- Basic principles of VFD Technology

- Key components of a VFD Display

- How VFD displays produce bright and clear images

- The role of phosphor in Vacuum Fluorescent Displays

- Advantages of using VFDs over other technologies

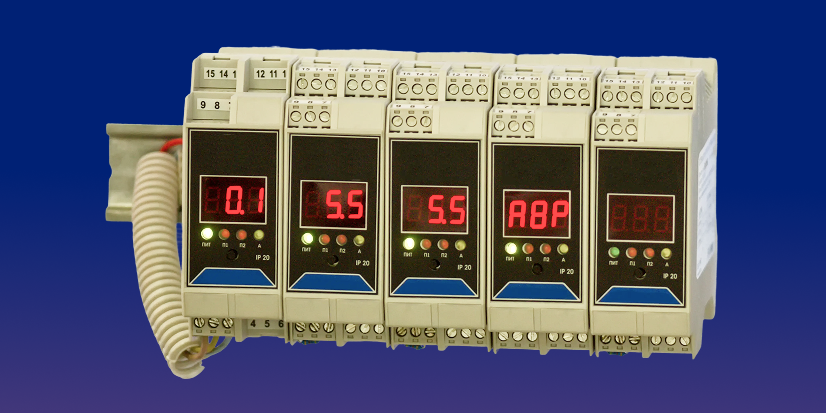

- Common applications of Vacuum Fluorescent Display Technology

- Frequently Asked Questions about Vacuum Fluorescent Displays (VFD)

In a world where displays evolve across generations, certain technologies endure because they fulfill a promise of reliability. The Vacuum Fluorescent Display (VFD) is one of them. This article explores the functionality of VFDs—explaining how these displays work, why they are still chosen in key industrial applications, and where their simple, traditional architecture must give way to modern TFT IPS panels.

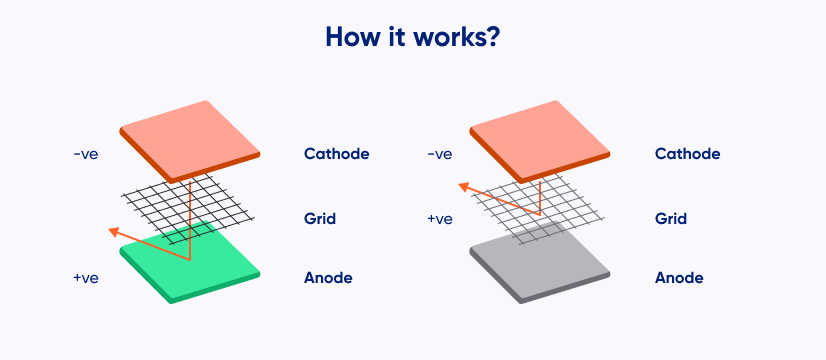

Basic principles of VFD Technology

The operation is based on a simple but precise mechanism: a heated filament emits electrons, which travel through a controlled vacuum and strike a phosphor layer that immediately begins to glow.

The entire structure is enclosed in a vacuum-sealed glass envelope, which keeps the parameters stable even after many years of use.

Key components of a VFD Display

Inside the display, there are only three active elements. The heated filament (cathode) works as the source of electrons. The control grid is a mesh electrode that determines which segments light up by allowing or blocking the electron flow to the anode. Phosphor on the anodes is responsible for light emission.

How VFD displays produce bright and clear images

Because phosphor in a VFD emits light directly, without any backlight, each character appears with high intensity and is readable from almost any angle. The high brightness comes not from an LED backlight but from direct excitation of the material by electron emission. This provides excellent contrast and maintains readability even at elevated temperatures.

Today, similar stability—combined with a much wider functional scope—is delivered by TFT IPS panels, which Riverdi uses in most new designs. Proper polarization and high luminance ensure comparable clarity while adding full graphics, color, and high resolution.

The role of phosphor in Vacuum Fluorescent Displays

The phosphor type directly defines the emission color (green, blue, red, or white). Its quality affects brightness and long-term lifetime. It also contributes to the wide viewing angle, high contrast, and overall sharpness of the displayed characters.

Advantages of using VFDs over other technologies

Despite their age, VFDs still have their place. Their unmatched brightness, wide viewing angles, and durability in harsh conditions make them a reliable choice for many industrial devices. If a project requires a simple, unambiguous readout, operates at elevated temperatures, or runs in environments that quickly degrade standard LCDs, a VFD remains a sensible and stable option.

However, once you need graphics, icons, a touch interface, or animation, phosphor-based designs give way to TFT IPS panels — especially those with optional uxTouch or aTouch, which Riverdi engineers specifically for industrial environments.

Common applications of Vacuum Fluorescent Display Technology

Today, VFDs are mostly used where reliability and predictability matter:

- simple operator panels,

- household appliances exposed to high temperatures,

- measurement instruments,

- POS terminals.

Frequently Asked Questions about Vacuum Fluorescent Displays (VFD)

What are the environmental impacts of using VFD displays?

VFDs do not contain mercury or other toxic substances, and their long lifespan reduces the amount of electronic waste ending up in disposal.

How does the brightness of a VFD display compare to other display technologies?

VFDs are very bright for a segmented-display technology. However, modern high-luminance TFT IPS panels can surpass them in readability while also offering full graphics and color.

Can VFD displays be used in outdoor applications?

Yes—as long as they are protected from rain and moisture. They handle temperature variations, vibration and harsh industrial environments better than many traditional LCDs.

What maintenance is required for VFD displays?

Periodic cleaning is usually sufficient. It’s only important to avoid displaying the same static characters for months at a time.

Are VFD displays susceptible to burn-in?

Yes, although less than CRTs or OLEDs. Content rotation or automatic dimming effectively prevents burn-in.

Need help choosing the right display technology? Contact our engineering team.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!