DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!

Description

BT817Q (EVE 4)

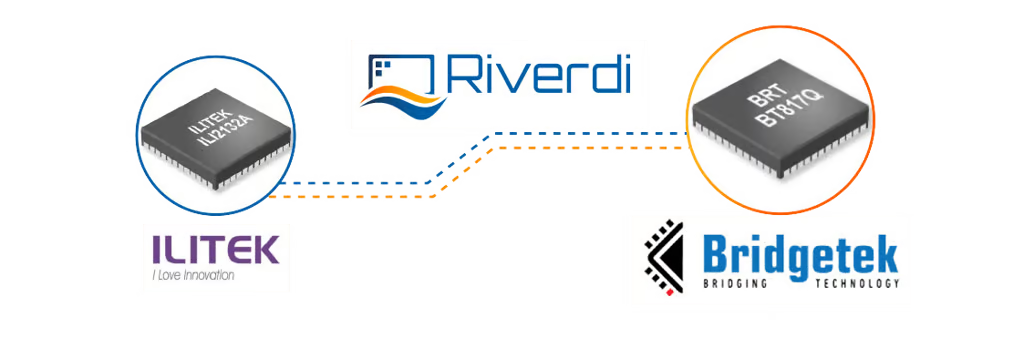

Revolutionary communication protocol

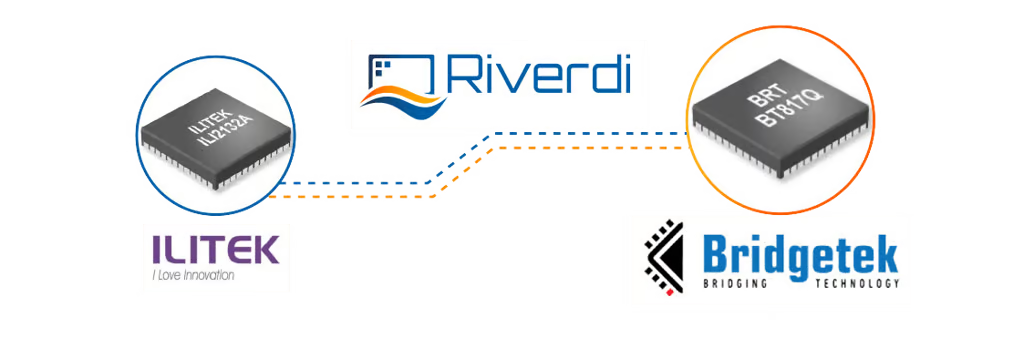

The close cooperation between Riverdi & ILITEK (touch panel controllers manufacturer) resulted in creation of a new communication protocol, which, for the first time in the world, has enabled for effective data interchange between graphics controller BT817Q built by Bridgetek and Capacitive Touch Panel controller ILI2132A built by ILITEK. ILI2132A is a truly industrial touch controller that allows Riverdi Intelligent Displays to be used in industrial, medical and even military applications.

A powerful graphics controller

If your application requires beautiful and sophisticated GUI built with simple software that can run on even smallest microcontroller with SPI/QSPI interface then the BT817Q series is for you.

The BT817Q controller on our display board is the most powerful member of advanced graphics controllers family, targeted at embedded applications for generating high-quality Human Machine Interfaces (HMIs).

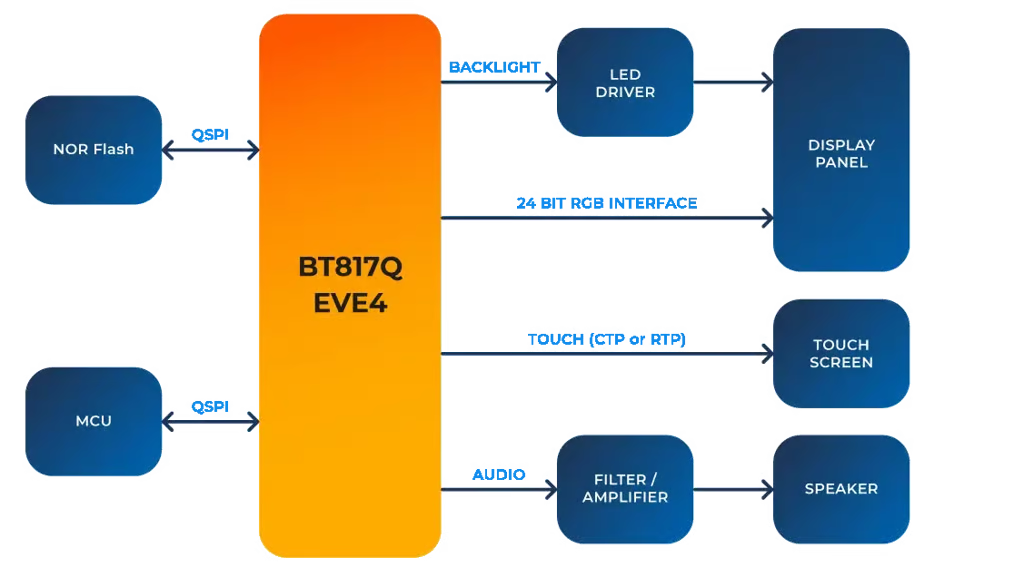

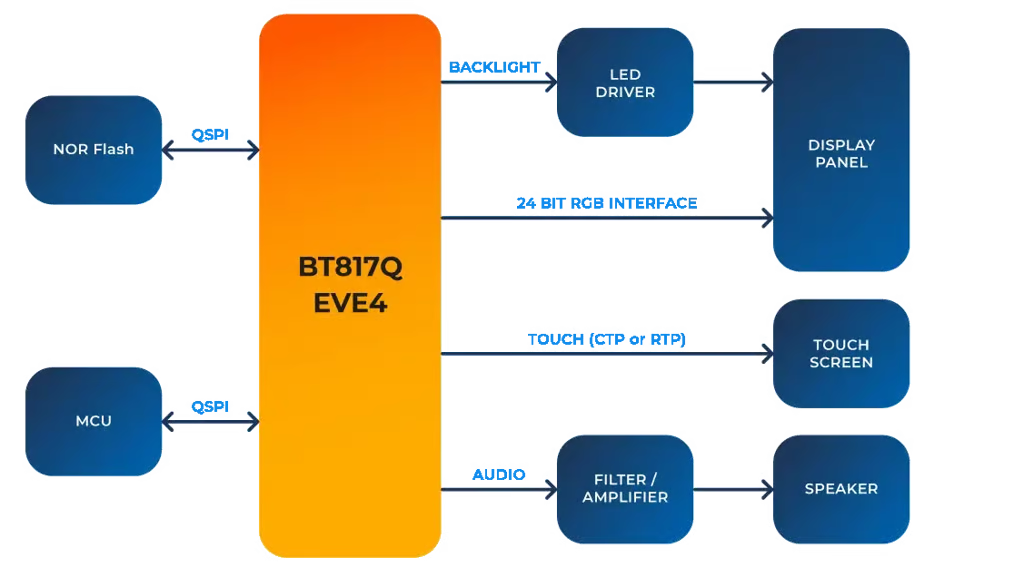

The picture below shows a block diagram of EVE (Embedded Video Engine) board and the interfaces of BT817Q controller to accompanying devices on the module.

Riverdi’s displays with BT817Q graphics controllers feature advanced EVE user interface that successfully combines the capacities of processing images, sound, and information from the touch panel.

EVE technology uses an object-oriented approach; this whole controller series is capable of simplifying the implementation of intelligent displays and shortening development time; Please see the datasheet.

Adaptive Scalable Texture Compression (ASTC)

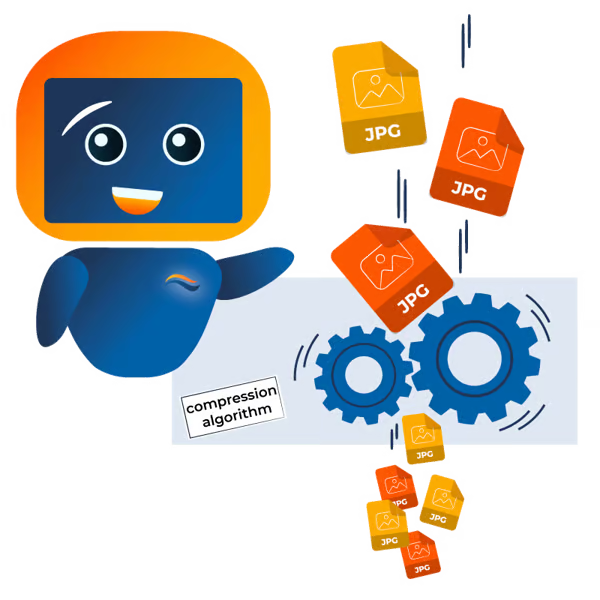

One of the most important advantages, in comparison with the first two EVE versions, is the support for the Adaptive Scalable Texture Compression (ASTC) algorithm, implemented first in the EVE3 and maintained in the EVE4 controller.

This means the image quality can be enhanced significantly without the need for greater bandwidth. In certain situations, the compression algorithm allows for smaller graphic files to use compression without losing picture quality. This, in turn, saves up significant areas of memory space, required in EVE1 and EVE2 controllers by larger font files and data-heavy images.

Further memory management and system resource improvements have been applied to the EVE4 controller thanks to the presence of a dedicated QSPI port for connection of an external flash memory chip, implemented first in the EVE3.

See the datasheet for further information.

The Riverdi EVE4 boards are equipped with a separate flash memory chip. It is connected via a dedicated QSPI interface to the BT817Q controller. This allows the management of the memory content from the controller but such management engages the controller’s time and resources.

The purpose of adding this chip to the board is storing pictures that will be displayed during a standard operation of the module. Calculations with real JPEG files with appropriate resolutions indicate that flash memory chip used in the EVE4 board is capable of holding up to 270 JPEG files for 3.5” displays and up to 110 JPEG files for 10.1” displays.

Calculations presented here must be done again for specific JPEG files because of compression method used in the JPEG standard. In other words, the size of a certain picture (measured in kilobytes) saved in the JPEG standard depends not only on the resolution, but also on the content shown (colors palette, contrast etc.).

Dedicated fast-programming port for built-in flash memory

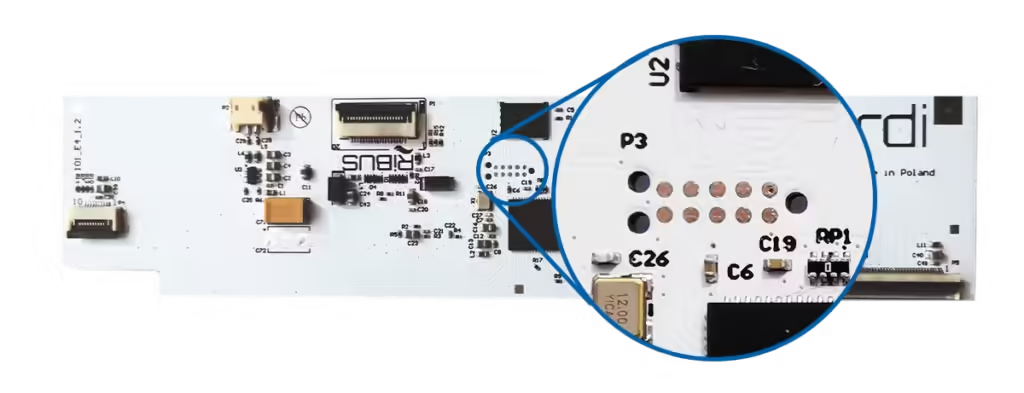

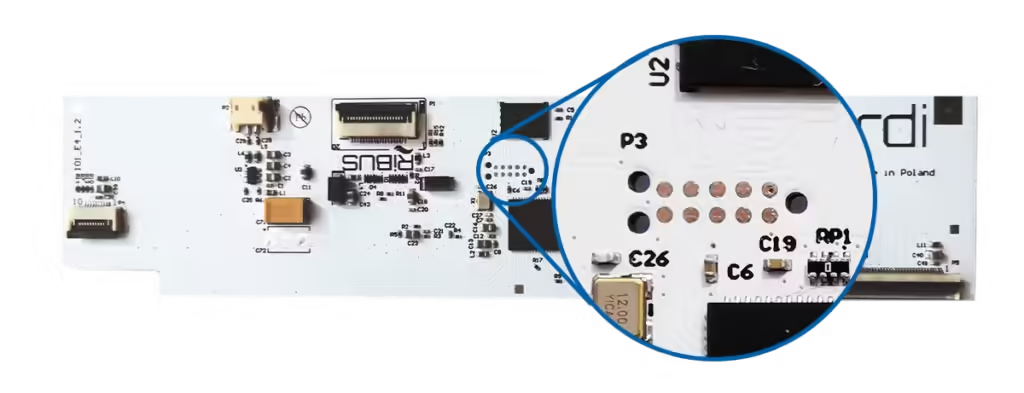

Engineers at Riverdi decided to place an additional, dedicated port on the EVE4 board for fast programming (writing the content) flash memory chip from an external source.

This process is planned to be used during production so the end customer will be able to order pre-programmed EVE4 boards with graphic content of their own choice. The process requires a special cable with a connector compatible with the fast programming port. The below photo shows the EVE4 board with fast-programming port (P3).

EVE4 boards are also equipped with an on-board audio amplifier and the pin no. 10 in RiBUS connector which allows for bidirectional transmission of the acoustic signals, as opposed to EVE3 standard. Thanks to the hardware development, EVE4 boards allow for mixing of two audio signals, one from the BT817Q controller (local audio signal) with the second one from the host (external audio signal). EVE4 boards have separate connector used to attach the loudspeaker to the on-board audio amplifier output.

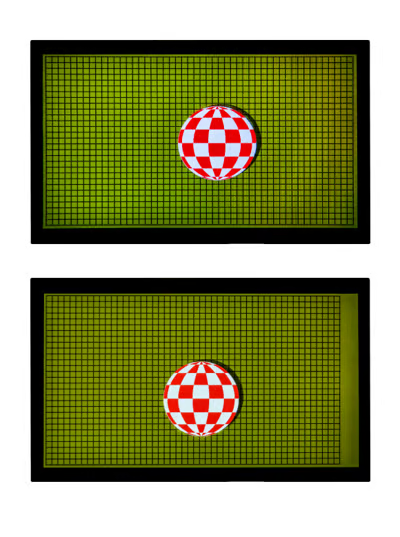

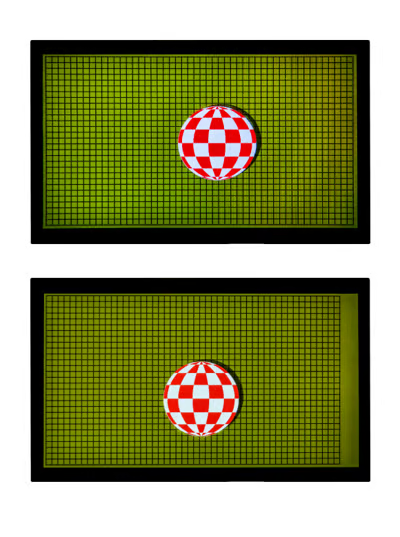

Non-square pixel correction

Another feature implemented to EVE4 graphics controller in the 7” displays for the first time is the ‘non-square pixel’ algorithm. This feature frees the end user’s programmers from the burden of re-scaling the pictures due to non-square pixels and, in consequence, reduces the time necessary for adapting the 7” EVE4-based modules to operate in its final environment, thus shortening the customer’s development procedures. It gives Riverdi’s 7” modules a competitive advantage as they require significantly less time to be applied in the final environment. We have captured the testing of picture. The photo on top shows picture without correction and the photo on the bottom shows picture with correction by the non-square pixel algorithm.

The ball in the photo on top is not a circle but an ellipse with axis proportion 1.043 (horizontal) to 1.000 (vertical). The ball in the bottom photo is a circle.

2x Pixel Mode

2x Pixel mode is an internal feature which has been added to the EVE4 devices, in order to support higher PCLK rates. In EVE4, PCLK can be up to 2x system clock frequency. When the PCLK frequency is greater than or equal to the system clock frequency, 2x Pixel Mode should be enabled and the Graphics Engine core sends 2 pixels per clock to the EXTSYNC block instead of one.

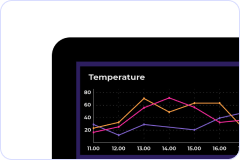

High brightness, IPS TFT

Typical surface luminance for a high brightness, IPS TFT displays is 800 up to 1000 cd/m² which means it is very bright even outdoors. The full viewing angles allow the user to interact with the display in a natural and intuitive way from every side. Please see the datasheet for more features.

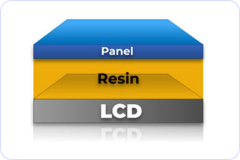

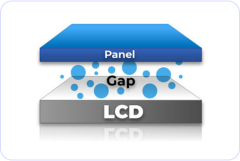

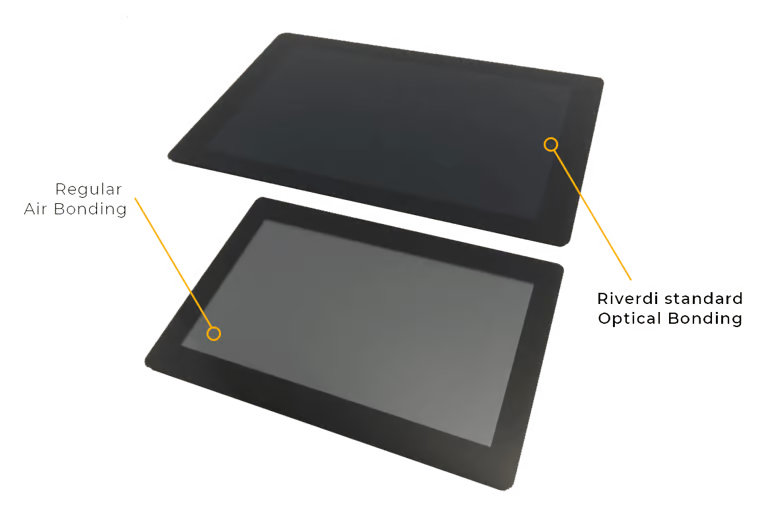

Optical / Air Bonding

Enhancing the optical performance of your display

Optical bonding is a process of affixing the touch panel (or just the protective glass) to the display using a liquid adhesive, gel or dry (film). In general, this process improves the parameters of the module – the optical performance, as well as durability.

The air-gap is the reason for the phenomena of reflection of sunlight. So, when the display is off, the Visual Area (V.A) is never black – it is gray.

When removing the air gaps, we reduce the number of internal reflecting surfaces, which increase of optical performance. This phenomenon improves readability, by reducing the reflection and correct contrast.

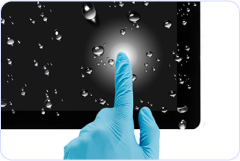

Industrial Touch Screen

Reacts to the slightest touch

The PCAP (Projected Capacity touch panel) is classified as ‘industrial’ (as opposed to ‘consumer’) when it is able to operate correctly in more demanding, harsh conditions (i.e. disturbing electromagnetic fields around causing interferences with panel controller, water droplets present in the surrounding area also on panel glass), and react properly when touched by hands in gloves. It can be tuned at the factory, detect touch through thicker glass layers than consumer panels (6mm thick glass layer was tested with success in the Riverdi lab) and it uses an industrial grade chip controller. Such controllers have industrial manufacturer’s guidelines implemented and are guaranteed to be manufactured typically from 10 to 15 years.

Main features:

- ILITEK Touch IC-ILI2132A, with 10 years guaranteed availability

- USB/I²C interface

- Supports cover glass thickness up to 8 mm*

- Supports thick gloves operation (i.e. double gloves, tactical gloves)*

- Working with water on the surface

- Multi-touch, up to 10 points

- Great EMC, RS (radiated susceptibility) and CS (conductive susceptibility) performance

*Riverdi is skilled to adjust parameters up to specific needs (thicker gloves, thicker glass)

Traditional shape with modern functionality

aTouch was designed to provide the functionality of a modern Projected Capacitive Touch panel in a traditional shape and size perfect for an upgrade of an older device. Thanks to the absolute flat design and multi-touch feature, it will significantly raise the value of any project. It features chemically strengthened glass, which has increased durability, thanks to the process of ion-exchange. They are easy to assemble, easy to clean and easy to implement into your design.

Newly built devices most often use the uxTouch panel which is stuck to the outside of the device and is slightly larger than the display – it looks nice and modern. However, in older devices that only need an upgrade, the panel needs to be the same size as the display. Thus, there are many customers who require the solution provided by aTouch in order to mount the display from the inside into the classic hole.

Customized displays

You can customize displays in many different ways.

- Change the color, shape, and size of the cover glass

- Have your logo printed on the cover glass (or any other graphics you might need)

- Add a different interface

- Enhance the brightness of the screen

- Change the thickness of the cover lens for the CTP

- Choose a different viewing angle of the display

- Change the pinout

- Request different gasket assembly

As you can see the possibilities are endless. All you need to do is choose.

We will help you to get the perfect tailor-made product.