When designing a device display, you face a key choice: transmissive or transflective LCD. Both use liquid crystals and polarizers, but they handle light sources very differently. In practical terms, your decision impacts how well the screen performs in sunlight, its power consumption, and its overall reliability in harsh industrial settings.

This article explains how both technologies function, outlines their limitations, and details the best use cases for each in industrial projects.

When to choose a transmissive LCD display?

A transmissive LCD is the industry standard—familiar from monitors, smartphones, and laptops. It’s the technology users associate with high contrast, saturated colors, and predictable behavior under controlled lighting conditions.

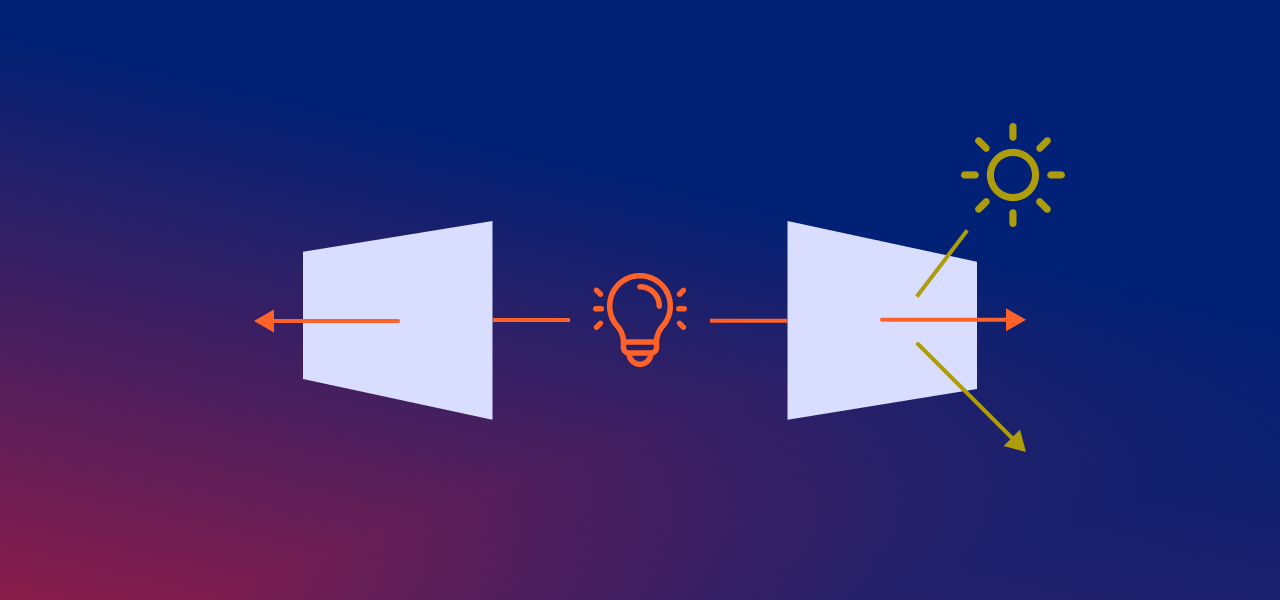

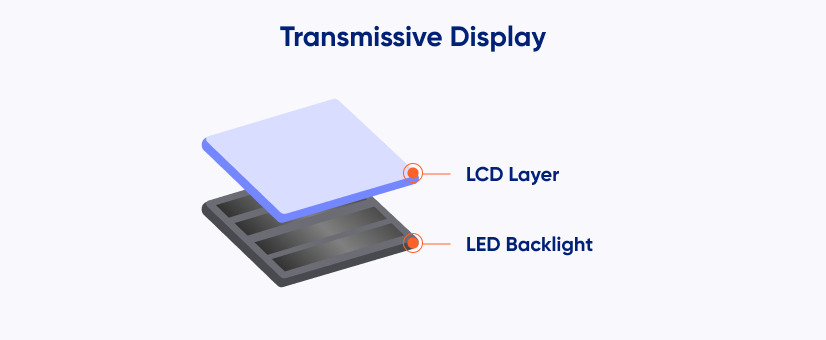

How transmissive technology works (Backlight-Dependent)

In transmissive panels, all visibility depends on the LED backlight. Light passes through polarizers and the liquid-crystal layer, which modulates its intensity.

Visibility is dependent on the backlight (without it, the screen is dark). Full color reproduction and sharp detail are achievable in TFT/IPS resolutions. Typical luminance for industrial displays ranges from 400 to 600 nits, but in sunlight readable environment backlight intensity goes up to 1500 nits and above. Riverdi standard displays are between 800 to 1000 nits. For more backlight we can make a customized solution.

Common applications (Smartphones, Monitors, TVs)

Transmissive technology dominates in:

- operator panels and control room displays in factories,

- stationary terminals and warehouse displays,

- smartphones and tablets,

- office and graphics monitors,

- LCD/LED televisions,

- indoor multimedia panels.

It’s the best choice when you need deep and saturated colors, high resolution, consistent image quality at all viewing angles.

When to choose a transflective LCD display?

Transflective LCDs are designed for devices exposed to variable or extreme lighting. They work well wherever a device must remain readable in full sunlight while running on battery for hours.

How transflective technology works (Hybrid)

Unlike standard transmissive designs, a transflective panel includes a unique component: the transflector, a semi-reflective polarizer layer. It operates in two modes.

In darkness it transmits LED backlight, functioning like a typical transmissive display. In daylight – it reflects ambient light, generating an image without using the backlight at all.

Result: visibility increases as sunlight becomes stronger.

Key advantages: all-condition visibility & power savings

Transflective LCDs offer excellent readability in direct sunlight, low power consumption during daytime operation, long battery life and resistance to temperature variations, vibration, and moisture.

This is a technology built for the field.

Main disadvantages

Despite its significant advantages, this technology, like any other, has its limitations. Colors and contrast in reflective mode are lower and panel manufacturing is more complex and costly.

Common applications (Industrial, Medical, Navigation)

Transflective LCDs are chosen when lighting conditions are variable or extreme:

- industrial and mobile terminals,

- barcode readers, scanners, handhelds,

- medical devices used outdoors,

- automotive, marine, and aviation GPS units,

- outdoor and IoT equipment.

Head-to-head comparison: transmissive vs. transflective

| Feature | Transmissive LCD | Transflective LCD |

| Light source | Backlight LED required in all conditions | Hybrid: backlight + ambient light reflection (transflector) |

| Color quality | Very high, full color range | Moderate; reflective mode reduces contrast and saturation |

| Sunlight visibility | Limited; relies on strong backlight | Excellent; sunlight enhances readability |

| Power consumption | Higher due to constant backlight | Lower in daytime; backlight can be dimmed or switched off |

| Typical industrial use | Stationary devices, operator panels, indoor use | Mobile terminals, field devices, outdoor equipment, navigation |

Which technology is better for your project?

The best choice depends on the working environment and project priorities. Riverdi customers and engineer teams often decide as follows.

| Transmissive LCD – indoor devices where color accuracy and high resolution are most important. | Transflective LCD – mobile or outdoor devices where sunlight readability, power efficiency, and durability are key. |

| Operator panels and control consoles in production halls

Stationary industrial terminals and monitoring displays

Displays in building automation systems (BMS)

Data visualization systems in laboratories and quality control centers | Portable terminals and barcode scanners in warehouses and logistics

Mobile medical devices used outdoors

GPS and navigation systems in automotive, marine, and aviation applications

IoT sensors and displays in harsh outdoor environments

Field devices for utilities, telecommunications, and on-site service teams |

Riverdi’s standard offering is based on transmissive TFT IPS LCDs—the most commonly chosen technology due to their reliability, stability, and high image quality.

At the same time, if your project requires something different, we can design a customized solution suited to your application. Contact our engineering team, and we’ll help you find the perfect fit.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!