DISCOVER OUR

Whitepaper

Achieve the perfect user-display interaction with the right Touch Sensor IC. Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper!

Description

A high-resolution, high-brightness, IPS TFT displays that’s been enhanced with optical / air bonding and an industrial touch screen. It comes with the following advantages:

Plug and play HDMI interface

The HDMI interface is extremely popular enabling connection to any external HDMI input source. The display will be detected automatically and can act as a system monitor; it can be connected directly to a PC (Windows/Linux) or any SBC (i.e. Raspberry Pi).

Plug and play USB-C touch solution

USB-C, the universal and symmetric connector, provides an easy solution for power supply, touch and other data transfer all in one. There are no external drivers required.

Internal and external backlight PWM control with multi-functional OSD menu

You can adjust: brightness, contrast, saturation. Additionally there is an external keyboard connector should you need to have an additional one.

High brightness, IPS TFT

Typical surface luminance for a high brightness, IPS TFT displays is 800 up to 1000 cd/m² which means it is very bright even outdoors. The full viewing angles allow the user to interact with the display in a natural and intuitive way from every side. Please see the datasheet for more features.

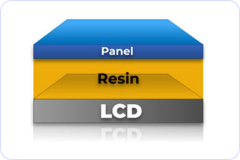

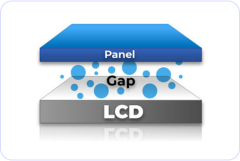

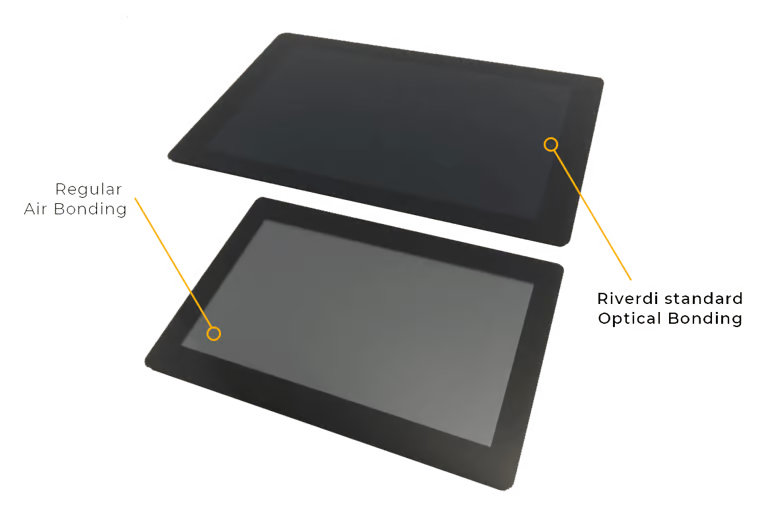

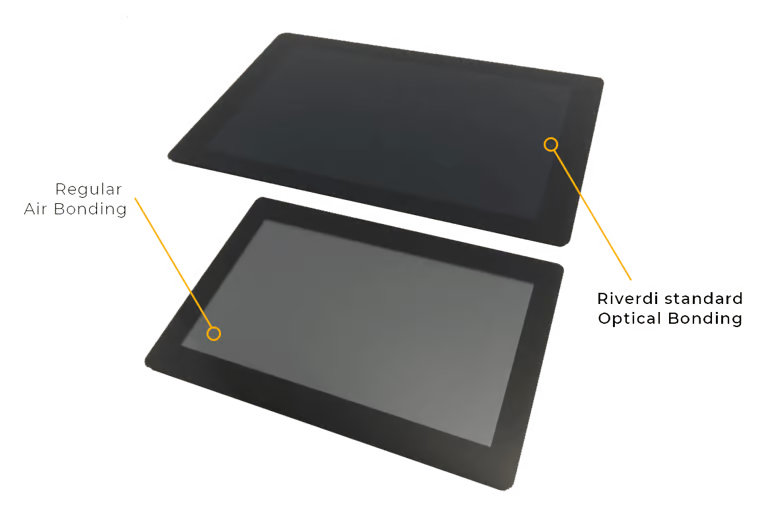

Optical / Air Bonding

Enhancing the optical performance of your display

Optical bonding is a process of affixing the touch panel (or just the protective glass) to the display using a liquid adhesive, gel or dry (film). In general, this process improves the parameters of the module – the optical performance, as well as durability.

The air-gap is the reason for the phenomena of reflection of sunlight. So, when the display is off, the Visual Area (V.A) is never black – it is gray.

When removing the air gaps, we reduce the number of internal reflecting surfaces, which increase of optical performance. This phenomenon improves readability, by reducing the reflection and correct contrast.

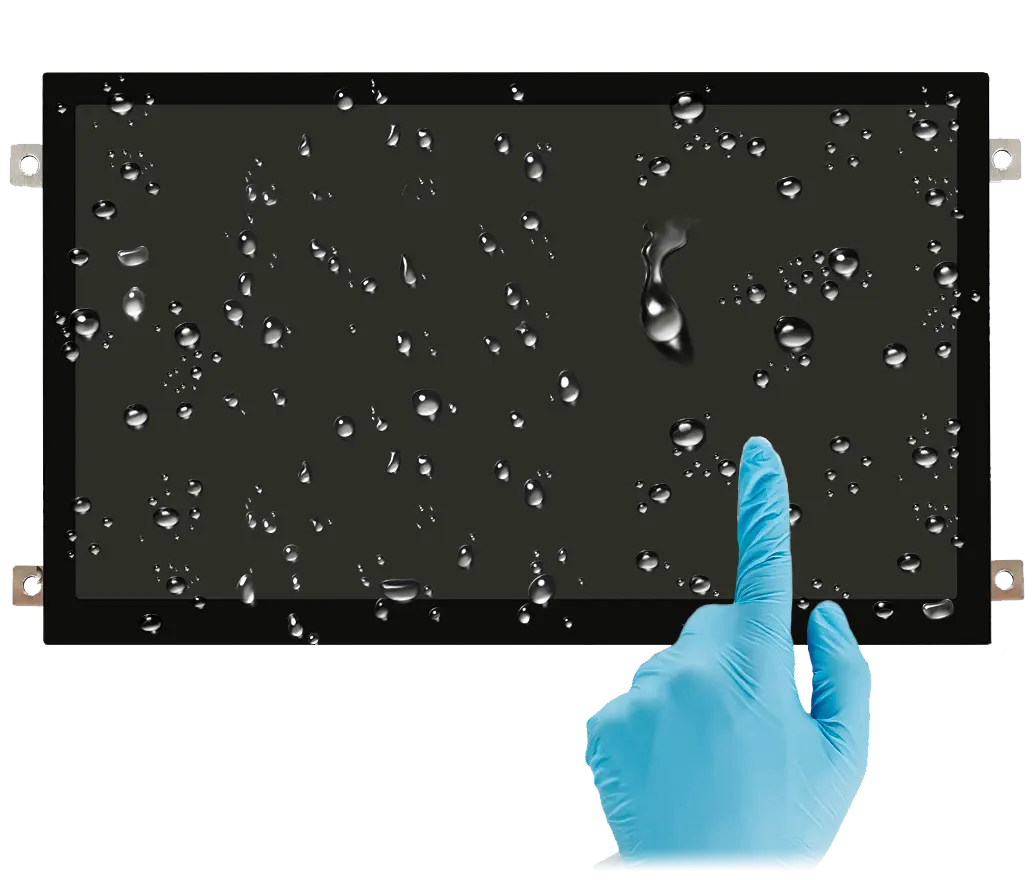

Industrial Touch Screen

Reacts to the slightest touch

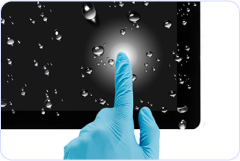

The PCAP (Projected Capacity touch panel) is classified as ‘industrial’ (as opposed to ‘consumer’) when it is able to operate correctly in more demanding, harsh conditions (i.e. disturbing electromagnetic fields around causing interferences with panel controller, water droplets present in the surrounding area also on panel glass), and react properly when touched by hands in gloves. It can be tuned at the factory, detect touch through thicker glass layers than consumer panels (6mm thick glass layer was tested with success in the Riverdi lab) and it uses an industrial grade chip controller. Such controllers have industrial manufacturer’s guidelines implemented and are guaranteed to be manufactured typically from 10 to 15 years.

Main features:

- ILITEK Touch IC-ILI2132A, with 10 years guaranteed availability

- USB/I²C interface

- Supports cover glass thickness up to 8 mm*

- Supports thick gloves operation (i.e. double gloves, tactical gloves)*

- Working with water on the surface

- Multi-touch, up to 10 points

- Great EMC, RS (radiated susceptibility) and CS (conductive susceptibility) performance

*Riverdi is skilled to adjust parameters up to specific needs (thicker gloves, thicker glass)

Traditional shape with modern functionality

aTouch was designed to provide the functionality of a modern Projected Capacitive Touch panel in a traditional shape and size perfect for an upgrade of an older device. Thanks to the absolute flat design and multi-touch feature, it will significantly raise the value of any project. It features chemically strengthened glass, which has increased durability, thanks to the process of ion-exchange. They are easy to assemble, easy to clean and easy to implement into your design.

Newly built devices most often use the uxTouch panel which is stuck to the outside of the device and is slightly larger than the display – it looks nice and modern. However, in older devices that only need an upgrade, the panel needs to be the same size as the display. Thus, there are many customers who require the solution provided by aTouch in order to mount the display from the inside into the classic hole.

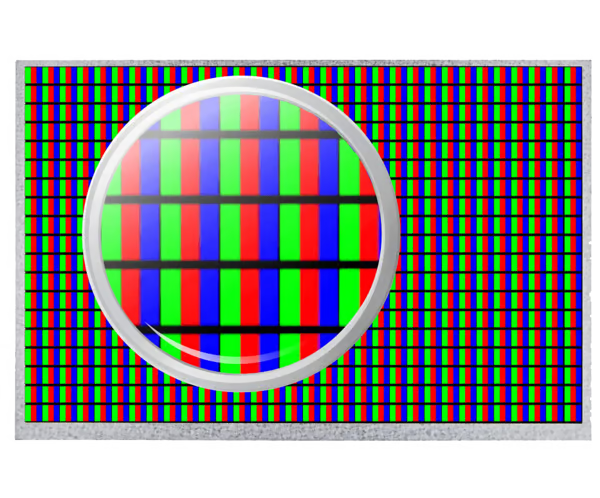

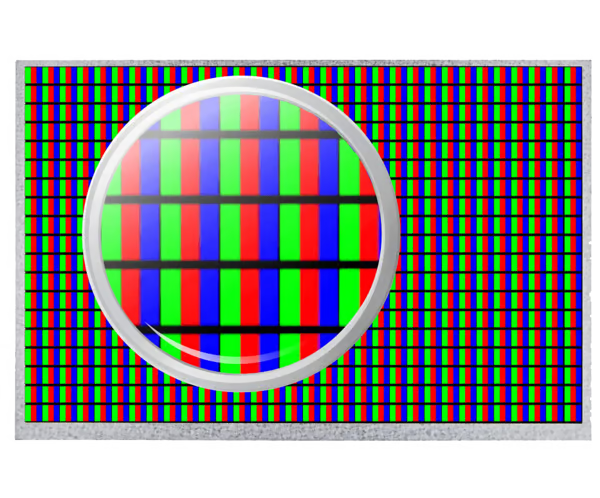

Glass in displays comes from TFT factories in large sheets called mother glass and is sorted by classes. These classes are governed by ISO standards which identify three levels of allowable number of bad pixels.

Apart from the visual discomfort bad pixels cause, there are very important practical disadvantages to working on a screen missing a seemingly tiny dot. The importance will vary across industries but it is perhaps best illustrated in medical devices where even a single bad pixel may change image enough to lead to wrong conclusions and dramatic consequences.

In our 10.1” displays we add an additional layer of tests as standard so we do not miss a single item with a bad pixel. There is a 100% ZERO bad pixels guarantee.

Customized displays

You can customize displays in many different ways.

- Change the color, shape, and size of the cover glass

- Have your logo printed on the cover glass (or any other graphics you might need)

- Add a different interface

- Enhance the brightness of the screen

- Change the thickness of the cover lens for the CTP

- Choose a different viewing angle of the display

- Change the pinout

- Request different gasket assembly

As you can see the possibilities are endless. All you need to do is choose.

We will help you to get the perfect tailor-made product.