If you’ve been specifying displays lately, you’ve probably encountered the acronym soup: OLED, AMOLED, PMOLED. While marketing teams love throwing these terms around interchangeably, there are real engineering differences that matter when you’re choosing the right display for your project.

The initial confusion might be understandable. Both technologies use organic materials that emit light when current flows through them. But the devil’s in the implementation details—and those details can do wonders or put a curse on the effectiveness of your design.

What is OLED?

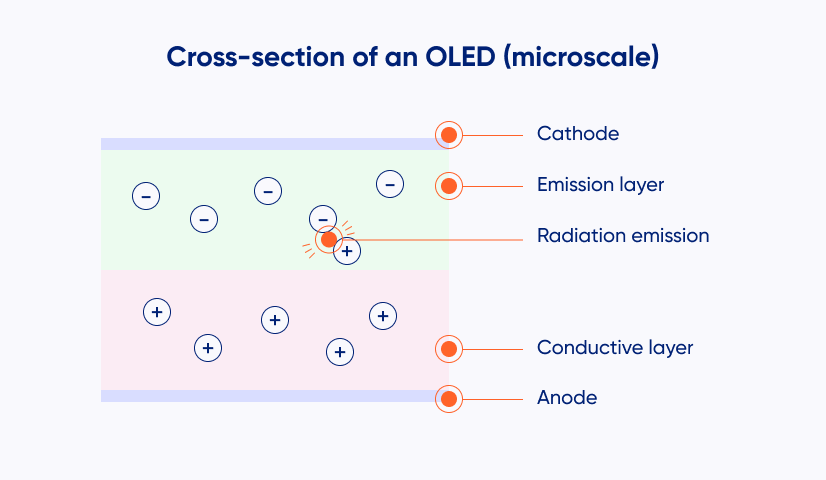

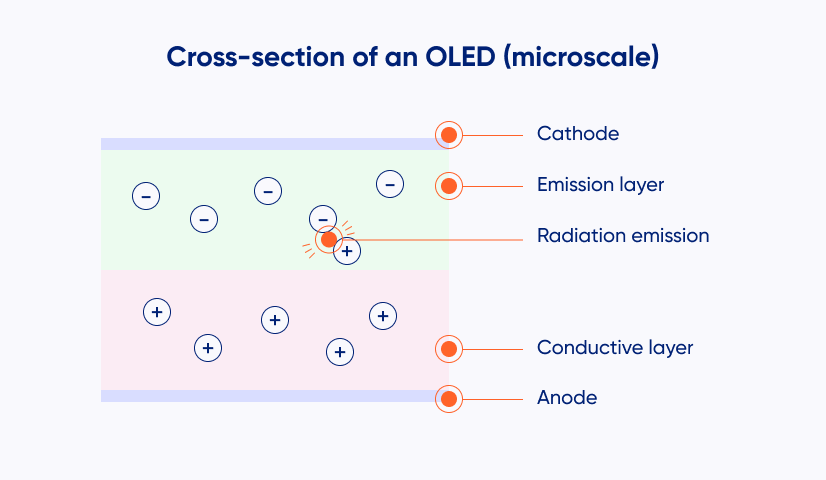

OLED stands for Organic Light-Emitting Diode. At its heart, it’s surprisingly simple: organic compounds sandwiched between two electrodes that emit photons when you apply voltage. No backlight needed, no color filters required—just direct light emission from the organic material itself.

This fundamental approach gives OLED displays their signature characteristics: perfect blacks (pixels simply turn off), excellent contrast ratios, and the ability to be manufactured on flexible substrates. It’s why your smartphone can bend slightly without the display cracking, and why OLED TVs can achieve those dramatic dark scenes that make LCD look washed out.

How does OLED work?

The physics are straightforward—no Schrödinger’s cats involved. Apply current to organic molecules, and they jump to higher energy states. As they return to their ground state, they emit photons. Different organic compounds emit different wavelengths—red, green, or blue—enabling full-color displays.

The clever part is the structure. You’ve got a substrate (usually glass), an anode layer, the organic emissive layer, a cathode, and encapsulation to protect the sensitive organics from moisture and oxygen. It’s a much simpler stack than LCD displays, which need backlights, diffusers, polarizers, and color filters.

Cross-section of an OLED (microscale)

What is AMOLED?

Can “better” get even better? Of course. This is the case of AMOLED which is OLED with a crucial addition: Active Matrix control. Think of it as putting a tiny memory cell and switch at every pixel location. This isn’t just a nice-to-have feature—it fundamentally changes what’s possible with the display.

The “Active Matrix” part refers to the thin-film transistor (TFT) backplane that controls each pixel independently. This is the same basic approach used in modern LCD panels, but applied to OLED technology.

And yes, better than “even better” is possible too. It’s called Super AMOLED—a more advanced AMOLED variant with touch sensors integrated directly into the screen. This eliminates the separate touch layer, boosting brightness, improving sunlight readability, and reducing power consumption.

How does AMOLED work?

Each pixel location contains a driving circuit with transistors that store and maintain the pixel’s brightness level between refresh cycles. During addressing, the row select transistor turns on, allowing the pixel’s storage capacitor to charge to the desired voltage level. Once charged, the pixel maintains its state until the next refresh.

This stored-charge approach means pixels can emit light continuously rather than being pulsed during brief addressing windows. The result is brighter displays with more consistent brightness across the entire screen area.

Differences between OLED and AMOLED

The distinction is neither academic nor marketing-related—it has real implications for your design choices.

Scalability: Passive OLED (PMOLED) works well up to about 5 inches diagonal. Beyond that, you run into fundamental physics problems with line resistance and pixel duty cycle. AMOLED scales to whatever size you can afford to manufacture.

Power consumption: PMOLED must drive entire rows and columns simultaneously, leading to high peak currents and power waste. AMOLED pixels draw power only when and how much they need it.

Refresh rates: PMOLED struggles with fast-moving content because each pixel only gets a tiny fraction of the refresh cycle to emit light. AMOLED pixels stay on continuously, enabling smooth video and responsive touch interfaces—with extremely fast refresh rates reaching 120Hz or higher. The same with touch sampling rates reaching up to 240Hz which is a great advantage for industrial HMIs.

Manufacturing complexity: PMOLED is simpler to make—just pattern the OLED materials between row and column electrodes. AMOLED requires a full TFT backplane, making it more expensive but also more capable.

Resolution limits: PMOLED tops out around 256×64 pixels for practical applications. AMOLED can handle 4K and beyond.

Thinness, lightness and flexibility: The active matrix in AMOLED allows for even thinner displays that can also be bent and folded.

What’s better: AMOLED vs. OLED?

This is where engineering reality meets marketing speak. Technically, AMOLED is a subset of OLED—you can’t have AMOLED without OLED. But in practical terms, the question usually comes down to PMOLED versus AMOLED.

For simple status displays, basic HMIs, or cost-sensitive applications, PMOLED often makes sense. You get the OLED advantages of high contrast and wide viewing angles without the complexity of active matrix addressing. Think fitness tracker displays, small instrument panels, or simple indicator lights where you’re showing mostly static information.

But for anything involving video, large screen sizes, high resolution, or complex graphics, AMOLED is the clear winner. The active matrix control enables the performance characteristics that make modern smartphones and industrial HMIs possible.

From a systems perspective, AMOLED also offers better integration with modern graphics controllers. The display interfaces (MIPI DSI, RGB, etc.) are standardized and well-supported. PMOLED often requires custom controller logic and careful timing management.

The real decision point usually comes down to your specific requirements: screen size, resolution, update rate, and budget. If you need more than basic text and simple graphics on anything larger than a few inches, AMOLED is probably your path forward. For everything else, PMOLED might be the more pragmatic choice.

Ready to make the right choice?

Or maybe still hesitating which technology suits your project?

Talk to our engineering team. We’re here to help you choose and customize the right display based on your specific application.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!