Touch interaction with electronic devices has become ubiquitous. From smartphones and tablets, through ATMs, to industrial control panels – touchscreens are an integral part of our lives. The complexity of the technologies hidden beneath the glass is often underestimated. Precise, responsive, and reliable operation requires advanced engineering. This article aims to explain the working principles, evolution, and specific properties of different touchscreen technologies, including capacitive, resistive, infrared, and acoustic screens.

What is a touchscreen?

A touchscreen is an integrated input-output interface that combines display functionality with the ability to input data through touch. The key task of this system is to precisely determine the coordinates of the contact point and then convert them into a digital signal understood by the device’s processor.

It should be emphasized that basic touch systems do not measure pressure, but only the location of contact. The method by which this location is detected defines the classification of the touchscreen technology.

History of touchscreens

The first work on touch interfaces dates back to the 1960s. In 1965, Eric Johnson from the Royal Radar Establishment described the concept of a capacitive touchscreen, which laid the theoretical foundation for this technology. However, the first working prototype of a resistive touchscreen was created only in 1974 at the University of Kentucky.

The 1980s and 1990s were the period of commercialization of resistive technology, which was used in medical and industrial devices. A key moment in touchscreen history was the launch of the iPhone in 2007. This device popularized capacitive screens with multi-touch functionality, revolutionizing the way consumers interact with mobile technology.

Capacitive touchscreens

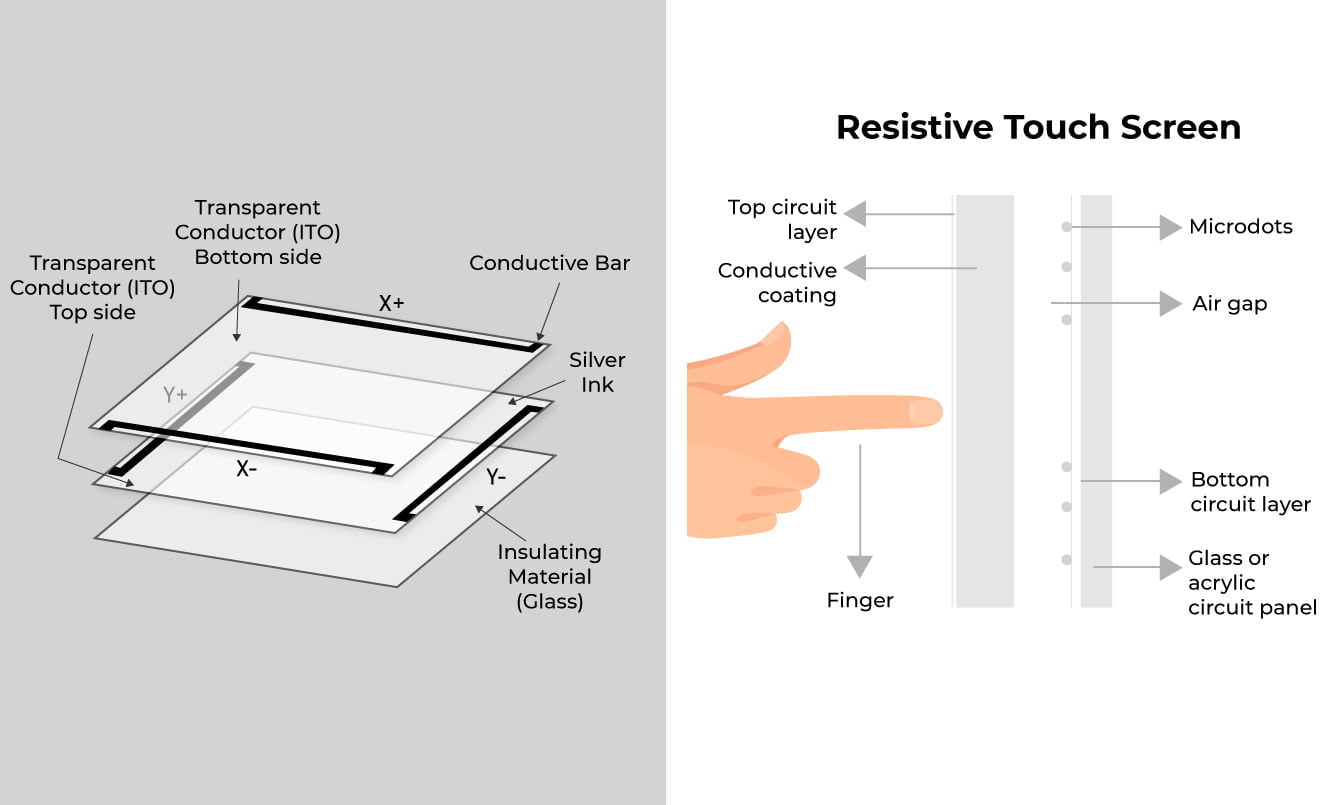

Capacitive screens operate based on the electrostatic properties of the human body. The surface of the screen is covered with a transparent conductive layer (usually ITO – indium tin oxide). A constant voltage is maintained on the edges of the screen. Touching the surface with a finger, which is a conductor, disturbs the electrostatic field. Sensors placed on the edges or in a grid of electrodes detect changes in capacitance at the point of touch and use this data to precisely determine the coordinates.

- Advantages – high precision and sensitivity, support for multi-touch gestures, no need for physical pressure, high durability and scratch resistance, high transparency of the layers resulting in excellent image quality.

- Disadvantages – no response to touch with regular gloves or non-conductive styluses, sensitivity to electromagnetic interference in certain environments.

Modern devices commonly use projected capacitive (P-CAP) screens, which use an electrode grid on the X and Y axes. This architecture allows simultaneous detection of multiple touch points and operation under thick protective glass layers.

Resistive touchscreens

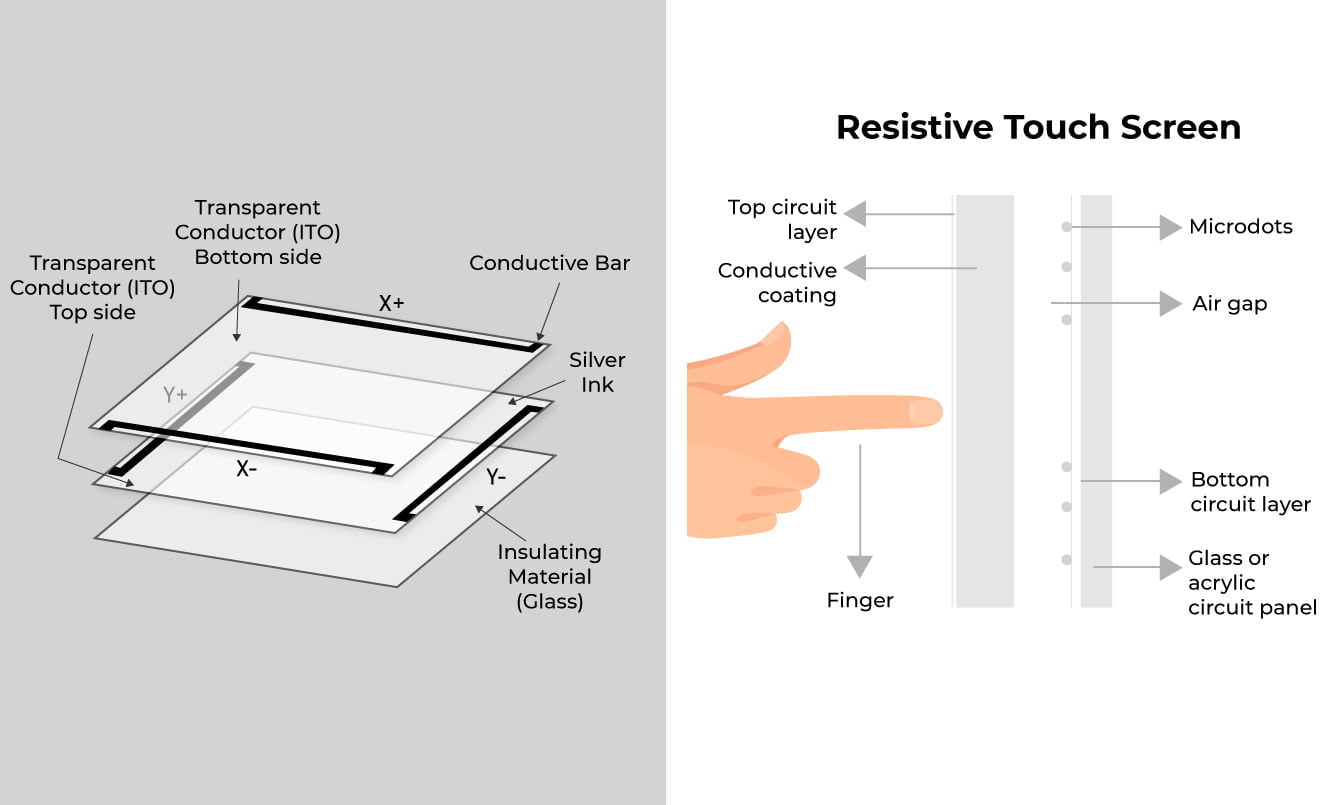

Resistive technology is based on pressure detection. The screen consists of two flexible conductive layers, separated by microscopic spacer dots. When the user presses the surface, the layers touch at the contact point, closing the circuit. The electronic system measures the electrical resistance along the X and Y axes, which allows accurate determination of the touch coordinates.

- Advantages – can interact with any object (finger, glove, stylus), immune to electromagnetic interference, lower production cost.

- Disadvantages – requires physical pressure, which may affect the durability of the top layer, no native multi-touch support, additional layers reduce transparency and display contrast.

Resistive screens are still widely used in POS (point-of-sale) systems, industrial terminals, ticket machines, and older navigation devices.

Infrared touchscreens

The IR system does not integrate touch layers on the display. Emitters and detectors of infrared light are placed in the frame around the screen, forming an invisible grid of beams. Touching the screen interrupts the light beams. The system uses information about the interrupted rays to precisely determine the coordinates of the touch point.

- Advantages – no layers applied on the screen, ensuring excellent image quality, high durability (no wearing elements), can interact with any object.

- Disadvantages – sensitivity to dust and contaminants that can interfere with the beams, larger frame size, higher costs compared to capacitive technology.

IR screens are ideal for large interactive installations, such as information kiosks, educational boards, or interactive tables.

Surface Acoustic Wave (SAW) Touchscreens

SAW technology is based on the propagation of ultrasonic waves across the surface of the glass screen. Transducers mounted on the edges generate and receive acoustic waves. Touching the screen absorbs part of the wave energy, which is detected by sensors. Based on the signal attenuation, the system precisely locates the touch point.

- Advantages – high optical quality, as the technology does not require additional layers; natural touch feel; high precision.

- Disadvantages – no response to hard objects (e.g., fingernail), sensitivity to liquids or contamination on the surface, not suitable for mobile devices due to sensitivity to shock.

SAW is used in specialized information terminals, ATMs, and control systems where image clarity is critical.

Summary

| Technology | Principle of Operation | Pros | Cons | Applications |

| Capacitive | Detects changes in an electrostatic field when a conductive object (like a finger) touches the screen. | High precision, multi-touch support, excellent image quality. | Doesn’t work with regular gloves, sensitive to EMI. | Smartphones, tablets, modern monitors. |

| Resistive | Two flexible conductive layers touch under pressure, closing a circuit. The system measures resistance at the contact point. | Works with any object (finger, stylus, gloved hand), immune to EMI, low cost. | Requires physical pressure, no multi-touch, lower image quality, less durable. | POS systems, industrial terminals, ATMs. |

| Infrared (IR) | An array of emitters and detectors in the frame creates an invisible IR light grid. A touch interrupts the beams. | Excellent image quality, high durability, works with any object. | Sensitive to dust, larger bezels, higher cost. | Information kiosks, educational boards, large displays. |

| Surface Acoustic Wave (SAW) | Ultrasonic waves propagate across the glass surface. A touch absorbs wave energy, which is detected by sensors. | High optical quality, natural touch feel, high precision. | Doesn’t work with hard objects, sensitive to dirt/liquids, not for mobile devices. | Specialized terminals, ATMs, control systems. |

The selection of touchscreen technology is dictated by the specific requirements of the application. While engineers balance between cost, durability, and sensitivity, the user primarily values intuitive and reliable interaction. This technological diversity is key to delivering optimal solutions across different sectors – from dynamic mobile interfaces to industrial panels.

Contact our engineers. We’ll help you select a touchscreen that matches your application and ensures optimal performance in real-world conditions.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!