Walk into any decent electronics store and you’ll notice something striking about premium screens—they practically glow with life. That vibrant quality you’re seeing? There’s a good chance it’s AMOLED technology at work. Take a look outside the electronics store and it wouldn’t be an exaggeration to say that this technology is omnipresent. And you probably use it every day on your smartphone, tablet, laptop, and even TV. But what makes these displays so compelling goes deeper than just their shine-bright-like-a-diamond performance.

How does AMOLED work?

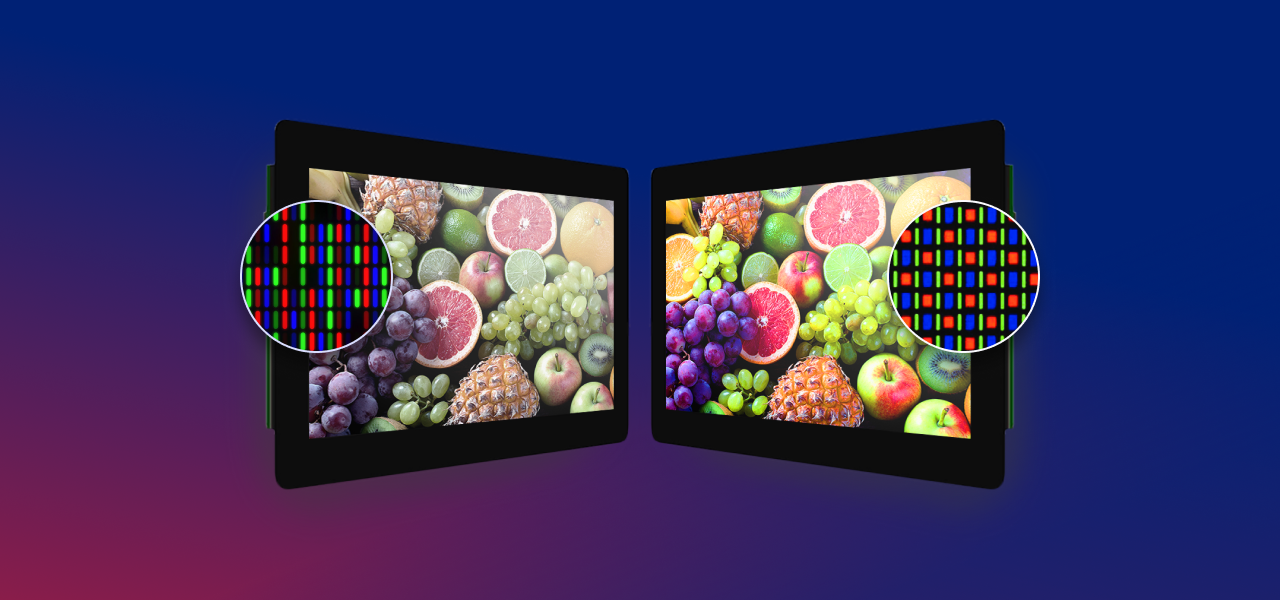

AMOLED displays generate their own illumination at the pixel level, unlike LCD displays that act like sophisticated light filters. Think of LCD as holding colored glass up to a flashlight, while AMOLED is like having millions of tiny, controllable light bulbs, each producing its own perfect color and brightness independently.

This is why AMOLED, again unlike LCDs, doesn’t require a backlight. All the physical and engineering “magic” happens here between two conductors—a cathode and an anode—where the OLED material is deposited on a substrate. When current flows through it, from the cathode to the anode, it emits light.

But what when an AMOLED pixel needs to display black? It simply turns off completely. No light leakage, no grayish “black”—just pure darkness. This results in contrast ratios exceeding 100,000:1. And the latest Dynamic AMOLED 2X screens push that even further, reaching an incredible 2,000,000:1.

What is an AMOLED screen?

AMOLED as a technology can be a great example that “organic” means exceptional quality not only in agriculture and food. All because this type of screen combines organic chemistry with precision electronics. It’s built around organic compounds, commonly including polyfluorene and anthracene, that emit light when electricity passes through them. Thus it can produce specific colors by itself with remarkable efficiency guaranteeing the display of 16.7 million colors. This goes far beyond the perception capabilities of the average human eye, which can distinguish 160 colors and 600,000 shades.

Underneath AMOLED’s organic layers there is the control system—each pixel has its own thin-film transistor (TFT) acting like a microscopic switch and memory cell, enabling precise control over brightness and color for high-resolution, stable images.

Diagram of AMOLED with a grid of TFT transistors

What does AMOLED mean

AMOLED stands for Active-Matrix Organic Light-Emitting Diode:

Active-Matrix: Each pixel gets independent control through its dedicated transistor, enabling larger displays and faster response times.

Organic: Light-emitting materials are carbon-based (not silicone-based like in LED) compounds, precisely tuned to emit specific wavelengths for pure, saturated colors.

Light-Emitting Diode: Each pixel functions as a diode, emitting photons directly without complex backlight systems.

What are the advantages of AMOLED displays?

Black is not only synonymous with classics and elegance, but also a kind of litmus test in terms of image reproduction quality. One of the main aesthetic advantages of AMOLED pixels is that they produce true and deep blacks. And they do so simply when they are off, making critical alerts achieve maximum visibility against dark backgrounds. In general, AMOLED technology offers the widest gamut color on the market, with vibrant colors and contrast, unrivaled by a typical TFT.

But let’s look at the benefits of this technology holistically:

Power efficiency with dark content: Unlike LCD’s constant backlight power, AMOLED only consumes power for illuminated pixels—significant savings with dark interfaces.

Lightning-fast response: Pixels switch in less than a millisecond, which is crucial for responsive touch interfaces and smooth video content.

Exceptional viewing angles: Self-emitting pixels provide nearly 180-degree viewing with minimal color shift—invaluable in collaborative environments.

Less than 1mm panels: Eliminating the backlight allows for lightweight, extremely thin and flexible industrial screens including rollable or foldable displays.

Super AMOLED as a more advanced version: Integrating touch-sensors directly into the screen—removing the separate touch layer improves even more brightness and outdoor visibility, and reduces power consumption.

What are some drawbacks of AMOLED displays?

Apart from consumer products, AMOLED technology is not widely used in industrial applications—still growing and just beginning to mature, partially because of the patents. Apart from that, there are only a few minor disadvantages:

Higher power with bright content: Full-screen white background can sometimes consume more power than the TFT display.

Cost considerations: Manufacturing remains more complex and expensive than LCD production but it can be optimalized with volume tiers.

AMOLED vs PMOLED

PMOLED (Passive Matrix OLED) uses simpler construction where pixels are controlled by intersecting rows and columns. It works for small displays (generally under 3 inches) like fitness trackers and small wearable electronic gadgets but becomes dim and power-hungry as resolution and size increases.

AMOLED‘s active matrix gives each pixel its own storage element. Once set, pixels maintain their state until refresh, enabling larger displays, higher resolutions, and better power efficiency.

This means that an AMOLED screen requires a lot of information to be sent to usually display a HQ colorful video. Its Active Matrix will work perfectly with interfaces like MIPI, DSI or RGB for some industrial use cases. Contrary to this, sending simple information about switching the pixel on and off and occasionally the grayscale is the case of the Passive Matrix OLED display. Here will fit I2C, SPI and old parallels as general purpose interfaces that require a memory in the display itself.

AMOLED for industrial applications

Crisp and customizable graphical HMIs enabled by AMOLED can be a real gamechanger where high quality of display performance may correlate with the specialist’s performance:

Control rooms: Deep blacks maintain operator alertness while vibrant colors ensure critical alerts capture attention. Wide viewing angles support collaborative monitoring.

Handheld devices: Power efficiency with dark interfaces extends battery life. Fast response times work well with gloved operation.

Medical imaging: Exceptional contrast reveals subtle details, though color accuracy demands careful calibration.

Digital signage: Creates stunning visual impact for dynamic content, but static elements require careful design to prevent burn-in.

Success lies in leveraging AMOLED’s strengths while mitigating limitations through smart interface design. Which is why Riverdi doesn’t offer AMOLED displays as standard models. In a close partnership with our clients we develop custom modules for each project.

Contact our engineering team to work on custom display solution in your industrial application. Make it shine among the others.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!