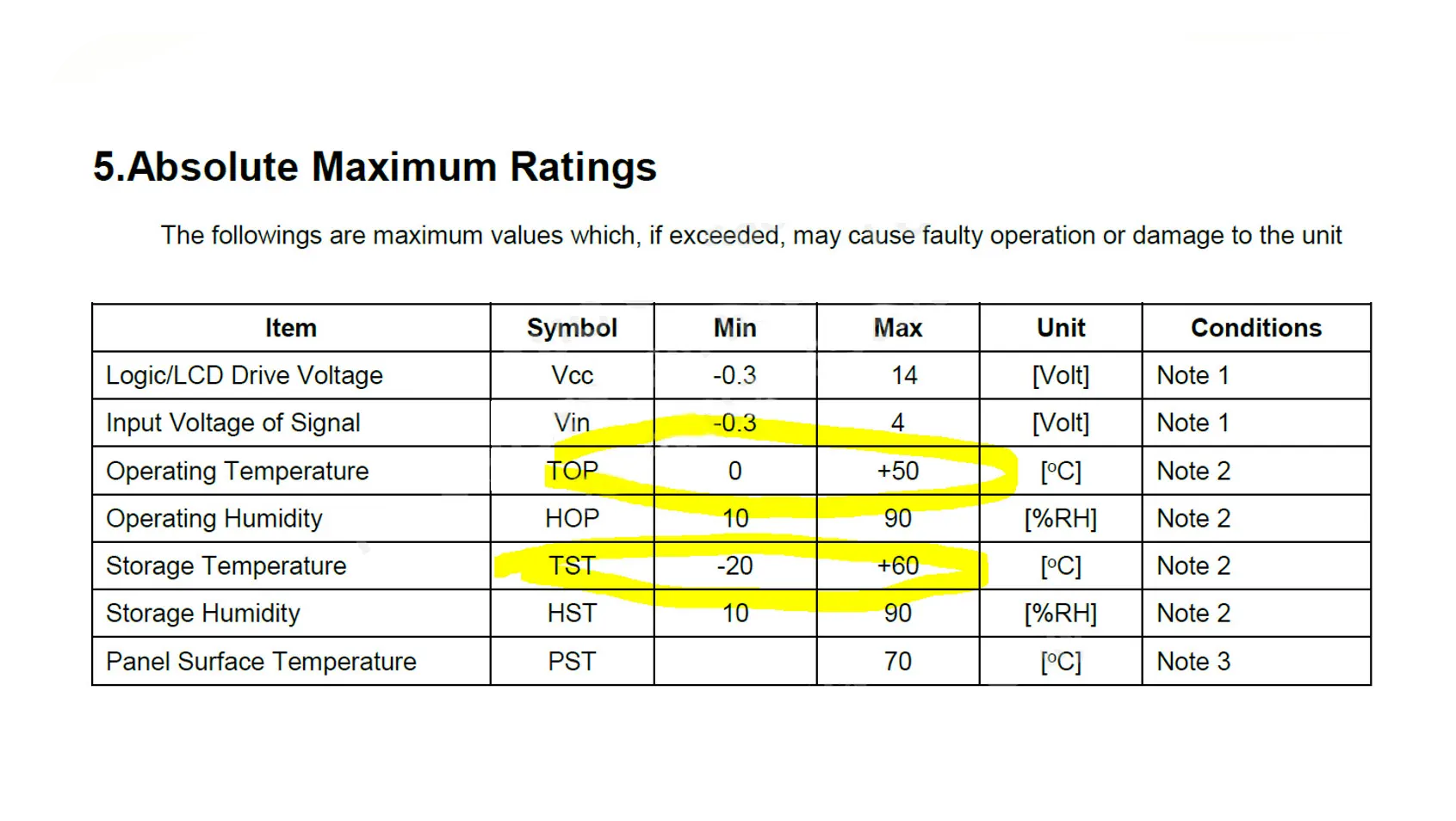

For the whole display module, the operating temperature range can be as low as 0 to +50 degrees or -20 to 70 degrees. We can have two operating temperatures, that means if we use the display outdoors, we are safe from the sunlight, the surface of the display can go very high, but we need to control the ambient temperature inside the display housing to not go too high. +50 or +70 will be maximum, usually we need fans to remove the heat from inside. Typically, in our case we have a computer inside and we have more devices that cannot work at high temperatures like +100 degrees, so we control the temperature anyway. So, the temperature cannot be too high inside and for sure cannot be that high as a liquid crystal itself can withstand, which is +110 degrees.

And that will be all in this article about contrast, brightness, and temperatures. Just one more thing: if you are planning on buying a laptop today, you can find brightness in the specification. Look at this number because this will determine how good your laptop will be outdoors. There are laptops on the market today that will have 1000 candelas or even more. If you are looking for a new device my recommendation also goes for mobile phones. Low brightness mobile phones can have 300, maybe 500 candelas, but nowadays the standard will be around 1000 candelas, but there are phones on the market that already have 1500 or even 1800 candelas. That means if you are in the sunlight you will still be able to see the image clearly. Of course, the battery will be drained faster, but sometimes it is not so important, maybe you just want to check something quickly, to read something and you want to have a clear image just be aware that this number is pretty important when you buy new devices!

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!