Touchscreens are part of our everyday lives — found in smartphones, ATMs, cars, and self-service kiosks. As is often the case in the tech world, behind every intuitive interface lies advanced engineering and a variety of competing solutions. In this article, we’ll explore the most important types in use today, and the working principles behind each — essential knowledge for choosing the right solution for any application.

What is a touchscreen?

A touchscreen is an interface that combines the functions of a display and an input device. It enables interaction through touch – replacing the need for a keyboard or mouse – by registering specific contact points on its surface. Depending on the underlying technology, the screen can detect pressure, disruptions in an electrostatic field, breaks in a light beam, or the damping of acoustic waves. The key element is the detection layer – it translates a simple finger touch into a signal the system can understand.

The history of touchscreens

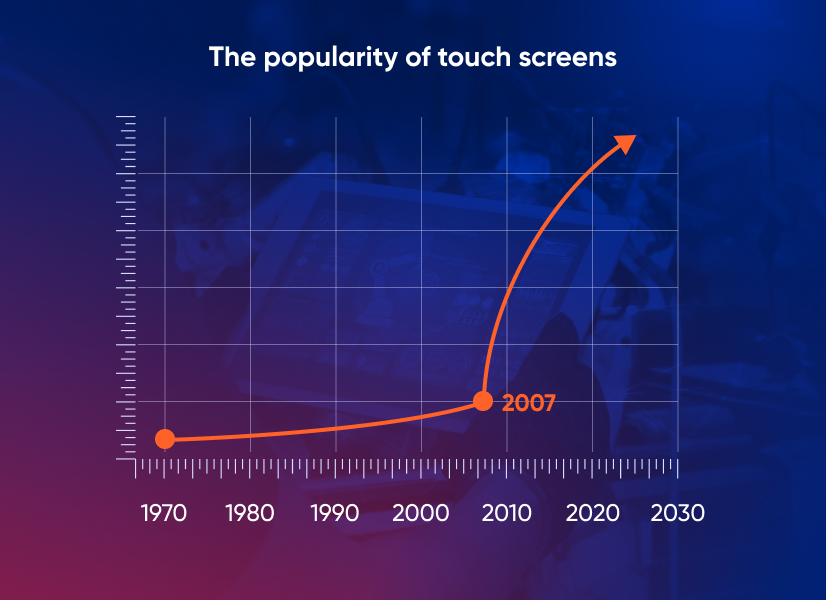

The first touchscreen concepts date back to the 1960s, with E.A. Johnson’s pioneering work based on capacitive sensing. In 1974, Dr. G. Samuel Hurst developed resistive touch technology, which was soon adopted in industrial terminals. Over the following decades, touchscreens made their way into medical equipment, ATMs, and later into PDAs and early smartphones.

The breakthrough came in 2007, when the iPhone popularized projected capacitive touch – a highly responsive, multi-touch technology that enabled gesture-based interfaces. From that moment on, touchscreens became ubiquitous.

How do touchscreens work?

At the core of any touchscreen is the process of detecting a touch point and translating it into X-Y coordinates. These coordinates are sent to a controller that interprets the signal and communicates with the operating system. The major differences between technologies lie in how the touch is detected: some measure pressure, others detect changes in electrostatic fields, while others use sound waves or light. All of them share the need for signal processing circuits – often with noise filtering and interpolation – to ensure precise and fast response from the interface.

Main types of touchscreens

There are many other types of touchscreen technologies, but these six are the most commonly used in commercial and industrial applications.

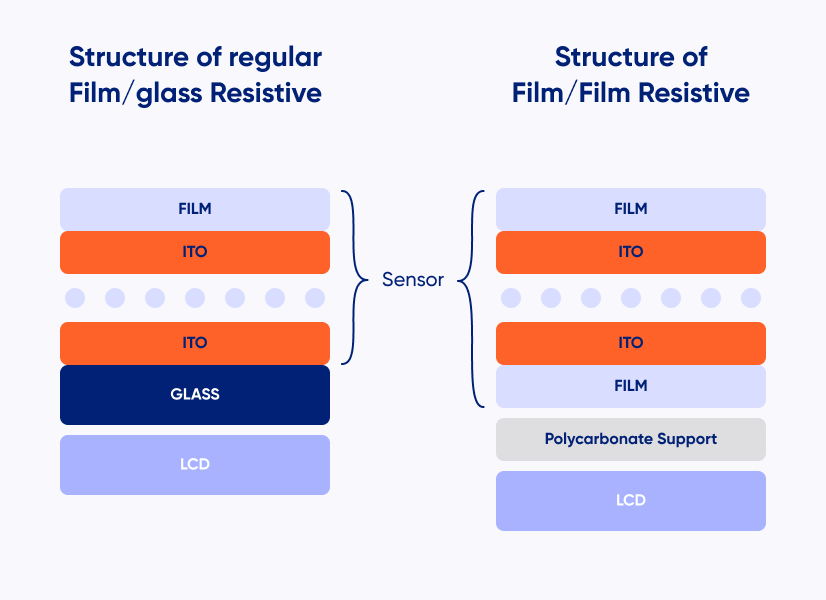

Resistive touchscreens

An older but still relevant technology, resistive touchscreens consist of two flexible conductive layers (usually coated with ITO – Indium Tin Oxide) separated by a tiny gap. Pressing the screen causes the layers to make contact, closing the circuit. The system measures voltage changes to locate the touch point. These screens work with any object – no need for skin conductivity – and are resistant to dirt and dust. However, they don’t support multi-touch and have limited optical clarity.

Capacitive touchscreens

In capacitive touchscreens, touch is detected as a change in electrostatic capacitance. The screen surface holds a small electrical charge within a transparent conductive layer. A human finger – acting as a conductor – alters the electric field. Sensors, typically placed at the corners, analyze the change in potential and locate the touch. These screens offer better clarity, faster response, and higher sensitivity than resistive ones, but traditionally don’t work with gloves or non-conductive styluses.

Projected capacitive (PCAP) touchscreens

This advanced capacitive variant uses a matrix of electrodes arranged in X-Y grids. Each intersection forms an individual sensing node. PCap enables precise multi-touch recognition, gesture input, and even operation through thick protective glass. These screens are scratch-resistant, dirt-resistant, and very responsive, but they are more expensive to manufacture and more complex to integrate.

Infrared (IR) touchscreens

Instead of physical working layers, IR touchscreens rely on a grid of invisible infrared beams emitted and received by LEDs and photodetectors placed around the display. When a finger interrupts these beams, the system registers a touch. IR screens are highly durable, support input from any object, and offer excellent optical clarity. Their main drawbacks are sensitivity to environmental interference.

Surface acoustic wave (SAW) touchscreens

SAW technology uses ultrasonic waves that travel across the surface of a glass panel. A touch dampens the wave, and sensors measure the time delay and amplitude changes to determine coordinates. SAW touchscreens offer high resolution and optical transparency, as they don’t require additional display layers. However, they are vulnerable to contaminants.

Optical imaging touchscreens

These systems rely on image processing. Cameras or photodetectors placed in the corners of the screen capture changes in light – such as a finger’s shadow – and software algorithms calculate the touch point. This approach is easily scalable and often used in large-format displays, interactive whiteboards, and tabletop touch systems.

The future of touchscreen technology – what can we expect?

The future promises not only greater precision and durability but also entirely new dimensions of interaction. Engineers are working on next-generation haptics that simulate textures, clicks, and resistance under your fingertips. Flexible touchscreens for foldable devices are also gaining traction – requiring bendable sensing layers and controllers that can withstand mechanical stress.

Next-gen interfaces will detect gestures without physical contact – using radar or 3D sensors – and recognize varying pressure levels to adapt responses accordingly. AI will play a role in dynamic sensitivity calibration based on the user’s environment. Touchscreens will evolve from mere tools into intelligent partners in interaction – seamlessly integrated into every aspect of our lives.

Not sure which touch technology is right for your application?

From capacitive to resistive – the right choice depends on your environment, usage, and performance needs.

Contact our engineering team. We’ll help you select the optimal touch solution for your application and guide you through integration for the best results.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!