When designing displays for challenging lighting environments, engineers often encounter the terms anti-glare and anti-reflective coatings. While both technologies address visibility issues caused by ambient light, they function through fundamentally different mechanisms and deliver distinct performance characteristics. Understanding these differences is decisive for selecting the optimal solution for your particular application requirements.

Anti-glare vs. anti-reflective coatings—the basics

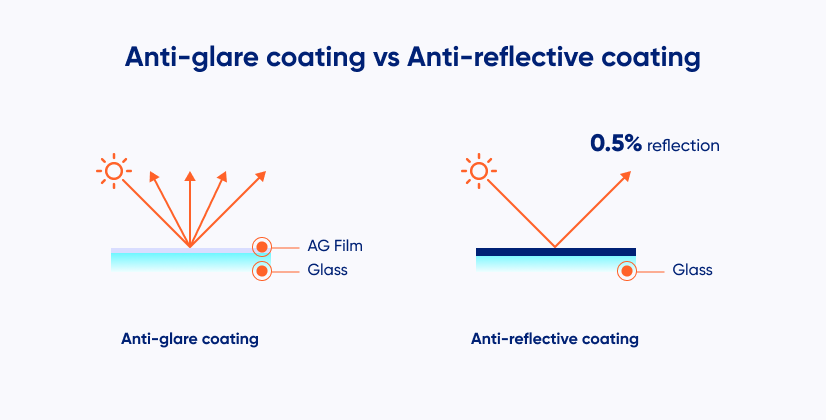

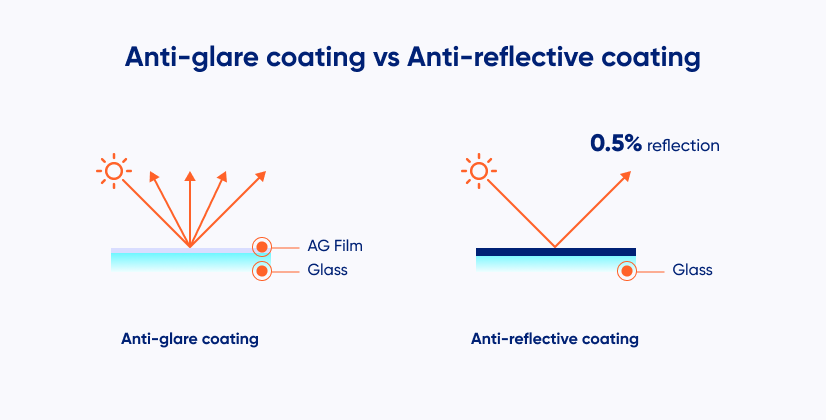

Anti-glare and anti-reflective treatments serve the same primary objective: improving display readability in bright environments. The real insight comes from examining how each achieves that goal. Anti-glare coatings work by scattering reflected light in multiple directions, reducing the perceived intensity of reflections without actually decreasing the total amount of reflected light. Anti-reflective coatings, conversely, minimize the quantity of light reflected from the surface through optical interference principles.

This distinction becomes crucial when calculating effective contrast ratios (ECR) for outdoor or high-brightness applications. While both treatments improve readability, their impact on image quality, cost, and manufacturing complexity varies considerably.

What is reflection and how to reduce it?

Light reflection occurs when electromagnetic radiation encounters the boundary between two materials with different refractive indices. For standard glass surfaces, approximately 4-5% of incident light reflects at each interface. In display applications with protective glass, this creates multiple reflection points: air-to-glass, glass-to-air gap, and air-to-display surface.

These reflections add unwanted brightness to both the bright and dark areas of displayed content, significantly reducing effective contrast ratios. In outdoor environments with 10,000 candelas of ambient illumination, even a 4.5% reflection rate can reduce a display’s contrast from 400:1 to approximately 4-5:1—approaching the 5:1 threshold for acceptable readability.

Differences between anti-glare and anti-reflective coatings

The fundamental distinction lies in optical behavior. Anti-glare surfaces (AG) feature microscopic texturing that creates diffused reflections, spreading the same amount of reflected light across wider angles. This makes reflections less perceptible to viewers positioned directly in front of the display.

Anti-reflective coatings (AR) employ thin-film interference to cancel specific wavelengths of reflected light. Multi-layer AR coatings can reduce reflectance from 8% (both glass surfaces) to less than 0.5%, while maintaining over 99% light transmission. This represents a genuine reduction in reflected light energy, not just its redistribution.

Anti-glare coating—how it works, pros & cons

Anti-glare coatings create a controlled roughness on the glass surface through chemical etching or particle deposition. This microscopic texture breaks up specular (mirror-like) reflections into diffuse patterns. The human eye perceives this scattered light as less intense since only a fraction reaches the viewing angle.

Its primary advantage is cost-effectiveness combined with substantial glare reduction in typical indoor and moderate outdoor environments. Manufacturing processes are well-established and can be applied to various substrate materials without complex equipment.

However, anti-glare treatments come with trade-offs. The same diffusion mechanism that reduces glare also affects light emanating from the display itself. This results in image softening, reduced apparent resolution, and decreased color saturation. The textured surface also attracts contaminants more readily, complicating cleaning procedures—particularly important for medical or food service applications requiring frequent disinfection.

Anti-reflective coating—how it works, pros & cons

Anti-reflective layers function through destructive interference of light waves. Multi-layer dielectric films with precisely controlled thicknesses and refractive indices are deposited onto the glass surface. When light reflects from the coating-air interface and the coating-glass interface, these reflections cancel each other at specific wavelengths.

Advanced AR coatings achieve remarkable performance metrics: reflectance below 0.5% and transmission exceeding 99%. This translates directly into improved effective contrast ratios without compromising image quality. The smooth surface maintains the display’s original resolution and color characteristics while being easier to clean than textured anti-glare surfaces.

The primary drawback is manufacturing complexity and cost. Vacuum deposition processes require sophisticated equipment and precise environmental control. Additionally, AR coatings can be more susceptible to damage from abrasion, though protective hard coatings mitigate this concern effectively.

Comparison and applications

Impact on image quality and readability

For applications prioritizing image fidelity, anti-reflective coatings provide superior performance. Medical displays, high-resolution industrial monitors, and precision instruments benefit from AR treatment’s ability to maintain sharp imagery while minimizing reflections.

Anti-glare coatings are the best solution in applications where moderate image degradation is acceptable in exchange for cost savings and reliable glare reduction. Point-of-sale terminals, outdoor signage, and consumer electronics often utilize anti-glare treatments effectively.

In high-res displays above 300 PPI, anti-glare structures must be increasingly fine to avoid visible interference patterns. At these resolutions, the distinction between anti-glare and untreated surfaces becomes minimal, making anti-reflective coatings more practical.

Costs and recommendations for different projects

Anti-glare treatments typically cost 30-50% less than equivalent anti-reflective solutions, making them attractive for volume applications with moderate performance requirements. The simpler manufacturing process also enables shorter lead times and greater supplier flexibility.

Anti-reflective coatings justify their higher cost in demanding applications: medical equipment, public terminals, EV chargers, or industrial equipment exposed to direct sunlight, automotive dashboards,, and military systems where maximum readability is non-negotiable. When combined with optical bonding techniques that eliminate air gaps, AR coatings can achieve effective contrast ratios above 15:1 even in challenging outdoor environments.

For projects requiring specific substrate properties like impact resistance or flame retardancy, coating compatibility becomes a selection factor. Not all surface treatments can be applied to specialized materials, potentially limiting options. All in all, the decision ultimately depends on balancing performance requirements against budget constraints. In applications where display readability directly impacts safety or operational efficiency, the premium for anti-reflective coatings often proves worthwhile. For general-purpose applications with controlled lighting conditions, anti-glare treatments provide adequate performance at lower cost.

Need expert guidance in balancing available coatings with your upcoming project?

Contact our engineering team to choose the best industrial-grade standard and customized solutions.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!