In this Display 101 article we’re focusing on a certain construction detail – the cover glass.

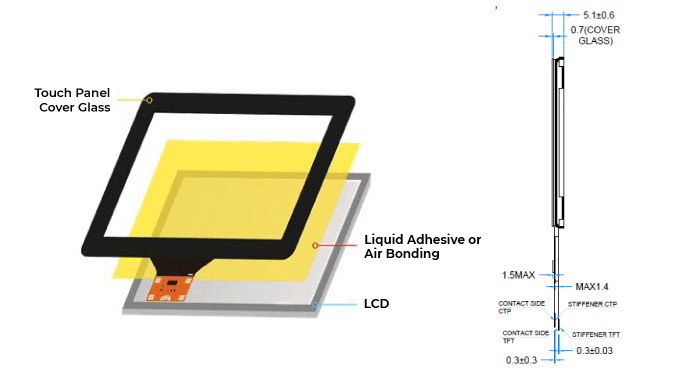

The first thing we should point out is that modules with projected capacitive touch panels have a top layer, called a cover. This part of the module is the most often customized component of the product.

The thickness of the cover glass depends on the size of the display. Below is a table with recommended thickness values (implemented on Riverdi display modules):

Recommended cover glass thickness

| Display size | Glass thickness | The Touch panel thickness |

| 2.8″ | 0.7mm | 1.4mm |

| 3.5″ | 0.7mm | 1.4mm |

| 4.3″ | 0.7mm | 1.4mm |

| 5.0″ | 0.7mm | 1.4mm |

| 7.0″ | 1.1mm | 1.8mm |

The thickness values above are recommended for standard solutions. However, for special requirements, there are available different glass thickness options, such as 0.55mm, 0.7mm, 1mm, 1.8mm.

If your project requires thicker glass, feel free to contact us!

We use HYCON controllers, which support cover glass up to 5 mm of thickness! For more info about the HYCON controller please check this article.

True colors

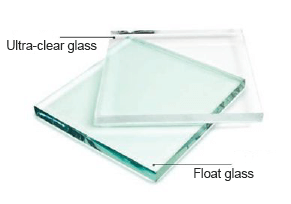

Riverdi displays always present clear and vibrant images. Colors remain sharp and true despite using thick cover glass. We achieve this effect by choosing an ultra-clear cover glass solution for the display.

This means, that the component is absolutely discolored (like in the picture below).

The safety aspect of the glass

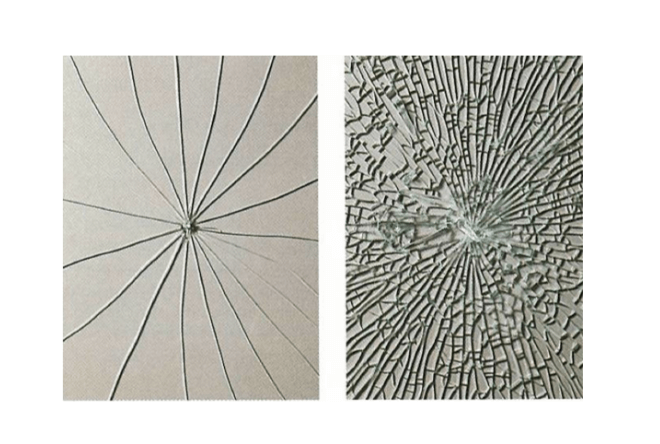

The second aspect of the designing process is the safety of the glass. The two most popular options are:

- Chemically strengthened glass

- Thermally tempered glass

Both options have increased strength as the result of a post-production process (as the names suggest – the chemical or thermal treatment).

When chemically tempered glass gets broken, it shatters in long splinters, unlike regular glass. The appearance of the structure after breaking of the thermally tempered glass is different – it crumbles into smaller, granular chunks.

What if there was no glass?

In most cases, the “cover glass” is actually made out of glass. So, obviously, that is where the name comes from. But it can be made out of other materials as well.

The cover glass on Riverdi displays provides 6H≤ hardness at the very top layer of the module. Of course, as we said above, it also provides great transparency.

A good alternative for cover glass is PMMA (Polymethylmethacrylate).

The PMMA is transparent thermoplastic. It is softer material than the glass (hardness 3H≤), also less transparent. The dielectric constant is lower, so to keep the same performance the thickness must be half like the glass. The PMMA is a good solution for the industrial and rugged environment.

We hope you enjoyed our lesson on display cover glass. Stay tuned for another interesting lesson on smart displays next week.

DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!